Woven Bag

Understanding the 50kg Woven Bag Packing Machine

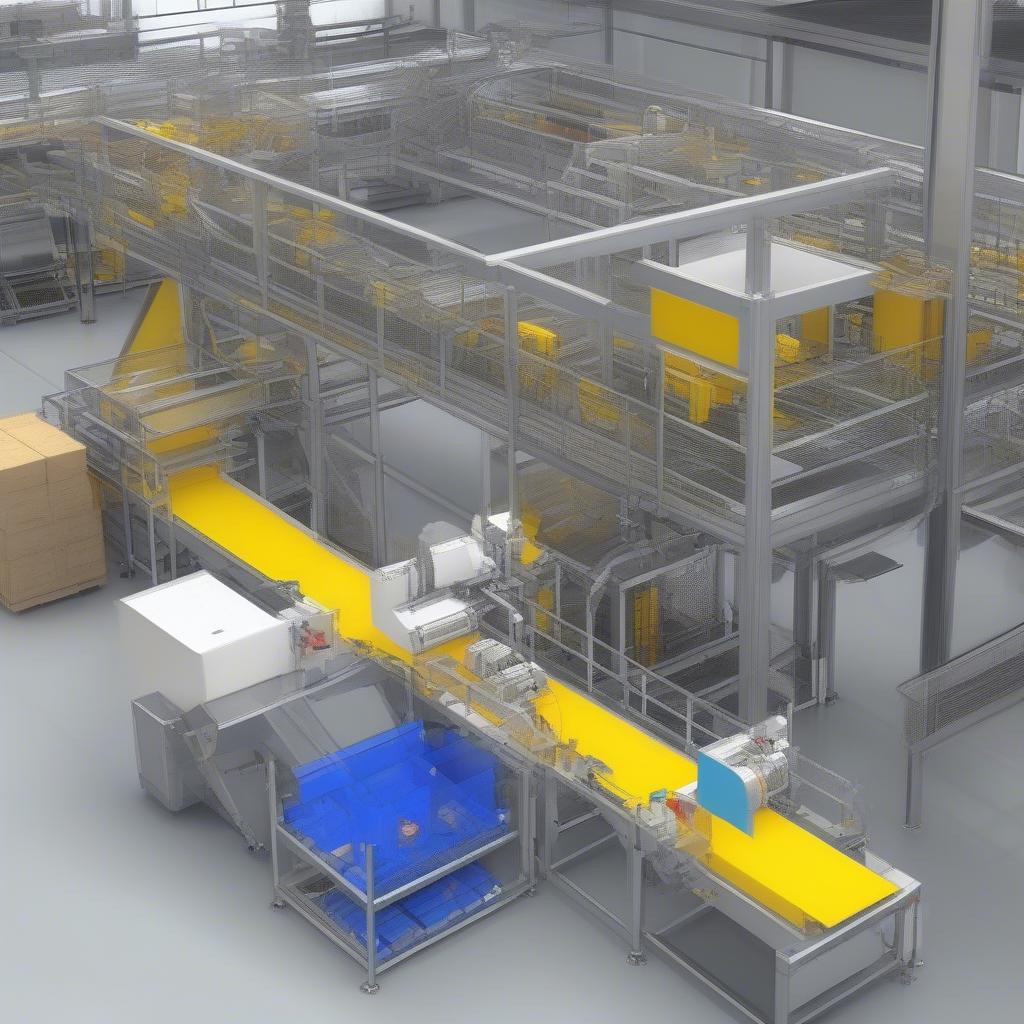

A 50kg woven bag packing machine is a crucial piece of equipment for businesses dealing with bulk materials, offering efficient and automated packaging solutions. These machines are designed to fill and seal woven bags, commonly used for products like grains, fertilizers, animal feed, and construction materials. Understanding the different types, features, and benefits of these machines can significantly impact your packaging operations.

Types of 50kg Woven Bag Packing Machines

There are various types of 50kg woven bag packing machines, each designed for specific needs and materials. Some common types include:

- Gross Weight Fillers: These machines fill bags based on a predetermined target weight. They are simple to operate and suitable for free-flowing materials.

- Net Weight Fillers: Offering greater accuracy, these machines weigh the material as it fills the bag, ensuring precise filling and minimizing product waste. Ideal for more expensive materials where accuracy is paramount.

- Open-Mouth Baggers: Designed for open-mouth woven bags, these machines automate the filling and closing process.

- Valve Bag Fillers: Specifically designed for valve bags, these machines utilize the bag’s built-in valve for filling, eliminating the need for a separate sealing process.

Benefits of Using a 50kg Woven Bag Packing Machine

Investing in a 50kg woven bag packing machine offers several advantages:

- Increased Productivity: Automating the packaging process significantly increases output compared to manual filling, saving time and labor costs.

- Improved Accuracy: Automated systems ensure consistent and precise filling, reducing product giveaway and improving cost efficiency.

- Reduced Labor Costs: Automation minimizes the need for manual labor, freeing up employees for other tasks and reducing overall labor expenses.

- Enhanced Safety: Automated systems minimize human interaction with heavy materials, reducing the risk of workplace injuries.

- Better Hygiene: Automated packaging helps maintain product hygiene and quality, especially crucial for food and agricultural products.

Types of 50kg Woven Bag Packing Machines

Types of 50kg Woven Bag Packing Machines

Key Features to Consider

When selecting a 50kg woven bag packing machine, consider these features:

- Bag Type Compatibility: Ensure the machine is compatible with the type of woven bags you use (open-mouth, valve, etc.).

- Filling Speed and Capacity: Choose a machine with the appropriate filling speed and capacity to meet your production requirements.

- Weight Accuracy: Consider the required level of accuracy for your specific product.

- Automation Level: Determine the desired level of automation for bag handling, filling, and sealing.

- Maintenance and Durability: Opt for a machine with easy maintenance requirements and robust construction for long-term reliability.

Integrating the 50kg Woven Bag Packing Machine into Your Workflow

Successfully integrating a 50kg woven bag packing machine requires careful planning and consideration:

- Assess your current packaging process: Identify bottlenecks and areas for improvement.

- Determine your production needs: Calculate your required throughput and bagging capacity.

- Choose the right machine: Select a machine that meets your specific needs and budget.

- Plan for installation and training: Ensure proper installation and training for operators.

- Regular maintenance and servicing: Implement a preventative maintenance schedule to ensure optimal performance.

Integrating a 50kg Woven Bag Packing Machine

Integrating a 50kg Woven Bag Packing Machine

“Investing in a reliable 50kg woven bag packing machine can be a game-changer for businesses looking to improve their packaging efficiency and reduce costs,” says John Miller, Senior Packaging Engineer at Packaging Solutions Inc. “The key is to choose a machine that aligns with your specific needs and production goals.”

Choosing the Right Supplier

Choosing the right supplier is crucial for a successful investment. Look for suppliers who offer:

- Experience and Expertise: Choose a supplier with a proven track record in providing high-quality packaging solutions.

- Comprehensive Support: Ensure the supplier offers installation, training, and ongoing maintenance support.

- Customization Options: Consider suppliers who offer customization options to tailor the machine to your unique needs.

“Working with a reputable supplier is essential for maximizing the benefits of your 50kg woven bag packing machine,” adds Sarah Lee, Packaging Consultant at Industrial Automation Group. “A good supplier will provide the necessary support and guidance to ensure smooth integration and optimal performance.”

In conclusion, a 50kg woven bag packing machine is a valuable investment for businesses handling bulk materials. By carefully considering the different types, features, and supplier options, you can choose the right machine to optimize your packaging process and improve your bottom line.

FAQ:

- What is the average lifespan of a 50kg woven bag packing machine?

- What types of maintenance are required for these machines?

- How much space is needed to install a 50kg woven bag packing machine?

- What safety features should I look for in a 50kg woven bag packing machine?

- What are the typical power requirements for these machines?

- How do I choose the right bag size for my product?

- What is the warranty period for a typical 50kg woven bag packing machine?

For further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.