Weave Hat

China Hat Weaving Machine: A Deep Dive into Automated Conical Hat Production

China Hat Weaving Machines have revolutionized the production of these iconic conical hats. These machines offer a blend of speed, precision, and efficiency, transforming the traditional craft into a modern manufacturing process. From understanding the mechanics to exploring the impact on the industry, this article will delve into every aspect of china hat weaving machines.

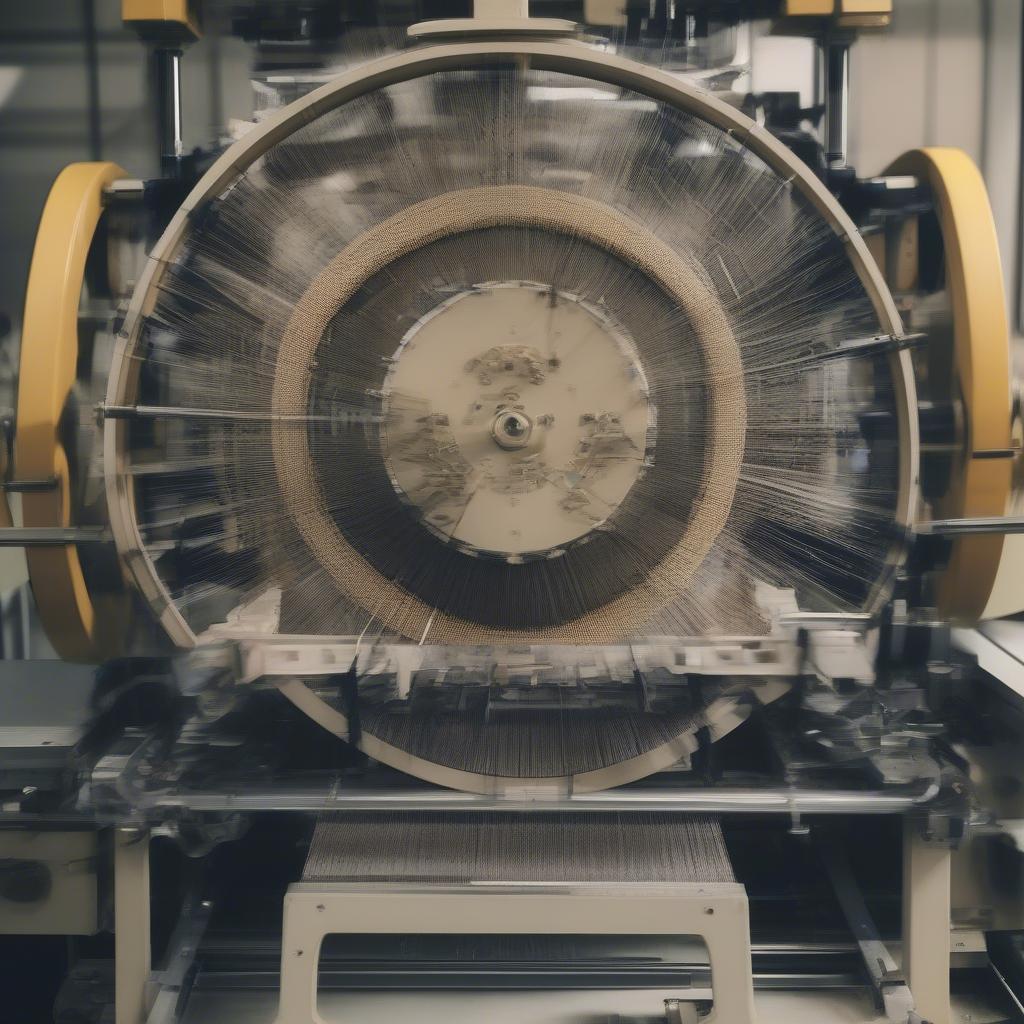

Understanding the Mechanics of a China Hat Weaving Machine

China hat weaving machines, also known as conical hat making machines, automate the intricate process of weaving these distinctive headwear. They operate on a principle of rotating mandrels and automated needle systems, mimicking the hand movements of traditional artisans. The machine precisely interlaces natural materials like bamboo, palm leaves, or other suitable fibers to create the hat’s conical shape.  China hat weaving machine mechanics: Close-up view of the rotating mandrel and automated needle system interlacing bamboo fibers to form the conical shape of the hat. This automated process allows for consistent quality and increased production speeds compared to manual weaving.

China hat weaving machine mechanics: Close-up view of the rotating mandrel and automated needle system interlacing bamboo fibers to form the conical shape of the hat. This automated process allows for consistent quality and increased production speeds compared to manual weaving.

Advantages of Using a China Hat Weaving Machine

The benefits of using a china hat weaving machine are numerous. They significantly increase production capacity, allowing businesses to meet higher demands.  China hat weaving machine advantages: Comparison of manual hat weaving and machine-made hat weaving, showcasing the increased production capacity and consistent quality of machine-made hats. The machines also ensure consistent quality, minimizing variations that can occur with manual production. This consistency is crucial for businesses looking to maintain brand standards and customer satisfaction. Furthermore, these machines can create more intricate and complex designs, expanding the possibilities for hat styles and aesthetics.

China hat weaving machine advantages: Comparison of manual hat weaving and machine-made hat weaving, showcasing the increased production capacity and consistent quality of machine-made hats. The machines also ensure consistent quality, minimizing variations that can occur with manual production. This consistency is crucial for businesses looking to maintain brand standards and customer satisfaction. Furthermore, these machines can create more intricate and complex designs, expanding the possibilities for hat styles and aesthetics.

Impact of China Hat Weaving Machines on the Industry

The introduction of china hat weaving machines has had a profound impact on the conical hat industry. While some argue that it detracts from the traditional craft, others see it as a necessary evolution. These machines have undoubtedly increased affordability and accessibility, making these beautiful hats available to a wider audience. They have also allowed businesses to scale their operations, contributing to economic growth in regions where hat making is a significant industry. However, it is essential to acknowledge the potential displacement of traditional artisans. Finding a balance between embracing technological advancements and preserving traditional skills is a crucial challenge facing the industry.  China hat weaving machine impact: A graph illustrating the increase in conical hat production and affordability after the introduction of weaving machines.

China hat weaving machine impact: A graph illustrating the increase in conical hat production and affordability after the introduction of weaving machines.

Choosing the Right China Hat Weaving Machine

Selecting the appropriate china hat weaving machine depends on several factors, including production volume, budget, and desired hat styles. Some machines are designed for smaller-scale operations, while others are suited for large-scale industrial production. Features like adjustable mandrel sizes and customizable weaving patterns also influence the choice. Researching different manufacturers and models, considering user reviews, and seeking expert advice can help businesses make informed decisions.

How Does a China Hat Weaving Machine Work?

China hat weaving machines use a combination of rotating mandrels and automated needle systems to weave conical hats. The mandrel determines the hat’s shape, while the needles interlace the chosen material. The process is highly automated, requiring minimal human intervention.

What Materials Can Be Used with a China Hat Weaving Machine?

Various natural fibers, including bamboo, palm leaves, and straw, can be used with these machines. The choice of material affects the hat’s final appearance, durability, and cultural significance.

Are China Hat Weaving Machines Difficult to Operate?

While the mechanics are complex, modern china hat weaving machines are designed for user-friendliness. Training is typically provided by manufacturers, enabling operators to learn the necessary skills.

Conclusion

China hat weaving machines have revolutionized the production of these iconic hats. While maintaining a respect for tradition, these machines offer efficiency and increased production capabilities. Understanding the mechanics, advantages, and impact of these machines is crucial for anyone involved in the conical hat industry. For more information or assistance, please contact our hotline at +84 388 951 999, visit our office in Hanoi, Vietnam, or our US office at Tech Avenue, Suite 12, San Francisco, CA 94105. We offer 24/7 customer support.