Woven Bag

Non Woven Bag Screen Printing Ink: A Comprehensive Guide

Non Woven Bag Screen Printing Ink is crucial for creating vibrant and durable designs on non-woven bags. This guide dives into the world of inks for non-woven fabrics, exploring their properties, application techniques, and best practices for achieving professional results. We’ll cover everything you need to know to choose the right ink for your next project.

Choosing the right non woven bag screen printing ink can significantly impact the final look and feel of your custom bags. There are several factors to consider, including the type of non-woven fabric, desired print durability, and environmental impact. Let’s explore the key aspects of this specialized ink.

Understanding Non-Woven Fabrics and Ink Compatibility

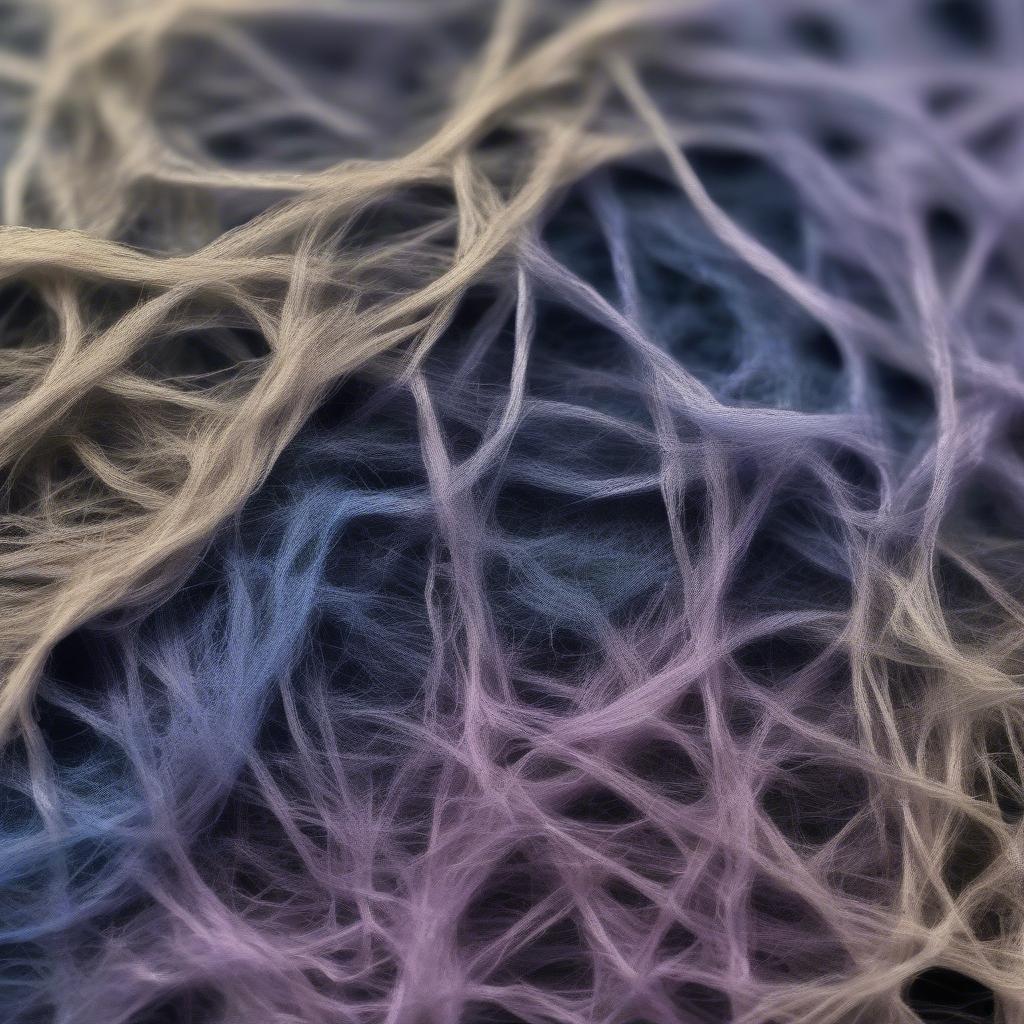

Non-woven fabrics are popular for their versatility and cost-effectiveness. They are made from bonded fibers, creating a durable yet lightweight material ideal for shopping bags, promotional items, and more. custom shopping bags non woven highlights the growing trend of personalized non-woven bags. Understanding the characteristics of these fabrics is key to selecting the appropriate ink.

Non-woven Fabric Microscopic View

Non-woven Fabric Microscopic View

Because non-woven materials are porous, they require inks that can adhere effectively without bleeding or soaking through. Plastisol inks are a common choice due to their thick consistency and excellent opacity. However, water-based and eco-friendly inks are gaining popularity as sustainability becomes a greater concern.

Types of Non Woven Bag Screen Printing Ink

Several ink formulations are specifically designed for non-woven fabrics. Each offers unique characteristics that cater to different project needs. Here’s a breakdown of the most common types:

- Plastisol Inks: Known for their vibrant colors and excellent opacity, plastisol inks are a popular choice for non-woven bags. They require heat curing, making them durable and long-lasting.

- Water-based Inks: These inks are environmentally friendly and offer a softer hand feel compared to plastisol inks. They are ideal for projects where a softer print is desired.

- UV Inks: UV inks cure instantly when exposed to ultraviolet light, making them a fast and efficient option. They offer excellent adhesion and durability.

Screen Printing Techniques for Non-Woven Bags

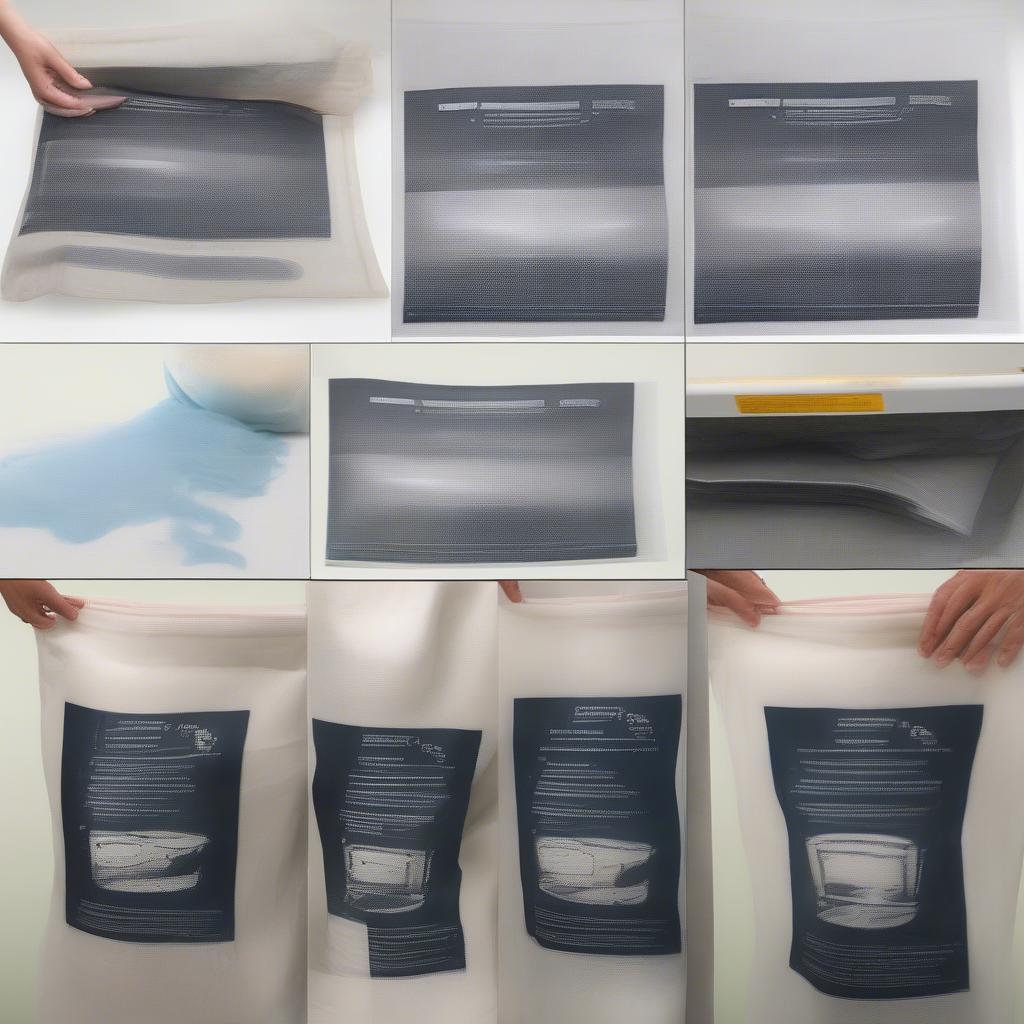

Achieving a professional finish requires proper screen printing techniques. Here’s a brief overview of the process:

- Prepare the Screen: Ensure your screen is properly coated and the design is accurately transferred.

- Ink Selection: Choose the right ink based on the fabric and desired outcome.

- Printing: Carefully apply the ink to the non-woven bag, ensuring even coverage.

- Curing: Cure the ink according to the manufacturer’s instructions. For plastisol inks, this involves heat; for UV inks, it involves UV light exposure.

Screen Printing Non-Woven Bag Process

Screen Printing Non-Woven Bag Process

“Proper screen preparation is vital for achieving a clean and sharp print on non-woven bags,” says renowned printing expert, John Miller. “A well-tensioned screen and properly exposed stencil are essential for preventing ink bleeding and ensuring design accuracy.”

Tips for Successful Non Woven Bag Screen Printing

Here are some expert tips to ensure your non-woven bag screen printing projects are successful:

- Test Your Ink: Always test your chosen ink on a scrap piece of non-woven fabric before printing on the final product. This will help you ensure color accuracy and prevent unexpected issues.

- Proper Screen Mesh: Select the appropriate screen mesh count based on the ink type and design complexity.

- Cure Temperature: Carefully monitor the curing temperature for plastisol inks to avoid scorching the fabric or under-curing the ink.

“The quality of the non woven bag screen printing ink directly affects the final product,” notes industry veteran, Sarah Johnson. “Investing in high-quality ink is essential for achieving vibrant colors and long-lasting prints.”

Finished Printed Non-Woven Bags

Finished Printed Non-Woven Bags

non woven bag print provides additional insights into the printing process.

Conclusion

Selecting the appropriate non woven bag screen printing ink is crucial for creating eye-catching and durable designs. By considering the fabric type, desired print characteristics, and environmental impact, you can choose the best ink for your project. With the right tools, techniques, and a little practice, you can achieve professional-looking results every time.

youtube woven bag printing machine offers a visual demonstration of the printing process. high quality professional oem non-woven gift shopping bag showcases examples of high-quality printed non-woven bags.

FAQ

- What is the best ink for printing on non-woven polypropylene bags?

- What are the different types of non-woven bag printing inks available?

- How do I cure plastisol ink on non-woven bags?

- What screen mesh count should I use for printing on non-woven bags?

- Are there eco-friendly ink options for non-woven bag printing?

- How do I prevent ink bleeding when screen printing on non-woven fabric?

- Where can I purchase high-quality non-woven bag screen printing ink?

Need assistance with your non-woven bag printing project? Contact our 24/7 customer support at +84 388 951 999 or visit us in Hanoi, Vietnam, or Tech Avenue, Suite 12, San Francisco, CA 94105, USA.