Weave Hat

Understanding the Hat Weaving Machine

Hat Weaving Machines are revolutionizing the millinery industry, offering efficiency and precision in crafting a wide variety of headwear. From classic fedoras to trendy beanies, understanding these machines unlocks a world of possibilities for both hobbyists and large-scale manufacturers. This article delves into the intricacies of hat weaving machines, exploring their types, functionalities, and impact on the art of hat making.  Close-up view of a modern hat weaving machine in operation, showcasing its intricate mechanisms and precision.

Close-up view of a modern hat weaving machine in operation, showcasing its intricate mechanisms and precision.

Different Types of Hat Weaving Machines

Several types of hat weaving machines cater to different needs and production scales. Circular knitting machines are commonly used for seamless beanies and other close-fitting hats. These machines use a series of needles arranged in a circle to create a continuous tube of knitted fabric. crochet-basket-weave-hats Flat knitting machines, on the other hand, produce flat pieces of fabric that are then shaped and sewn into hats. These machines offer greater design flexibility, allowing for intricate patterns and textures. Finally, specialized hat blocking machines are used to give hats their final shape and form.

Exploring the Mechanics of a Hat Weaving Machine

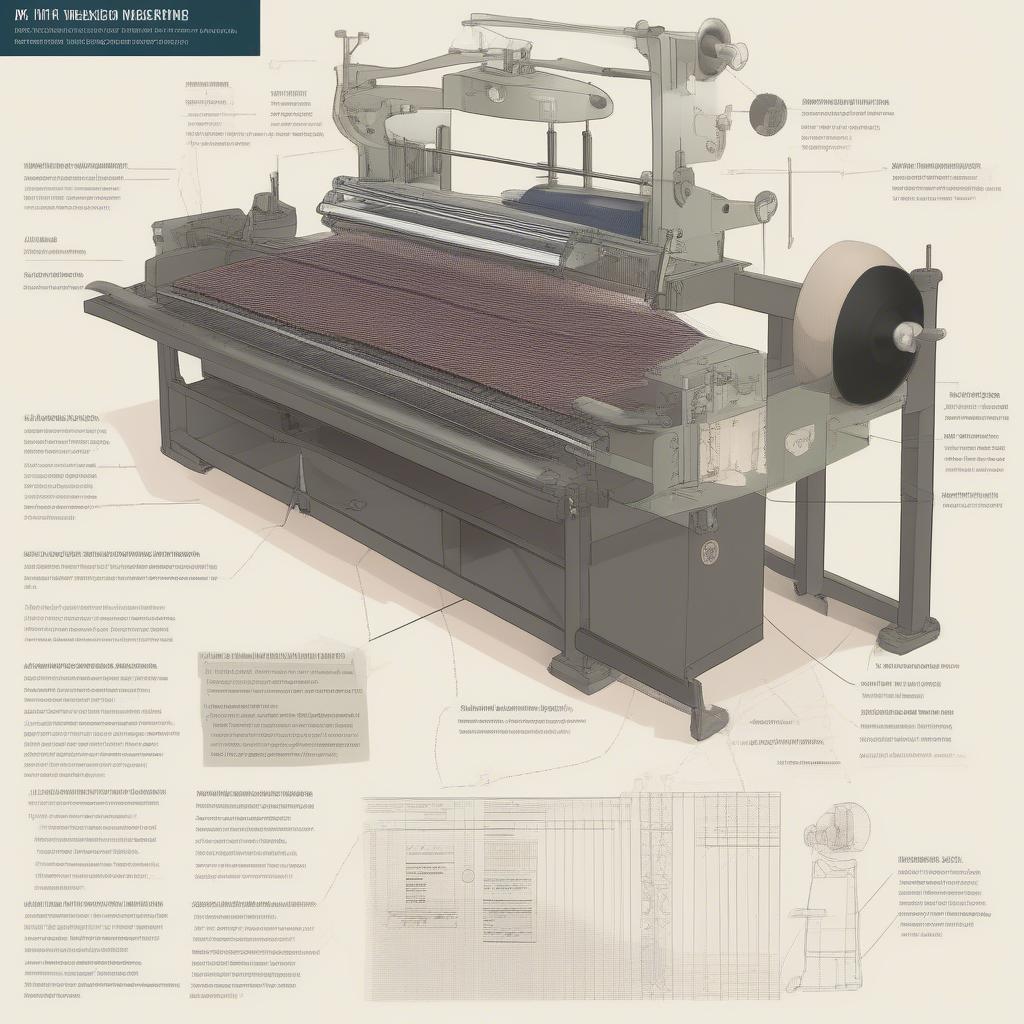

Regardless of the type, hat weaving machines operate on the principle of interlacing yarns to create a fabric structure. This process involves a complex interplay of needles, yarn carriers, and control mechanisms.  Detailed view of the key components of a hat weaving machine, including needles, yarn carriers, and control panel. The needles catch and hold the yarn, while the carriers move the yarn across the needles to create the desired weave pattern. The entire process is controlled by a computerized system that allows for precise adjustments to the stitch patterns and hat dimensions.

Detailed view of the key components of a hat weaving machine, including needles, yarn carriers, and control panel. The needles catch and hold the yarn, while the carriers move the yarn across the needles to create the desired weave pattern. The entire process is controlled by a computerized system that allows for precise adjustments to the stitch patterns and hat dimensions.

The Impact of Hat Weaving Machines on the Millinery Industry

Hat weaving machines have significantly impacted the millinery industry, increasing production speed and consistency. What once took hours of meticulous handwork can now be achieved in minutes. ballistic-weave-hats-list This has not only made hats more accessible but has also opened up new avenues for creativity and design. Manufacturers can now produce complex and intricate hat designs that were previously impossible to achieve by hand.

How Hat Weaving Machines Enhance Design Possibilities

The precision and control offered by hat weaving machines enable designers to experiment with a wide range of yarns, textures, and patterns. From delicate lace to chunky cable knits, the possibilities are endless. Furthermore, these machines allow for the incorporation of embellishments and other decorative elements directly into the weaving process. coconut-palm-leaf-weaved-sun-hats This level of customization has transformed hat making from a traditional craft into a modern art form.

What are the benefits of using a hat weaving machine?

Using a hat weaving machine offers several benefits, including increased speed and efficiency, consistent quality, and greater design flexibility. These machines can produce hats much faster than hand-weaving, allowing for higher production volumes. They also ensure consistent quality, eliminating the variations that can occur with hand-made products. captain-weaver-hat

How do I choose the right hat weaving machine?

Choosing the right hat weaving machine depends on several factors, including your production needs, budget, and desired hat styles. Smaller, manual machines are suitable for hobbyists and small businesses, while larger, automated machines are better suited for large-scale production. china-hat-weaving-machine Consider the types of hats you want to create and the materials you’ll be working with when making your decision.  Various types of hat weaving machines, showcasing different sizes and functionalities.

Various types of hat weaving machines, showcasing different sizes and functionalities.

“The advent of hat weaving machines has been a game-changer for our industry,” says Amelia Milliner, a renowned hat designer. “It allows us to push the boundaries of creativity and bring our most intricate visions to life.” Another expert, Henry Hatter, a veteran hat maker, adds, “These machines have not only increased our efficiency but also allowed us to maintain the highest standards of quality.” A third expert, Sophie Weaver, a textile engineer specializing in hat making machinery, notes, “The future of hat making lies in the continuous innovation of these machines, enabling even more complex and personalized designs.”

In conclusion, the hat weaving machine has revolutionized the art of hat making. From increasing production efficiency to expanding design possibilities, this technology has transformed the millinery landscape. Whether you’re a seasoned milliner or a passionate hobbyist, understanding the capabilities of the hat weaving machine is essential for navigating the ever-evolving world of headwear.

FAQ:

- What types of hats can be made with a hat weaving machine?

- How does a hat weaving machine work?

- What are the benefits of using a hat weaving machine?

- How do I choose the right hat weaving machine?

- What are the maintenance requirements for a hat weaving machine?

- Where can I buy a hat weaving machine?

- Are there online resources for learning how to use a hat weaving machine?

For further information, explore our other articles on china hat weaving machine and coconut palm leaf weaved sun hats.

Need help? Contact our 24/7 customer service at +84 388 951 999 or visit us at Hanoi, Vietnam, or Tech Avenue, Suite 12, San Francisco, CA 94105, USA.