Woven Bag

PP Cement Woven Bags: A Comprehensive Guide

Pp Cement Woven Bags are a ubiquitous sight in the construction industry, known for their strength, durability, and affordability. These bags are essential for transporting and storing cement, but their versatility extends beyond construction. Let’s explore the world of pp cement woven bags, from manufacturing to applications, covering everything you need to know. loewe vogue ad woven bag

What are PP Cement Woven Bags?

PP cement woven bags are made from woven polypropylene fabric, a thermoplastic polymer known for its resistance to tearing, chemicals, and moisture. This makes them ideal for packaging materials like cement, which requires protection from the elements. The weaving process creates a strong, flexible material that can withstand the weight and pressure of heavy contents.

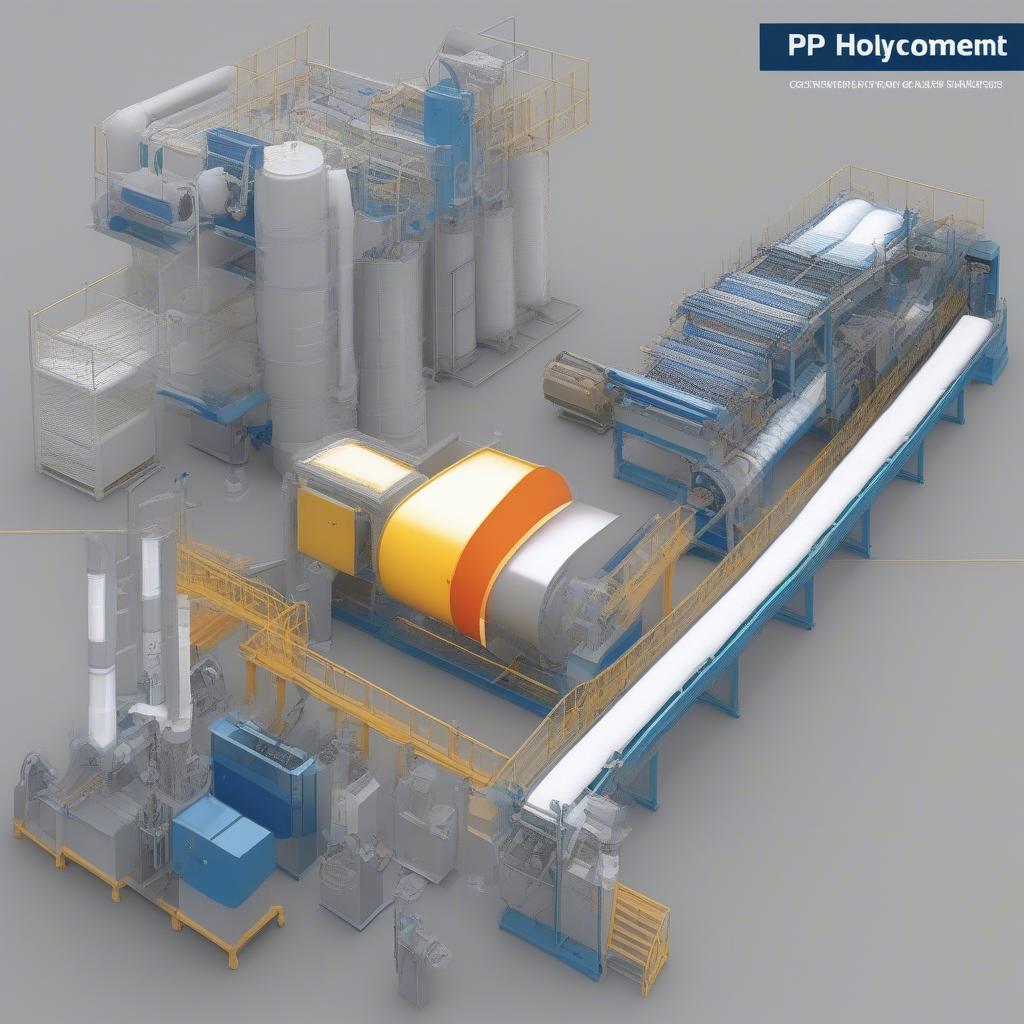

PP Cement Woven Bags Manufacturing Process

PP Cement Woven Bags Manufacturing Process

Why Choose PP Cement Woven Bags?

Several factors contribute to the popularity of pp cement woven bags. Their inherent strength and resistance to damage are paramount, especially for a product like cement. Cost-effectiveness also plays a major role, making them a preferred choice over other packaging options. Furthermore, the bags are lightweight, simplifying handling and transportation. They are also reusable and recyclable, contributing to sustainable practices. plastic woven sand bags,

Advantages of PP Cement Woven Bags

- Strength and Durability: The woven structure provides excellent resistance to tearing and bursting.

- Moisture Resistance: Polypropylene is inherently water-resistant, protecting the cement from moisture damage.

- Cost-Effective: PP woven bags offer a budget-friendly packaging solution.

- Lightweight: Easy handling and reduced transportation costs.

- Reusable and Recyclable: Contributes to environmental sustainability.

The Manufacturing Process of PP Cement Woven Bags

The production of pp cement woven bags involves a series of steps, from raw material processing to the final product. It starts with polypropylene granules, which are melted and extruded into thin tapes. These tapes are then woven into fabric using specialized looms. The woven fabric is then cut and sewn into bags, often with added features like handles or liners. Finally, the bags are printed with relevant information, such as manufacturer details and product specifications.

Different Types of PP Cement Woven Bags

Different Types of PP Cement Woven Bags

“The manufacturing process is constantly evolving with advancements in technology, leading to improved efficiency and quality,” says John Miller, a packaging engineer with over 20 years of experience.

Different Types of PP Cement Woven Bags

There are various types of pp cement woven bags available to cater to different needs. They come in different sizes, colors, and designs. Some common variations include:

- Standard PP Woven Bags: These are the most common type, used for general cement packaging.

- Laminated PP Woven Bags: An additional layer of film enhances moisture protection.

- BOPP Laminated PP Woven Bags: BOPP (Biaxially Oriented Polypropylene) lamination offers superior printing and aesthetics.

- Gusseted PP Woven Bags: Side gussets allow for increased capacity and stability.

Beyond Cement: Other Applications of PP Woven Bags

While primarily associated with cement, pp cement woven bags find applications in other industries as well. They are used for packaging various products, including:

- Fertilizers: Similar to cement, fertilizers benefit from the protective qualities of PP woven bags.

- Animal Feed: The durability of the bags is crucial for storing and transporting animal feed.

- Grains and Seeds: Protection from moisture and pests is essential for agricultural products.

- Chemicals: The chemical resistance of polypropylene makes these bags suitable for certain chemicals.

are non woven polypropylene bags manually sewn

PP Woven Bags Used for Different Applications

PP Woven Bags Used for Different Applications

“The versatility of PP woven bags is remarkable. They are a sustainable and cost-effective solution for a wide range of industries,” adds Maria Garcia, a sustainability consultant specializing in packaging solutions.

Choosing the Right PP Cement Woven Bags

Selecting the appropriate pp cement woven bags requires considering several factors. The weight and volume of the contents are crucial in determining the size and strength of the bag. Environmental conditions, such as exposure to moisture or sunlight, should also be considered. Printing requirements, like branding and product information, also play a role in the selection process.

Conclusion

PP cement woven bags are a versatile and essential packaging solution, primarily in the construction industry but also across various other sectors. Their strength, durability, and cost-effectiveness make them a popular choice for storing and transporting a range of materials. Understanding the different types available and their specific applications is crucial for making informed purchasing decisions. used non woven bag making machine price list By choosing the right pp cement woven bags, businesses can ensure the safe and efficient handling of their products. china giveaway non woven bag quotes

FAQ

- What are the benefits of using pp cement woven bags?

- How are pp cement woven bags manufactured?

- What are the different types of pp cement woven bags available?

- What are the other applications of pp cement woven bags besides cement?

- What factors should be considered when choosing pp cement woven bags?

- Are pp cement woven bags recyclable?

- What are the typical sizes of pp cement woven bags?

When you need assistance, please contact our Hotline: +84 388 951 999, our address in Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.