Woven Bag

Sand Plastic Used Bopp PP Woven Bag: A Comprehensive Guide

Sand Plastic Used Bopp Pp Woven Bags are a common sight in construction and industrial settings. But what exactly are they, and how are they made? This guide delves into the world of these versatile bags, exploring their composition, manufacturing process, benefits, and various applications.

Sand Plastic Used Bopp PP Woven Bag Manufacturing Process

Sand Plastic Used Bopp PP Woven Bag Manufacturing Process

Understanding Sand Plastic Used Bopp PP Woven Bags

These bags are primarily made from woven polypropylene (PP) fabric, a thermoplastic polymer known for its strength, durability, and resistance to moisture, chemicals, and UV rays. The term “sand plastic” often refers to recycled plastic or plastic granules that might be mixed with virgin PP to create the woven fabric. The Bopp film lamination provides added protection against moisture and enhances the bag’s printability, making it ideal for branding and labeling. They offer a robust and cost-effective solution for packaging and transporting various materials, especially sand, cement, fertilizers, and other construction aggregates.

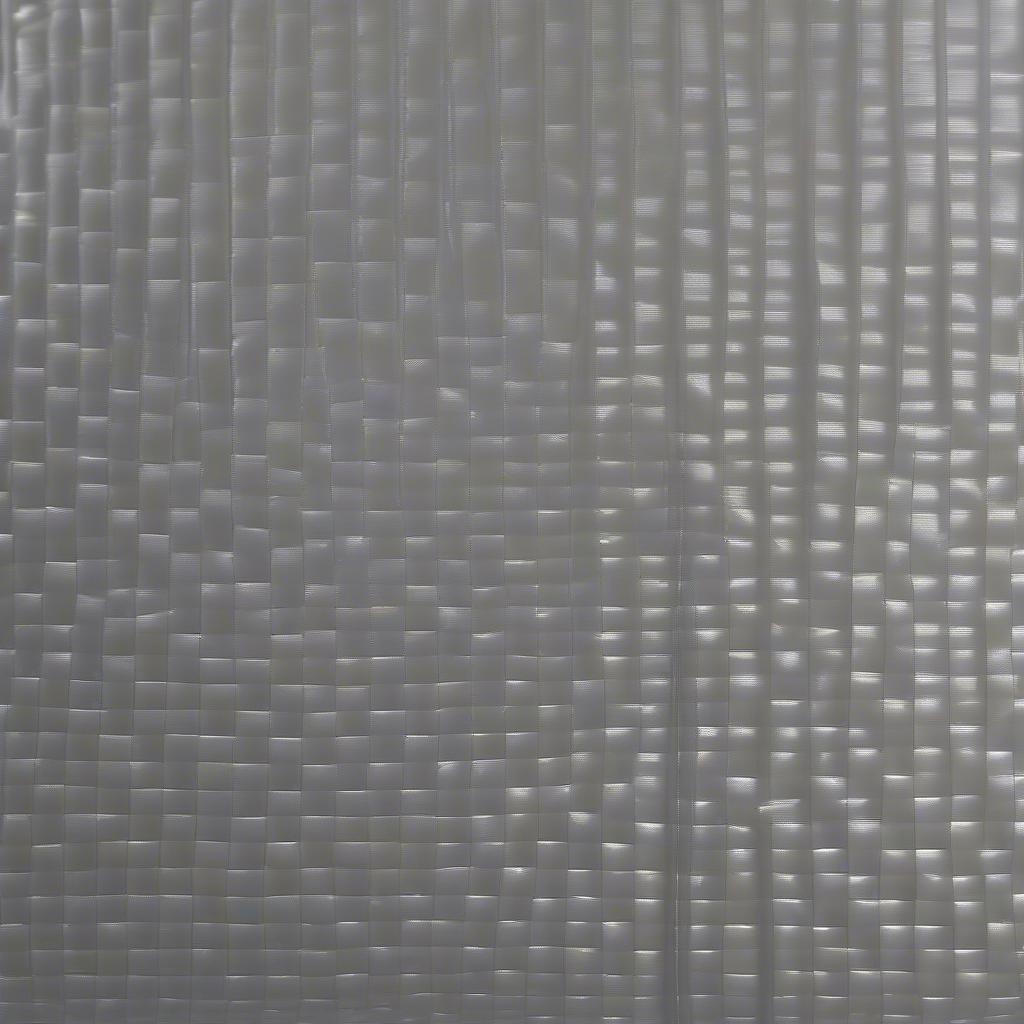

Close-up view of Bopp PP Woven Bag Texture

Close-up view of Bopp PP Woven Bag Texture

Benefits of Using Sand Plastic Used Bopp PP Woven Bags

- Strength and Durability: Woven polypropylene offers excellent tensile strength, making these bags resistant to tearing and punctures. This is crucial for handling heavy materials like sand and gravel.

- Moisture Resistance: The Bopp film lamination acts as a barrier against moisture, protecting the contents from dampness and rain.

- UV Protection: PP woven bags are inherently UV resistant, which prevents degradation from prolonged sun exposure, ensuring the bag’s longevity.

- Cost-Effectiveness: Compared to other packaging options, these bags offer a cost-effective solution, especially for bulk materials.

- Recyclability: Polypropylene is a recyclable material, contributing to a more sustainable packaging solution. You can find similar products such as pp woven sack bags on our website.

Manufacturing Process of Sand Plastic Used Bopp PP Woven Bags

The production process involves several key stages:

- Raw Material Preparation: This involves sourcing and processing the polypropylene resin, often incorporating recycled plastic or granules.

- Extrusion: The resin is melted and extruded into thin tapes.

- Weaving: These tapes are then woven into the desired fabric structure using specialized looms.

- Cutting and Sewing: The woven fabric is cut and sewn into the bag shape.

- Bopp Lamination (Optional): A layer of Bopp film is applied for added protection and printability. hdpe woven fabric bag are another alternative.

Various Sizes of Sand Plastic Bopp PP Woven Bags

Various Sizes of Sand Plastic Bopp PP Woven Bags

Applications of Sand Plastic Used Bopp PP Woven Bags

These bags are widely used in:

- Construction: For packaging and transporting sand, cement, gravel, and other construction materials.

- Agriculture: For storing and transporting fertilizers, seeds, and agricultural produce.

- Industrial Packaging: For packaging chemicals, resins, and other industrial products. We also offer plastic woven bags wholesale.

What are the common sizes of these bags?

Common sizes range from 25kg to 1000kg capacity, depending on the application.

Can these bags be customized?

Yes, they can be customized with printing, labeling, and different colors. woven bopp bags offer great customization options.

“The use of recycled plastic in these bags is a significant step towards sustainable packaging,” says Dr. Maria Sanchez, a leading materials scientist.

“Bopp lamination provides crucial protection against moisture and enhances the bag’s shelf life,” adds John Davis, a packaging engineer with 20 years of experience. Check out our woven polypropylene bulk bags.

Conclusion

Sand plastic used bopp pp woven bags provide a durable, cost-effective, and versatile packaging solution for various industries. Their strength, moisture resistance, and recyclability make them a popular choice for transporting and storing bulk materials.

FAQs

- What is the lifespan of a typical sand plastic used bopp pp woven bag?

- How much weight can these bags typically hold?

- Are these bags resistant to chemicals?

- Can these bags be reused?

- What are the environmental benefits of using these bags?

- How are these bags disposed of?

- What are the alternatives to these bags?

Need help? Contact our hotline: +84 388 951 999 or visit us in Hanoi, Vietnam, or at Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We offer 24/7 customer support.