Woven Bag

Essential Parts for a PP Woven Bag Machine

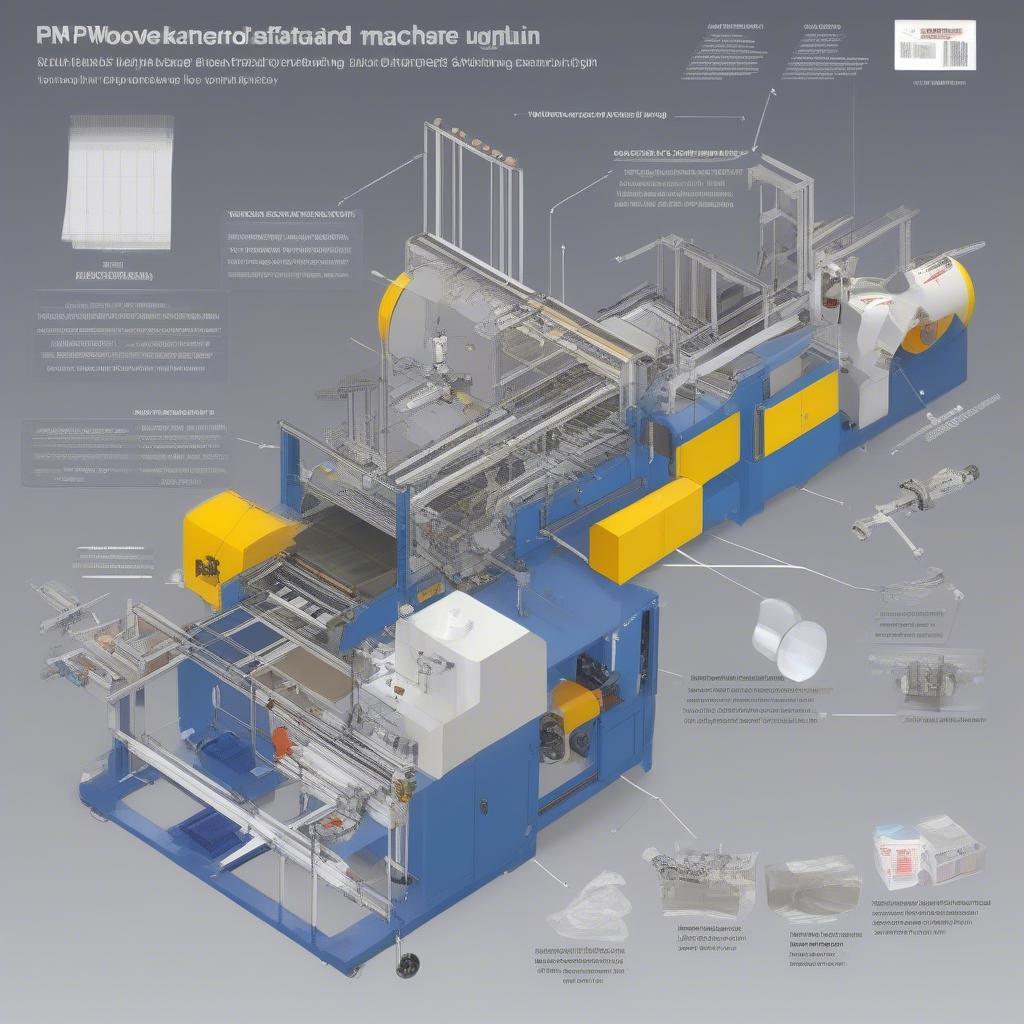

Understanding the key parts of a pp woven bag machine is crucial for efficient production and maintaining the longevity of your equipment. Whether you’re a seasoned manufacturer or just starting out, this guide will provide valuable insights into the essential components that drive these powerful machines.  PP Woven Bag Machine Components Diagram

PP Woven Bag Machine Components Diagram

Key Components of a PP Woven Bag Making Machine

PP woven bag machines are complex systems comprised of several interconnected parts, each playing a vital role in transforming polypropylene granules into finished bags. Let’s delve into some of the most important components:

- Extruder: This is the heart of the machine, responsible for melting and extruding the polypropylene granules into a continuous sheet or film. The extruder’s temperature and pressure settings are critical for achieving the desired material properties.

- Cutting Unit: Precision cutting is essential for creating consistently sized bags. This unit works in tandem with the extruder, cutting the extruded film into the required width and length for bag formation.

- Printing Unit: For branded bags or those requiring specific markings, the printing unit applies designs and logos onto the woven fabric. Modern machines offer various printing options, including flexographic and rotogravure printing.

- Stitching Unit: This component stitches the cut fabric pieces together to form the final bag shape. The stitching unit’s settings determine the strength and durability of the bag seams.

- Winder/Rewinder: This component manages the woven fabric roll, ensuring consistent tension and smooth operation during the bag-making process.

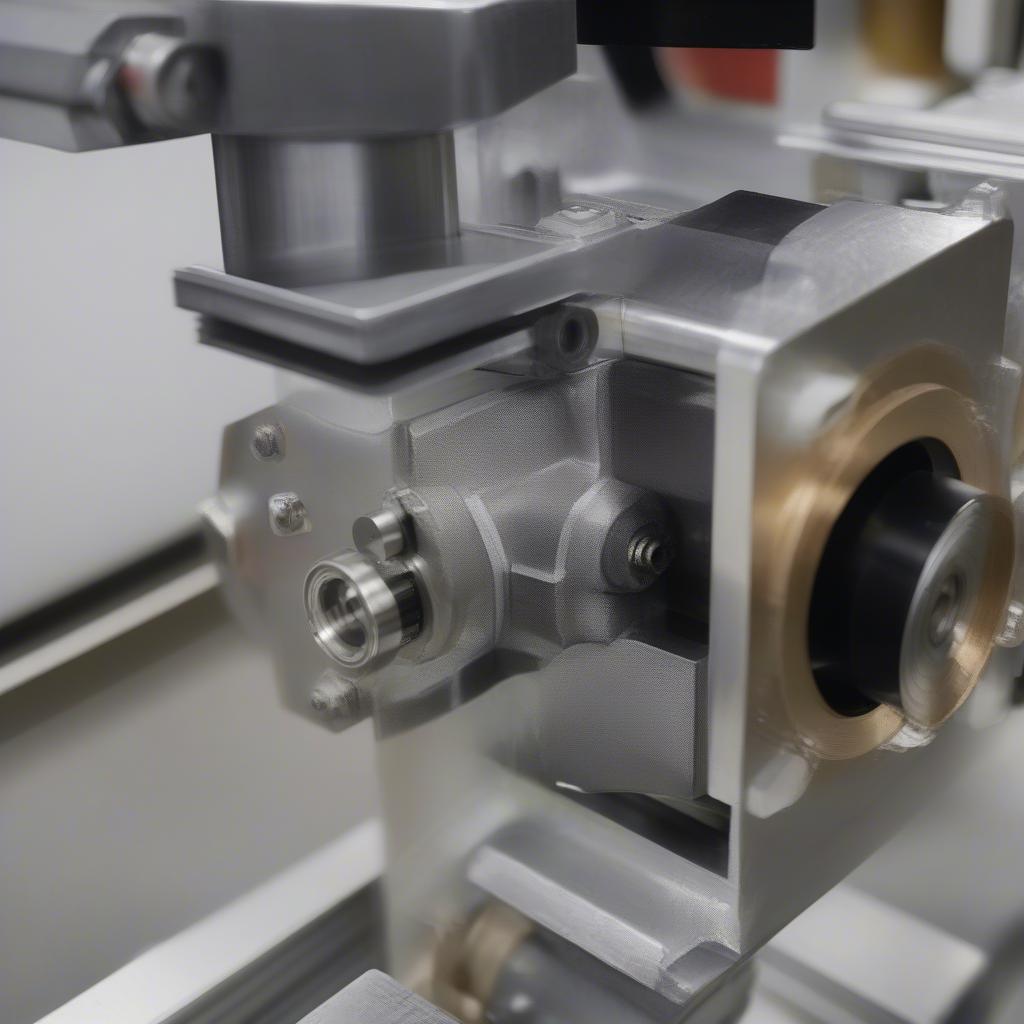

Close-up View of the Extruder Unit in a PP Woven Bag Machine

Close-up View of the Extruder Unit in a PP Woven Bag Machine

Maintaining Your PP Woven Bag Machine: Focusing on Key Parts

Regular maintenance is paramount for optimal performance and preventing costly breakdowns. Here’s a look at maintaining key parts for your pp woven bag machine:

- Regular cleaning of the extruder: Buildup of residual polypropylene can affect the extruder’s efficiency and lead to inconsistent extrusion. Regular cleaning prevents these issues and ensures consistent product quality.

- Inspecting and lubricating the cutting unit: Sharp blades are crucial for clean cuts. Regular inspection and lubrication of the cutting unit prevent wear and tear, ensuring precise cutting and reducing waste.

- Maintaining the printing unit: Clean printing rollers and proper ink management are essential for clear and vibrant prints. Regular maintenance prevents ink smudging and ensures consistent print quality.

You can find suppliers for these essential parts through various online platforms or directly from manufacturers. Sourcing quality parts is essential for maintaining the efficiency and longevity of your machine. Remember, proper maintenance of your non woven bag making machine supplier can significantly impact its lifespan and productivity.

Troubleshooting Common Issues with Parts for PP Woven Bag Machine

- Inconsistent extrusion: This issue could be caused by clogged extruders, incorrect temperature settings, or worn-out extruder components.

- Uneven cutting: Dull blades, misaligned cutting units, or issues with the winder/rewinder can lead to uneven cutting.

- Poor print quality: This could be due to clogged printing rollers, incorrect ink viscosity, or issues with the printing unit’s settings.

Technician Performing Maintenance on a PP Woven Bag Machine

Technician Performing Maintenance on a PP Woven Bag Machine

For those looking for alternative bag-making solutions, consider exploring mini non woven bag making machine. These compact machines are ideal for smaller-scale operations.

Conclusion

Understanding the Parts For Pp Woven Bag Machine is fundamental for efficient and profitable bag production. By focusing on regular maintenance and troubleshooting common issues, you can maximize your machine’s lifespan and ensure consistent output. Investing in high-quality parts and understanding their function is crucial for success in the woven bag industry. Consider the woven plastic bags embroidered sunrise as a beautiful example of what these machines can create.

FAQ

- What are the main parts of a PP woven bag machine?

- How often should I perform maintenance on my PP woven bag machine?

- Where can I find reliable suppliers for parts for pp woven bag machine?

- What are some common issues with the extruder unit?

- How can I improve the print quality of my bags?

- What are some tips for maintaining the cutting unit?

- Where can I find information on non woven loop handle bag making machine manufacturers?

Common Scenarios & Questions

- Scenario: My extruder is producing inconsistent film. Question: What are the possible causes and solutions?

- Scenario: The cutting unit is making uneven cuts. Question: What parts should I inspect and how can I fix this issue?

- Scenario: The print quality on my bags is poor. Question: What maintenance steps can I take to improve the print quality?

Further Exploration

You may also be interested in learning about woven sack bag stitching machine for more specialized bag production.

Need assistance? Contact our 24/7 customer support hotline: +84 388 951 999. We’re located in Hanoi, Vietnam and Tech Avenue, Suite 12, San Francisco, CA 94105, USA.