Woven Bag

Non Woven Roll for Bags: A Comprehensive Guide

Non woven roll material is a popular choice for bag manufacturing, offering a blend of durability, affordability, and versatility. From shopping totes to reusable grocery bags, non woven fabric has revolutionized the bag industry. This guide dives deep into the world of non woven rolls, exploring their benefits, applications, and the factors to consider when choosing the right one for your bag project.

Understanding Non Woven Fabric

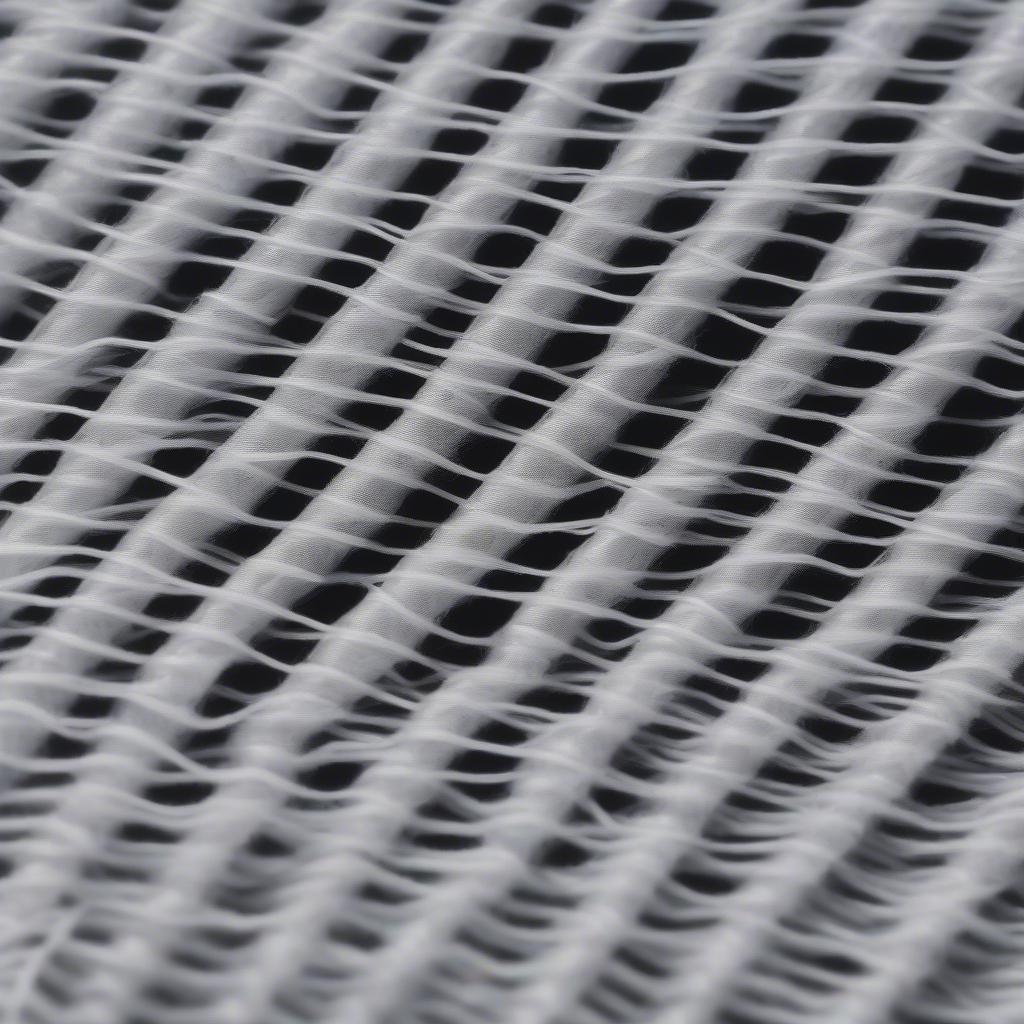

Non woven fabrics are engineered materials created by bonding fibers together without weaving or knitting. This process results in a strong, lightweight material that’s ideal for a variety of applications, including bag making. Unlike traditional woven fabrics, non woven materials are made directly from fibers, offering unique advantages in terms of cost and production speed. They’re also incredibly versatile, available in various thicknesses, colors, and textures, making them perfect for creating diverse bag styles.  Non Woven Fabric Structure: A microscopic view of bonded fibers

Non Woven Fabric Structure: A microscopic view of bonded fibers

Benefits of Using Non Woven Roll for Bags

Non woven rolls offer several key benefits for bag production:

- Durability: Non woven bags are tear-resistant and can withstand considerable weight.

- Cost-effectiveness: Compared to traditional fabrics, non woven rolls are generally less expensive.

- Versatility: They can be easily customized with prints, colors, and finishes.

- Eco-friendliness: Many non woven materials are recyclable, making them a sustainable choice.

- Breathability: This characteristic makes them suitable for carrying fresh produce.

These advantages have contributed to the increasing popularity of non woven bags manufacturing machine factory.

Choosing the Right Non Woven Roll

Selecting the right non woven roll depends on several factors, including the intended use of the bag, desired aesthetics, and budget. Consider these key aspects:

- GSM (Grams per Square Meter): This measurement indicates the fabric’s weight and thickness. Higher GSM typically means a stronger and more durable bag.

- Width: Choose the roll width according to your bag dimensions to minimize waste.

- Color and Finish: Non woven rolls are available in a wide range of colors and finishes, allowing for customization to match your brand or project requirements.

- Material Composition: Different fiber blends offer varying properties, such as water resistance or breathability. Consider polypropylene (PP) or spunbond non woven options.

Selecting the right non woven roll

Selecting the right non woven roll

“Choosing the right GSM is crucial for bag durability,” says Sarah Miller, a leading expert in sustainable packaging. “A higher GSM is ideal for heavy-duty bags like sand bag non woven geotextile, while a lower GSM might suffice for lighter shopping bags.”

Applications of Non Woven Bags

Non woven bags have a wide range of applications, including:

- Shopping bags: Reusable shopping bags are a sustainable alternative to plastic bags.

- Promotional bags: Custom printed non woven bags are effective marketing tools.

- Grocery bags: Durable and breathable, they are perfect for carrying groceries.

- Gift bags: Add a personal touch with customized non woven gift bags.

- Trade show bags: Distribute promotional materials and giveaways in branded non woven bags.

Non Woven Bags vs. Woven Bags: A Comparison

While both types serve the purpose of carrying items, they have distinct differences. Non woven bags are typically more cost-effective and easier to produce, while woven bags, like the green woven bag, often offer a more premium look and feel. The choice between the two depends on factors like budget, desired aesthetic, and intended use. audrey hepburn woven bag illustrates the elegant style that woven bags can achieve.

Comparison of Woven and Non-woven Bags

Comparison of Woven and Non-woven Bags

“Non woven bags have become increasingly popular due to their versatility and affordability,” adds John Davis, a veteran bag manufacturer. “Their adaptability to various printing techniques makes them ideal for promotional and branding purposes.”

Conclusion

Non Woven Roll For Bags offers a versatile and cost-effective solution for a wide range of applications. Understanding the different types of non woven materials, their properties, and the factors influencing their suitability for specific bag projects is crucial for making informed decisions. Choosing the right non woven roll ensures that the resulting bags are durable, functional, and aesthetically pleasing, meeting the diverse needs of consumers and businesses alike.

FAQ

- What is the typical lifespan of a non woven bag?

- Can non woven bags be recycled?

- What are the different printing methods for non woven bags?

- How do I choose the right GSM for my non woven bag?

- What is the difference between spunbond and meltblown non woven fabrics?

- Are non woven bags waterproof?

- What are the environmental benefits of using non woven bags?

For further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team available to answer your questions.