Woven Bag

Non Woven Bag Welding Machine: A Comprehensive Guide

Non Woven Bag Welding Machines are essential for producing high-quality, durable non-woven bags. These machines use various technologies, including ultrasonic welding, to fuse fabric pieces together, creating strong and reliable seams. Understanding the different types, features, and benefits of these machines is crucial for businesses involved in the non-woven bag industry. ultrasonic non woven bag welding machine

Types of Non Woven Bag Welding Machines

There are several types of non woven bag welding machines available, each designed for specific applications and production volumes. Some popular types include ultrasonic welding machines, heat sealing machines, and sewing machines. Ultrasonic welding is a preferred method due to its speed, precision, and clean finish. Heat sealing, while effective, can sometimes result in less aesthetically pleasing seams. Traditional sewing, although slower, offers versatility for complex bag designs. Choosing the right machine depends on factors like bag size, material thickness, and desired production speed.

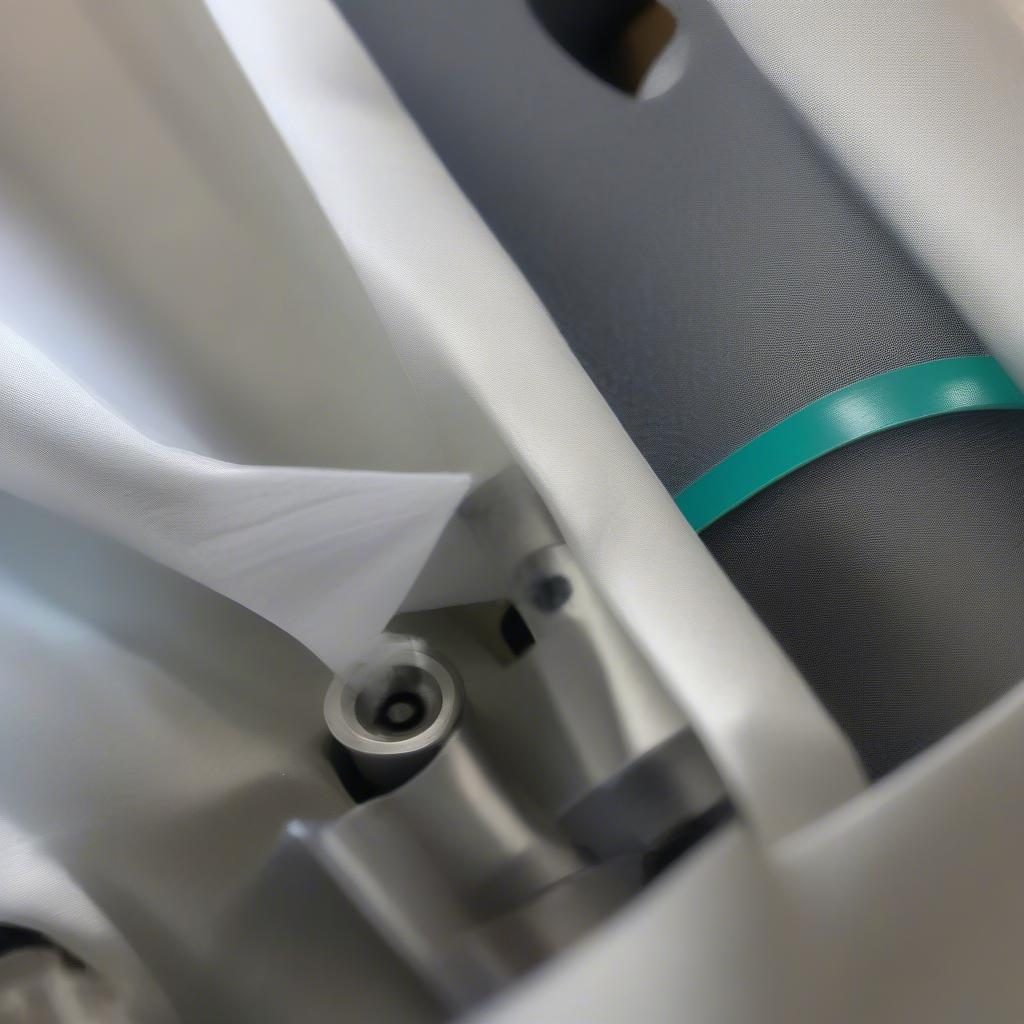

Ultrasonic Non Woven Bag Welding Machines

Ultrasonic welding machines use high-frequency vibrations to melt and fuse the non-woven fabric. This creates strong, clean seams without the need for needles or thread. These machines are ideal for high-volume production and offer consistent results.

Ultrasonic Non Woven Bag Welding Machine in Action

Ultrasonic Non Woven Bag Welding Machine in Action

Heat Sealing Machines for Non Woven Bags

Heat sealing machines use heat and pressure to bond the fabric together. While cost-effective, they can sometimes create less aesthetically pleasing seams compared to ultrasonic welding.

Sewing Machines for Non Woven Bag Production

Traditional sewing machines are also used for non-woven bag production, particularly for more complex bag designs or smaller production runs. Though slower, sewing allows for intricate stitching and customization.

Key Features and Benefits of Non Woven Bag Welding Machines

Non woven bag welding machines offer several key features and benefits:

- Speed and Efficiency: Automated machines significantly increase production speed compared to manual methods.

- Consistent Quality: They ensure consistent seam quality and strength throughout the production process.

- Versatility: Many machines can handle various bag sizes and material thicknesses.

- Cost-Effectiveness: Automated welding reduces labor costs and material waste.

- Durability: Welded seams are strong and durable, enhancing the lifespan of the bags.

non woven bag handle welding machine

Choosing the Right Non Woven Bag Welding Machine

Selecting the appropriate non woven bag welding machine depends on several factors:

- Production Volume: High-volume production requires automated, high-speed machines like ultrasonic welders.

- Bag Size and Design: Consider the dimensions and complexity of the bag design.

- Material Thickness: Different machines are designed for different material thicknesses.

- Budget: Machines vary in price, so it’s essential to consider your budget.

Factors to Consider When Choosing a Non Woven Bag Welding Machine

Factors to Consider When Choosing a Non Woven Bag Welding Machine

“The key to efficient non-woven bag production is selecting the right welding machine for your specific needs,” says Amelia Hernandez, a leading expert in industrial textile manufacturing. “Consider factors like production volume and bag design when making your decision.”

Maintaining Your Non Woven Bag Welding Machine

Regular maintenance is crucial for maximizing the lifespan and performance of your machine:

- Clean the machine regularly: Remove dust and debris to prevent malfunctions.

- Lubricate moving parts: Proper lubrication ensures smooth operation.

- Schedule professional inspections: Periodic inspections can identify potential issues before they become major problems.

non woven bag making machine manual factory

“Preventative maintenance is essential,” adds Dr. Michael Chen, a renowned mechanical engineer specializing in industrial machinery. “Regular cleaning and lubrication can significantly extend the life of your non woven bag welding machine.”

Maintaining Your Non Woven Bag Welding Machine

Maintaining Your Non Woven Bag Welding Machine

non woven bags manufacturing process

Conclusion

Investing in a high-quality non woven bag welding machine is essential for businesses in the non-woven bag industry. By understanding the different types of machines available, their key features, and maintenance requirements, you can optimize your production process and create durable, high-quality bags. Choosing the right non woven bag welding machine ultimately contributes to a successful and profitable business.

china non woven fabric bag making machine

When you need assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.