Woven Bag

Tubular PP Woven Gusseted Bag: A Comprehensive Guide

Tubular Pp Woven Gusseted Bags are a popular choice for various packaging needs, thanks to their durability and versatility. This guide delves into the intricacies of these bags, exploring their manufacturing process, benefits, applications, and more. We’ll unpack everything you need to know about tubular PP woven gusseted bags, from their construction to their environmental impact.

Understanding Tubular PP Woven Gusseted Bags

These bags are constructed from woven polypropylene fabric, a strong and lightweight material. The “gusseted” feature refers to the folds on the sides of the bag, which allow it to expand and hold more volume. This makes them ideal for packaging bulkier items. The tubular construction refers to the seamless cylindrical shape of the bag before the bottom is sealed. These bags offer a cost-effective and efficient packaging solution for various industries. Check out our resources on woven poly bags.

What Makes These Bags Unique?

Tubular PP woven gusseted bags stand out due to several key features:

- Strength and Durability: Woven polypropylene fabric is resistant to tearing, punctures, and abrasion, making it ideal for heavy-duty applications.

- Flexibility: The gusseted sides allow the bag to expand and accommodate various shapes and sizes of contents.

- Lightweight: Despite their strength, these bags are lightweight, reducing shipping costs.

- Customizability: They can be easily customized with printing, lamination, and other features to meet specific branding and functional requirements.

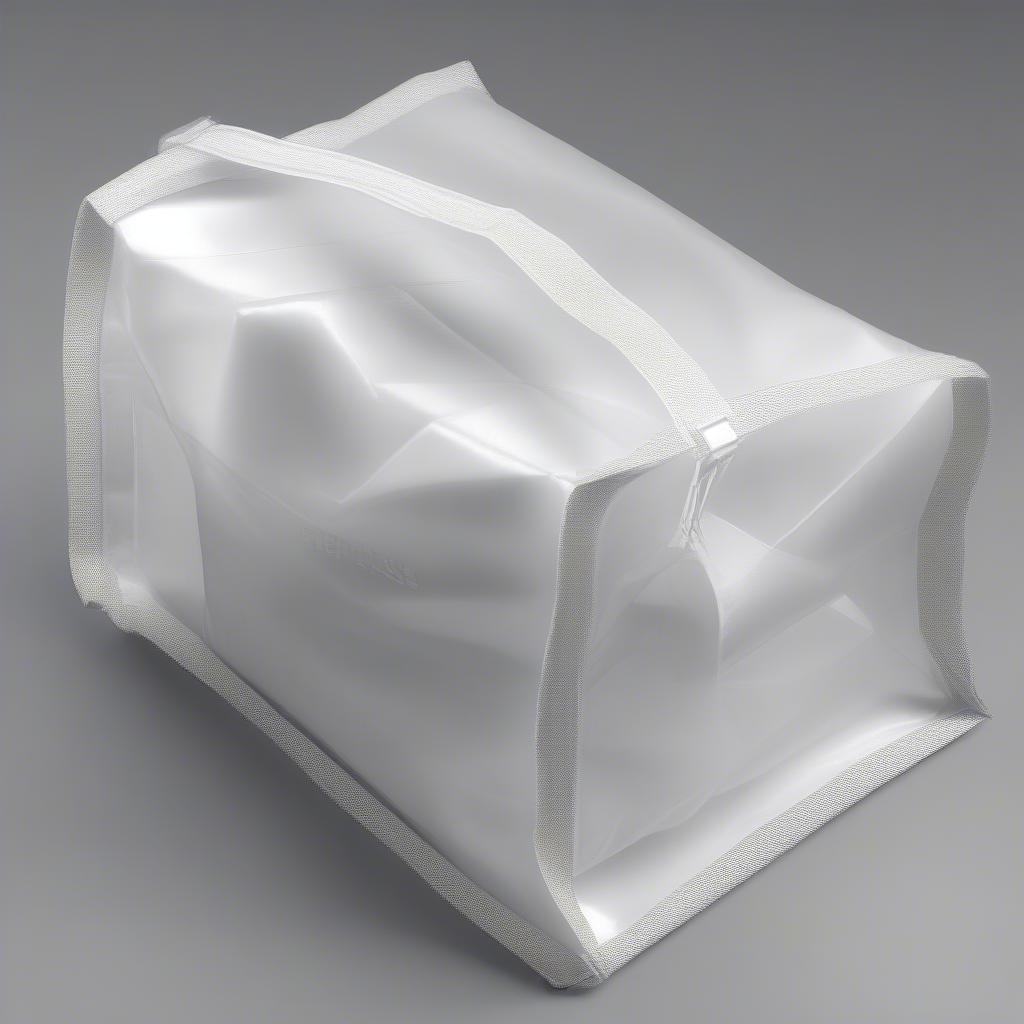

Tubular PP Woven Gusseted Bag Structure

Tubular PP Woven Gusseted Bag Structure

Advantages of Using Tubular PP Woven Gusseted Bags

These bags offer a number of advantages over other packaging options:

- Cost-Effective: They are generally less expensive than other packaging materials, such as paper or cardboard.

- Reusable: Many tubular PP woven gusseted bags are designed for multiple uses, reducing waste.

- Moisture Resistant: Polypropylene is inherently moisture resistant, protecting contents from damage.

- UV Resistant: Options are available with UV protection, safeguarding contents from sun damage.

“Tubular PP woven gusseted bags are the workhorse of the packaging industry,” says John Miller, Senior Packaging Engineer at PackTech Solutions. “Their versatility and durability make them a go-to choice for a wide range of products.”

Applications of Tubular PP Woven Gusseted Bags

From agricultural products to construction materials, these bags are used across various industries:

- Agriculture: Packaging grains, fertilizers, seeds, and animal feed.

- Construction: Holding sand, gravel, cement, and other building materials.

- Retail: Packaging clothing, toys, and other consumer goods.

- Food: Packaging dry food products like flour, sugar, and rice. Learn more about other options like tubular pp woven pe liner bag.

Tubular PP Woven Gusseted Bag Applications

Tubular PP Woven Gusseted Bag Applications

Manufacturing Process of Tubular PP Woven Gusseted Bags

The production process involves several key steps:

- Extrusion: Polypropylene pellets are melted and extruded into thin tapes.

- Weaving: The tapes are woven together to create the fabric.

- Cutting and Sewing: The fabric is cut and sewn into the desired bag shape.

- Gusseting: The sides are folded and sewn to create the gussets.

- Printing and Finishing: Printing, lamination, or other finishing touches are added as needed. For automated solutions, explore our selection of automatic woven pp bag making machines.

“The manufacturing process is highly efficient,” explains Maria Sanchez, Production Manager at Woven Bag Co. “This contributes to the cost-effectiveness of these bags.”

Environmental Considerations

While durable and reusable, the environmental impact of polypropylene should be considered. Recycling programs are available, and choosing bags made from recycled polypropylene is a sustainable option. Consider exploring options for white woven poly bags for a cleaner look. Also, look into specific importers like pp woven bags importers uk.

Tubular PP Woven Gusseted Bag Recycling

Tubular PP Woven Gusseted Bag Recycling

Conclusion

Tubular PP woven gusseted bags provide a versatile and cost-effective packaging solution across various industries. Their strength, durability, and customizability make them a popular choice for businesses looking for efficient and reliable packaging. Remember to consider the environmental impact and explore recycled options when selecting these bags.

FAQ

- What are the standard sizes available for these bags? Sizes vary depending on the manufacturer and specific application.

- Can these bags be printed with custom designs? Yes, they can be easily customized with printing.

- Are these bags food safe? Food-grade options are available.

- What is the weight capacity of these bags? The weight capacity varies based on the size and construction of the bag.

- How are these bags disposed of? They can be recycled or disposed of in regular waste.

- Are there biodegradable options available? While polypropylene is not inherently biodegradable, biodegradable additives can be incorporated.

- What is the difference between woven and non-woven polypropylene bags? Woven bags are made from woven polypropylene tapes, while non-woven bags are made from bonded polypropylene fibers.

If you need further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.