Woven Bag

Non Woven Bags Making: A Comprehensive Guide

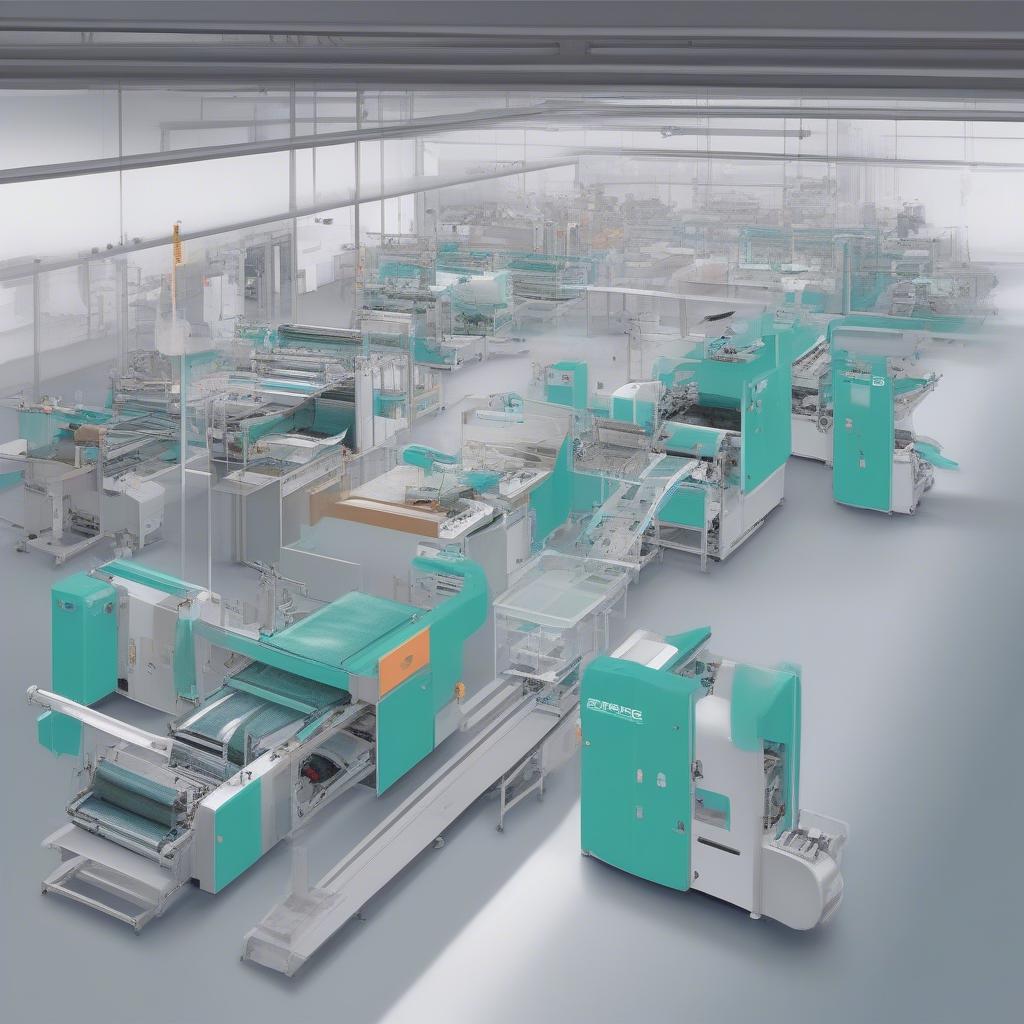

Non Woven Bags Making is a growing industry, driven by the demand for eco-friendly alternatives to plastic bags. This guide delves into the process, materials, and machinery involved in creating these versatile and sustainable carryalls. From raw materials to finished products, we’ll explore everything you need to know about non woven bags making.  Non woven bag production line showing various stages of manufacturing

Non woven bag production line showing various stages of manufacturing

Understanding Non Woven Fabrics

What exactly are non woven fabrics? Unlike woven or knitted materials, non woven fabrics are created by bonding fibers together through mechanical, thermal, or chemical processes. This creates a durable yet flexible material ideal for a variety of applications, including bag making. The resulting fabric is strong, lightweight, and breathable, making it a perfect choice for shopping bags, tote bags, and promotional bags.

What makes non woven bags so popular? They are not only eco-friendly but also cost-effective, making them a smart choice for businesses and consumers alike. Their durability ensures they can be reused multiple times, reducing waste and promoting sustainability. Furthermore, the material is easy to print on, offering excellent branding opportunities.

The Non Woven Bags Making Process

The process of non woven bags making machine starts with the selection of raw materials, typically polypropylene (PP) or polyethylene (PET). These materials are then processed into a web-like structure, which is then bonded to create the non-woven fabric. This fabric is then cut and sewn into the desired bag shape and size.

Key Steps in the Process

- Web Formation: The raw material is melted and extruded into fine fibers, which are then laid down to form a web.

- Bonding: The web is bonded together using heat, chemicals, or mechanical methods, creating the non-woven fabric.

- Cutting: The fabric is cut into the desired shape and size of the bag.

- Stitching/Welding: The edges of the bag are stitched or welded together to create the final product.

- Printing (Optional): Designs or logos can be printed onto the bags for branding purposes.

Automated cutting and stitching process for non woven bags

Automated cutting and stitching process for non woven bags

Machinery Used in Non Woven Bags Making

Several specialized machines are involved in the non woven bags making process, including:

- Non-Woven Fabric Making Machine: This machine creates the non-woven fabric from the raw material. Choosing the right machine for making non woven bags is crucial.

- Cutting Machine: Used to cut the fabric into the desired bag shape.

- Stitching/Welding Machine: Seals the edges of the bag to form the finished product.

- Printing Machine (Optional): Prints designs or logos onto the bags.

You can find more information about non woven bags making machine price on our website. Understanding the cost of machinery is essential for businesses looking to enter this industry.

Raw Materials for Non Woven Bags

Selecting the right raw material for making non woven bags is vital for quality and sustainability. Polypropylene (PP) is a common choice due to its strength, durability, and recyclability.

“Choosing high-quality raw materials is the foundation of creating durable and sustainable non-woven bags,” says Amelia Carter, a leading expert in sustainable textiles. “Using recycled materials further enhances the eco-friendly nature of these products.”

Benefits of Non Woven Bags

- Eco-friendly: Biodegradable and recyclable options are available.

- Cost-effective: Affordable to produce, especially in large quantities.

- Durable: Can withstand regular use and carry heavy loads.

- Customizable: Easy to print on and available in various colors and sizes.

Stacks of finished non woven bags ready for distribution

Stacks of finished non woven bags ready for distribution

Conclusion

Non woven bags making offers a sustainable and cost-effective solution to the growing demand for eco-friendly packaging. Understanding the process, materials, and machinery involved is crucial for businesses looking to capitalize on this growing market. Explore our website for discount machine for making non woven bags. Remember, non woven bags making is more than just a business; it’s a contribution to a greener future.

FAQ

- What are the different types of non-woven fabrics used for bags?

- What is the average lifespan of a non-woven bag?

- Are non-woven bags completely biodegradable?

- What are the printing options for non-woven bags?

- What are the key factors to consider when choosing a non-woven bag making machine?

Need Help? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.