Woven Bag

Optimizing Your PP Woven Bag Pelletizer Line for Efficiency

Pp Woven Bag Pelletizer Lines are crucial for recycling and reusing plastic materials. Understanding how to optimize your pp woven bag pelletizer line can significantly impact your operational efficiency, reduce waste, and contribute to a more sustainable approach to plastic management. This involves careful consideration of the machinery involved, the quality of the input material, and the desired output characteristics. Let’s explore how to maximize the performance of your pp woven bag pelletizer line. what is pp woven bag

Factors Affecting PP Woven Bag Pelletizer Line Efficiency

Several key factors influence the overall efficiency of a pp woven bag pelletizer line. These include the quality of the woven bags, the type and condition of the pelletizer machine, and the operating parameters. Regular maintenance and proper operation are also crucial for optimal performance.

- Quality of Input Material: The condition of the input pp woven bags plays a significant role in the pelletizing process. Bags that are excessively dirty, contaminated with other materials, or degraded can negatively impact the efficiency of the pelletizer line and the quality of the resulting pellets.

- Machine Type and Condition: The specific type of pelletizer machine used, along with its overall condition, directly impacts efficiency. A well-maintained machine with appropriate features for processing pp woven bags will operate more efficiently than an older or poorly maintained machine.

- Operating Parameters: Optimizing parameters like temperature, speed, and pressure is essential for achieving peak performance. These parameters need to be adjusted based on the specific characteristics of the pp woven bags being processed.

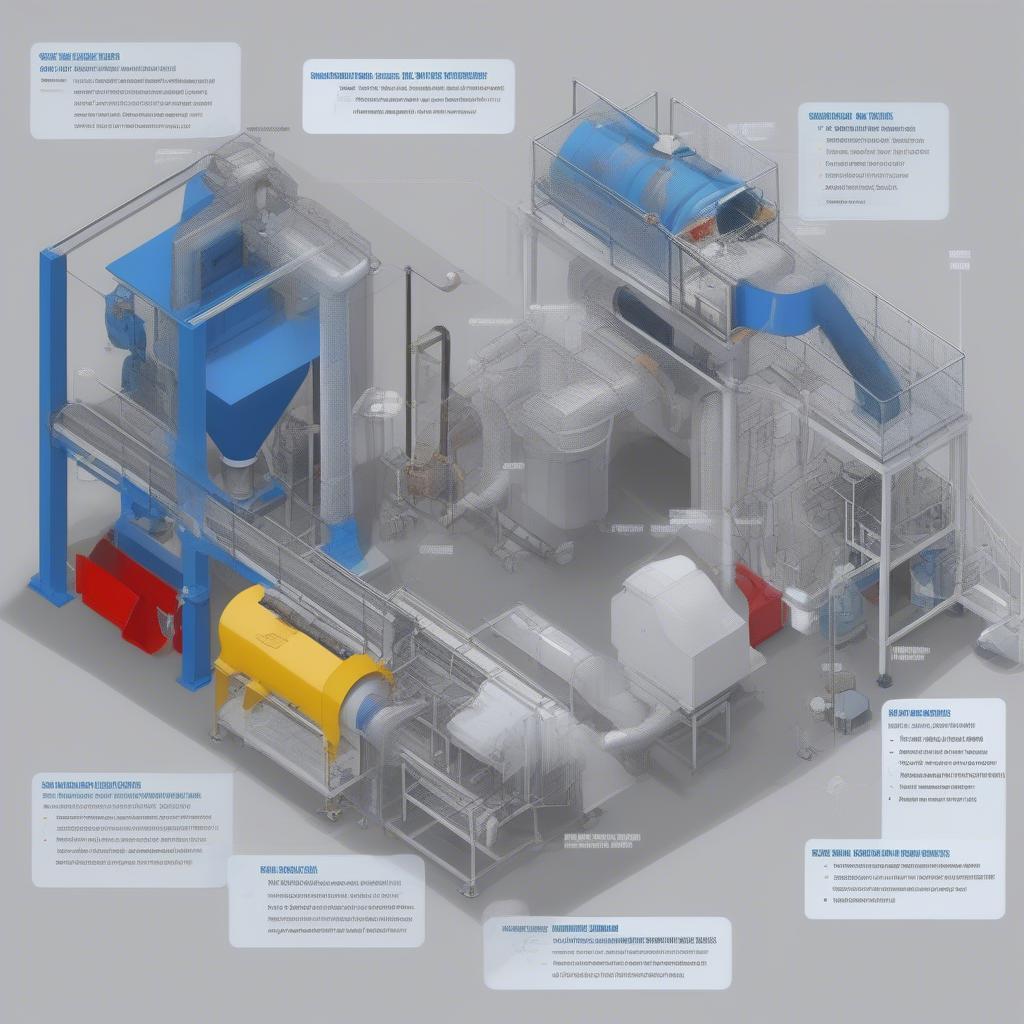

PP Woven Bag Pelletizer Line Components

PP Woven Bag Pelletizer Line Components

Maximizing Output and Minimizing Waste

Achieving maximum output while minimizing waste is the primary goal of any pp woven bag pelletizer line operation. This requires a holistic approach that encompasses both pre-processing steps and the pelletizing process itself.

- Pre-Processing: Implementing effective pre-processing steps, such as sorting and cleaning the pp woven bags, can significantly improve the efficiency of the pelletizing process. Removing contaminants and ensuring a consistent feedstock can enhance output and reduce wear and tear on the machinery.

- Process Optimization: Continuous monitoring and adjustment of the pelletizing process are crucial for maximizing output and minimizing waste. This involves regular checks on temperature, pressure, and other operating parameters to ensure optimal performance.

wholesale pp woven bag pelletizer line

Choosing the Right PP Woven Bag Pelletizer Line

Selecting the appropriate pp woven bag pelletizer line for your specific needs is a crucial decision. Factors to consider include the scale of your operation, the type of pp woven bags you will be processing, and your budget.

- Capacity: Choosing a pelletizer line with the appropriate capacity is essential for meeting your production demands without overspending on equipment.

- Features: Consider the specific features offered by different pelletizer lines. Some machines may be better suited for handling certain types of pp woven bags or may offer advanced features for process optimization.

- Cost: Balancing cost with performance is key. While a more expensive machine may offer greater efficiency and features, it’s important to ensure that the investment aligns with your budget and anticipated return on investment.

PP Woven Bag Pelletizer Line in Operation

PP Woven Bag Pelletizer Line in Operation

“Choosing the right pelletizer line is a crucial investment,” says John Smith, a leading expert in plastic recycling technology. “Consider your long-term needs and prioritize efficiency and reliability.”

Maintenance and Troubleshooting

Regular maintenance is vital for ensuring the long-term performance and reliability of your pp woven bag pelletizer line. A proactive maintenance schedule can prevent costly downtime and extend the lifespan of your equipment.

- Preventive Maintenance: Implementing a preventive maintenance program that includes regular inspections, cleaning, and lubrication can significantly reduce the risk of breakdowns and extend the life of your pelletizer line.

- Troubleshooting: Familiarizing yourself with common troubleshooting techniques and having access to spare parts can minimize downtime in the event of a malfunction.

pp woven bag recycling machine

“Regular maintenance is not just about preventing breakdowns,” adds Jane Doe, a seasoned industrial engineer with extensive experience in plastics processing. “It’s about optimizing performance and ensuring consistent output quality.”

PP Woven Bag Pelletizer Line Maintenance

PP Woven Bag Pelletizer Line Maintenance

waste woven bag recycling machine factory

Conclusion

Optimizing your pp woven bag pelletizer line is a multifaceted process that requires attention to detail and a commitment to continuous improvement. By focusing on factors such as input material quality, machine selection, operating parameters, and maintenance, you can maximize output, minimize waste, and contribute to a more sustainable approach to plastic management. A well-optimized pp woven bag pelletizer line is not only beneficial for your bottom line but also for the environment.

FAQ

- What is a pp woven bag pelletizer line?

- How does a pp woven bag pelletizer line work?

- What are the key components of a pp woven bag pelletizer line?

- What are the benefits of using a pp woven bag pelletizer line?

- How do I choose the right pp woven bag pelletizer line for my needs?

- What are some common troubleshooting tips for pp woven bag pelletizer lines?

- How often should I perform maintenance on my pp woven bag pelletizer line?

For further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team ready to assist you.