Woven Bag

Non-Woven Label Bag Making Machine: A Comprehensive Guide

Non-woven label bag making machines are revolutionizing the packaging industry. These machines offer a cost-effective and efficient way to produce high-quality bags for a variety of applications. This guide will explore everything you need to know about non-woven label bag making machines, from their functionality and benefits to choosing the right machine for your business. woven customizable drawstring bag offers a unique personalized touch.

Understanding Non-Woven Label Bag Making Machines

Non-woven label bag making machines automate the process of creating bags from non-woven fabric, often incorporating labels directly into the bag design during production. This eliminates the need for separate labeling processes, saving time and resources. These machines are designed for high-speed production, ensuring a consistent output of quality bags. They are versatile and can handle different bag sizes and designs, making them suitable for various industries.

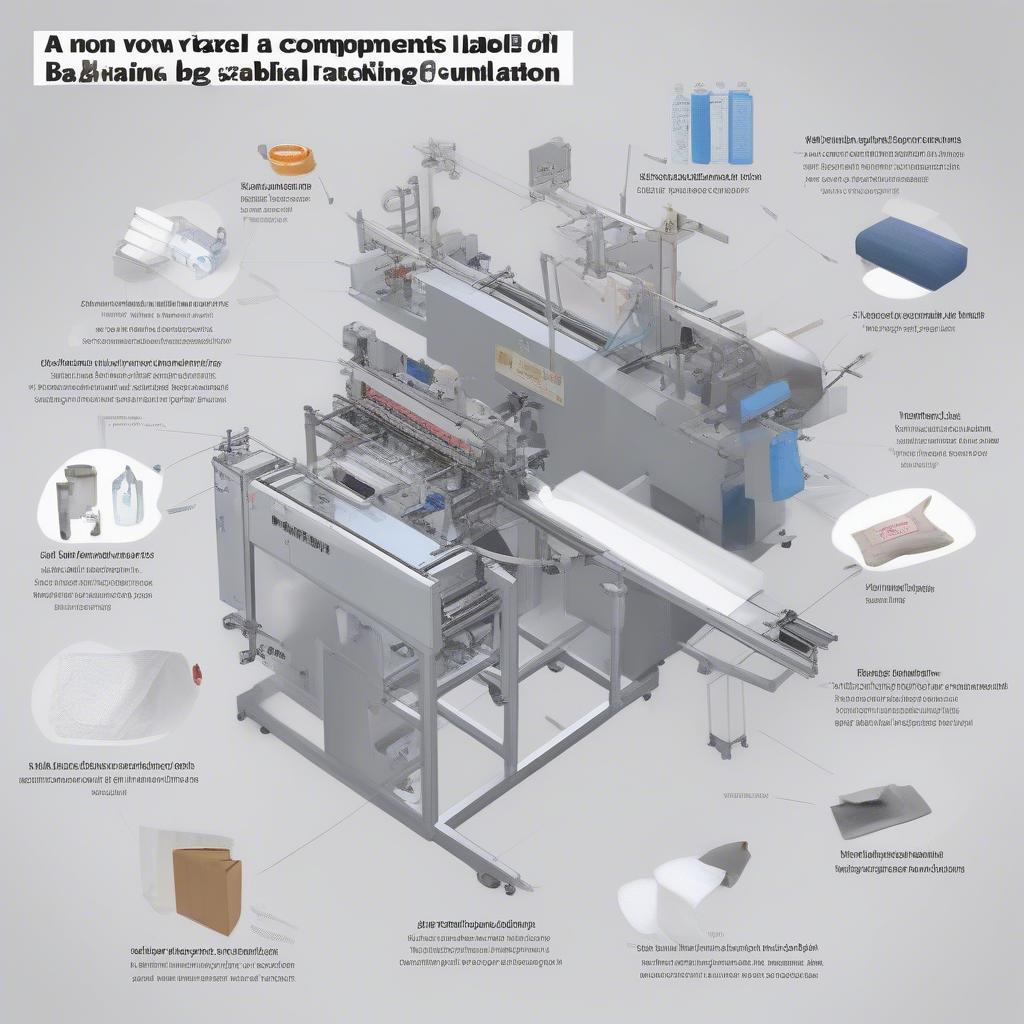

What are the key components of these machines? They typically include feeding mechanisms, cutting units, sealing units, and label applicators. The feeding mechanism ensures a smooth flow of non-woven fabric into the machine. The cutting unit precisely cuts the fabric according to the desired bag dimensions. The sealing unit securely seals the edges of the bag, creating a strong and durable finished product. Finally, the label applicator seamlessly integrates the label into the bag design during the production process.

Non-woven label bag making machine components diagram

Non-woven label bag making machine components diagram

Benefits of Using a Non-Woven Label Bag Making Machine

Investing in a non-woven label bag making machine offers several advantages. Firstly, it significantly increases production efficiency. Automation streamlines the entire bag-making process, resulting in higher output and reduced labor costs. Secondly, it ensures consistent product quality. The automated process minimizes human error, guaranteeing uniformity in bag size, shape, and labeling. Thirdly, it reduces material waste. Precise cutting and sealing mechanisms minimize fabric scrap, optimizing material utilization and reducing overall costs.

What are some other benefits? Customization is another key advantage. These machines can be adjusted to produce various bag sizes and designs, catering to diverse packaging needs. They can also incorporate different label types and placements, offering flexibility in branding and product information. Lastly, they contribute to sustainability efforts by using eco-friendly non-woven materials.

Automated non-woven bag production line

Automated non-woven bag production line

Choosing the Right Non-Woven Label Bag Making Machine

Selecting the appropriate non-woven label bag making machine requires careful consideration of various factors. Production volume is a crucial factor. High-volume operations require machines with greater speed and capacity. Bag size and design requirements influence the choice of machine features and capabilities. used non woven bag offset printing machine can be a cost-effective option for certain businesses. Budget constraints should also be considered, as machines vary in price depending on their features and specifications. Finally, available space and infrastructure needs are important factors in determining the right machine for your facility.

Types of Non-Woven Label Bag Making Machines

Different types of machines cater to specific needs. Some machines specialize in producing bags with handles, while others focus on simple flat bags. what does non woven bag mean provides further insight into the material used in these bags. Machines also vary in their automation level, with some offering fully automated processes while others require manual intervention at certain stages.

“Choosing the right machine is crucial for maximizing efficiency and return on investment,” says John Smith, a leading packaging consultant. “A thorough assessment of your specific needs is essential before making a purchase.”

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and optimal performance of your non-woven label bag making machine. This includes routine cleaning, lubrication, and inspection of key components. non woven bags price in delhi can give you an idea of market pricing. Troubleshooting common issues such as jams or misaligned labels can be handled with basic training and readily available resources.

“Preventive maintenance is key to avoiding costly downtime and repairs,” advises Maria Garcia, a seasoned machine operator. “Regular checks and prompt attention to minor issues can significantly extend the lifespan of your machine.”

Conclusion

Non-woven label bag making machines offer a powerful solution for businesses seeking efficient and cost-effective bag production. manufacturer of pp woven bag offers alternatives for different packaging needs. By understanding the different types of machines, their benefits, and key considerations for selection, businesses can make informed decisions that optimize their packaging operations and contribute to their overall success. Investing in a non-woven label bag making machine is a strategic move that can streamline your processes and enhance your bottom line.

Technician performing maintenance on a non-woven bag making machine

Technician performing maintenance on a non-woven bag making machine

Need assistance? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.