Woven Bag

Non Woven Bag Handle Punching Machine Factory: A Comprehensive Guide

Non woven bag handle punching machines are essential for any business involved in producing non-woven bags. These specialized machines automate the process of creating strong, reliable handles, boosting efficiency and ensuring consistent quality. This guide explores everything you need to know about non woven bag handle punching machine factories, from the intricacies of the machinery to key factors to consider when choosing a supplier. After the introduction, you’ll find a link to more information on non-woven bags.

Understanding Non Woven Bag Handle Punching Machines

Non woven bag handle punching machines are designed to precisely and efficiently punch handles into non-woven fabric. They come in various sizes and configurations, catering to different production needs. Some machines are manually operated, while others are fully automated, integrating seamlessly into large-scale production lines. The choice between manual and automatic machines often depends on the volume of bags being produced and the budget of the manufacturer. Understanding the different types of machines available is crucial for selecting the right equipment for your specific requirements.

Key Features of a Quality Machine

A reliable non woven bag handle punching machine should possess several key features. Durability and precision are paramount, ensuring consistent handle placement and minimizing downtime. Adjustable settings allow for customization based on handle size and bag design. Safety features are also crucial, protecting operators from potential hazards. Speed and efficiency are other important factors to consider, particularly for high-volume production.

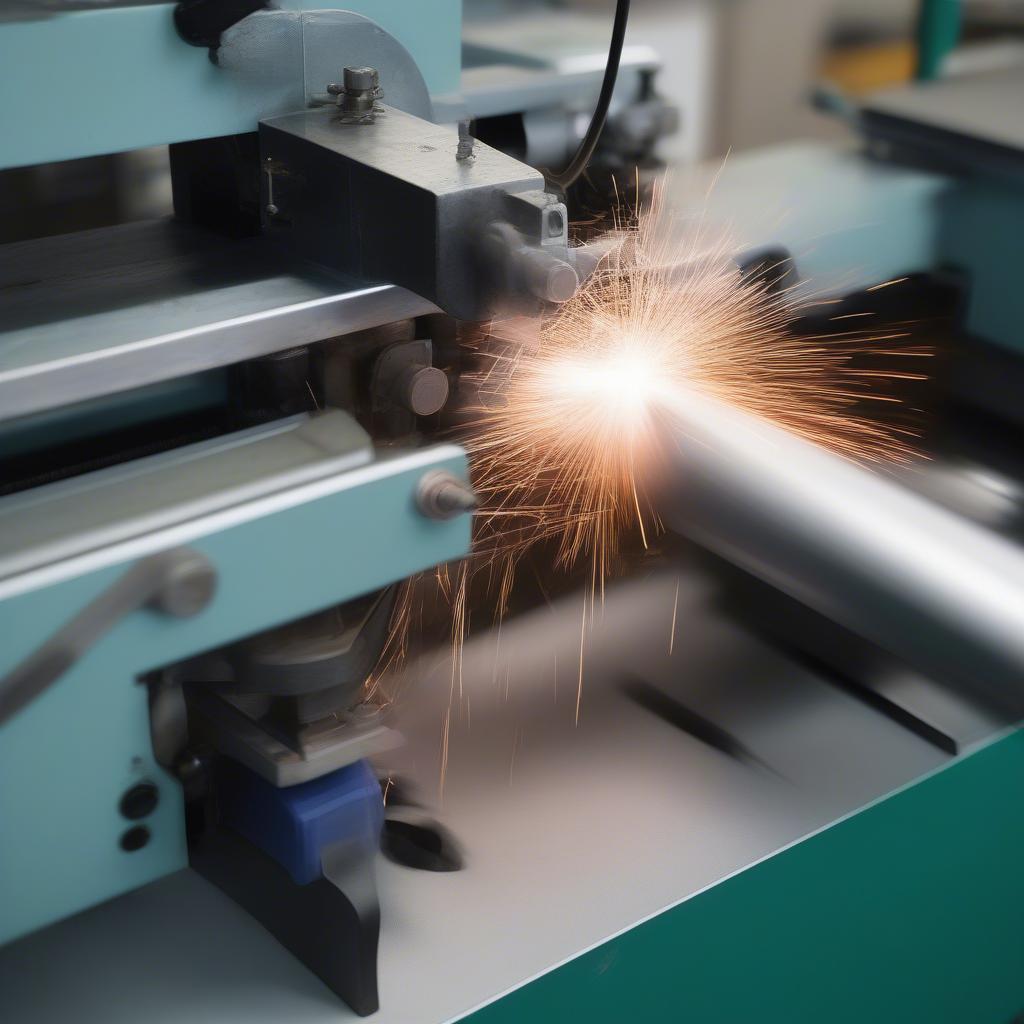

Non-Woven Bag Handle Punching Machine Operating in a Factory

Non-Woven Bag Handle Punching Machine Operating in a Factory

Choosing the Right Non Woven Bag Handle Punching Machine Factory

Selecting the right Non Woven Bag Handle Punching Machine Factory is as important as choosing the machine itself. A reputable factory will offer high-quality machines backed by excellent customer service and technical support. Factors to consider when evaluating a factory include their experience in the industry, the quality of their manufacturing processes, and their commitment to customer satisfaction.

Factors to Consider When Choosing a Factory

- Experience and Reputation: Look for factories with a proven track record of producing reliable and efficient machines.

- Quality Control: Ensure the factory adheres to strict quality control measures throughout the manufacturing process.

- Customer Service and Support: A responsive and helpful customer service team can provide invaluable assistance with installation, maintenance, and troubleshooting.

- Customization Options: Some factories offer customization options, allowing you to tailor the machine to your specific needs.

What questions should I ask a non woven bag handle punching machine factory?

When considering a factory, don’t hesitate to ask about their production capacity, lead times, and warranty policies. Inquire about the availability of spare parts and the training they provide for machine operation and maintenance. A transparent and communicative factory will be happy to answer your questions and address any concerns you may have.

Factory Worker Inspecting a Non-Woven Bag Handle Punching Machine

Factory Worker Inspecting a Non-Woven Bag Handle Punching Machine

Why is investing in a quality non-woven bag handle punching machine important?

Investing in a high-quality non woven bag handle punching machine is a smart decision for any business involved in non-woven bag production. A reliable machine will improve efficiency, reduce labor costs, and ensure consistent handle quality. This will lead to increased productivity, higher profits, and greater customer satisfaction.

w cut non woven bag manufacturing process

“Investing in a top-tier non woven bag handle punching machine is an investment in the future of your business,” says John Smith, CEO of BagWorks Inc. “It’s not just about the machine, it’s about the reliability and consistency it brings to your production process.”

The Future of Non Woven Bag Handle Punching Machines

The non woven bag industry continues to evolve, with increasing demand for sustainable and eco-friendly packaging solutions. Non woven bag handle punching machine factories are adapting to these trends by developing more energy-efficient and versatile machines. Innovation in automation and control systems is also driving the development of smarter machines capable of producing even higher quality handles with increased precision.

Advanced Non-Woven Bag Handle Punching Machine with Automation Features

Advanced Non-Woven Bag Handle Punching Machine with Automation Features

“The future of non-woven bag production lies in automation and sustainability,” says Jane Doe, Lead Engineer at EcoBag Solutions. “We are constantly striving to develop machines that are not only efficient but also environmentally responsible.”

Conclusion

Choosing the right non woven bag handle punching machine factory is a critical decision that can significantly impact your business. By carefully considering the factors outlined in this guide and conducting thorough research, you can select a factory and machine that meets your specific needs and helps your business thrive. Remember, investing in a quality non woven bag handle punching machine is an investment in the future of your bag production operations.

Need help with die-cut bags? Check out this resource: die cut non woven bag factories

For further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team ready to assist you.