Woven Bag

Bopp Laminated Woven Bag: The Ultimate Guide

Bopp Laminated Woven Bags are a popular choice for packaging, offering a blend of durability and visual appeal. This comprehensive guide delves into the world of BOPP laminated woven bags, exploring their benefits, manufacturing process, diverse applications, and the factors to consider when choosing the right one for your needs.  Bopp Laminated Woven Bag Manufacturing Process

Bopp Laminated Woven Bag Manufacturing Process

Understanding Bopp Laminated Woven Bags

Woven bags, typically made from polypropylene (PP), offer excellent strength and resistance to tearing and punctures. The lamination process, using Biaxially Oriented Polypropylene (BOPP) film, adds a protective layer that enhances the bag’s durability, moisture resistance, and printability. This combination results in a packaging solution that is both robust and aesthetically pleasing. These bags are commonly used for various applications, from agricultural products like grains and fertilizers to industrial materials like chemicals and construction supplies.

bopp laminated woven bags are an increasingly popular choice for businesses seeking a cost-effective and versatile packaging option. Their robust construction makes them suitable for transporting heavy goods, while the BOPP lamination provides a barrier against moisture, dust, and other environmental factors.

Benefits of Using Bopp Laminated Woven Bags

- Durability: The combination of woven polypropylene and BOPP film creates a highly durable bag that can withstand rough handling and transportation.

- Moisture Resistance: The BOPP lamination acts as a barrier against moisture, protecting the contents of the bag from damage.

- Printability: The smooth surface of the BOPP film allows for high-quality printing, making it ideal for branding and product information.

- Cost-Effectiveness: Bopp laminated woven bags offer a cost-effective alternative to other packaging materials, especially for bulk goods.

- Versatility: These bags can be customized in various sizes, colors, and designs to meet specific packaging needs.

Applications of Bopp Laminated Woven Bags

Applications of Bopp Laminated Woven Bags

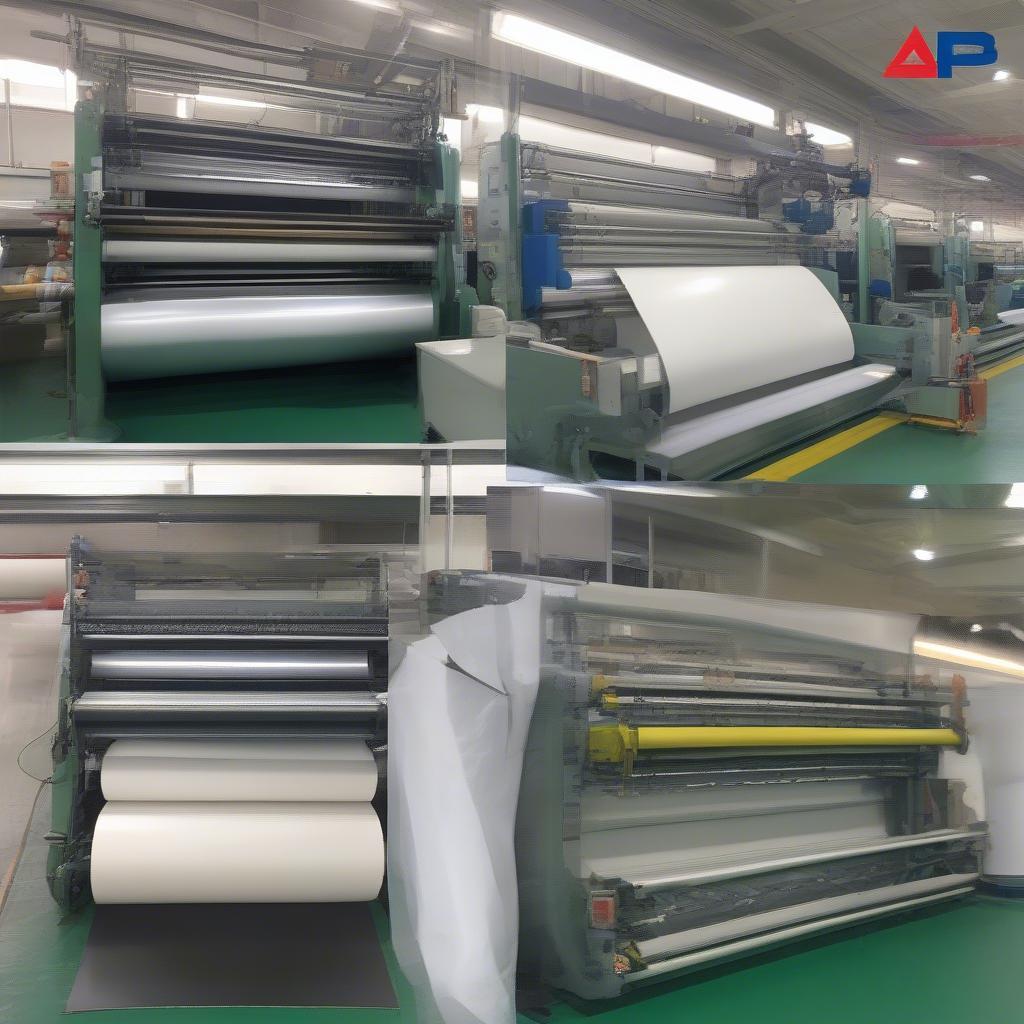

The Manufacturing Process of Bopp Laminated Woven Bags

The production of BOPP laminated woven bags involves several key steps:

- Extrusion: Polypropylene granules are melted and extruded into thin tapes.

- Weaving: The tapes are woven together to form a strong fabric.

- Cutting and Sewing: The woven fabric is cut and sewn into the desired bag shape.

- BOPP Film Lamination: A layer of BOPP film is applied to the woven fabric using heat and pressure.

- Printing (Optional): The laminated bag can be printed with custom designs and branding.

“The quality of the BOPP film is crucial for achieving a high-quality laminated bag,” says John Miller, a packaging specialist with over 20 years of experience. “The film needs to be strong, flexible, and have good adhesion properties to ensure a durable and visually appealing final product.”

Choosing the Right Bopp Laminated Woven Bag

Selecting the right BOPP laminated woven bag involves considering several factors:

- Size and Capacity: Determine the size and weight of the product being packaged to choose the appropriate bag dimensions.

- Material Thickness: The thickness of the woven fabric and BOPP film impacts the bag’s strength and durability.

- Printing Requirements: Consider the design and branding requirements for the bag, including the number of colors and printing method.

- Budget: Bopp laminated woven bags are available in a range of prices, so it’s essential to consider the budget when making a selection.

bopp laminated non woven box bag manufacturer from kolkata offers a wide variety of options for those seeking specialized packaging solutions.

Why Choose Bopp Film Laminated PP Woven Bags?

What makes BOPP film laminated PP woven bags stand out? Their superior properties offer advantages over traditional packaging:

- Enhanced Product Protection: The BOPP lamination provides a barrier against external elements, preserving product quality.

- Improved Brand Visibility: High-quality printing on the BOPP film enhances brand visibility and attracts customers.

- Sustainable Packaging Option: Many BOPP laminated woven bags are recyclable, making them an environmentally friendly choice.

Key Features of Bopp Film Laminated PP Woven Bags

Key Features of Bopp Film Laminated PP Woven Bags

bopp film laminated pp woven bag supplier can provide businesses with tailored solutions to meet their specific packaging requirements. “Investing in high-quality BOPP laminated woven bags can significantly improve a company’s brand image and product protection,” adds Maria Sanchez, a marketing consultant specializing in sustainable packaging.

multicolor printed bopp laminated pp woven sacks bags are an excellent choice for businesses wanting vibrant and eye-catching packaging. bopp laminated pp woven bags manufacturer in india are known for their competitive pricing and quality products.

Conclusion

Bopp laminated woven bags offer a versatile and cost-effective packaging solution for a wide range of industries. By understanding the benefits, manufacturing process, and factors to consider when choosing a bag, businesses can make informed decisions that meet their specific packaging needs. Choosing the right bopp laminated woven bag can enhance product protection, improve brand visibility, and contribute to a more sustainable packaging strategy.

FAQ

- Are BOPP laminated woven bags recyclable?

- What are the standard sizes available for these bags?

- Can I customize the printing on the bags?

- What is the lead time for custom-printed bags?

- What is the weight capacity of these bags?

- Are these bags suitable for food packaging?

- How do I store these bags properly?

Need more help? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.