Woven Bag

Cheap Non Woven Bag Production Line: Your Guide to Affordable & Efficient Manufacturing

Setting up a Cheap Non Woven Bag Production Line requires careful planning and consideration. This guide explores crucial factors like machinery, materials, and operational strategies to help you establish a cost-effective and high-performing production process. We’ll delve into the specifics of creating a production line that meets your budget without compromising quality.

Understanding the Non Woven Bag Production Process

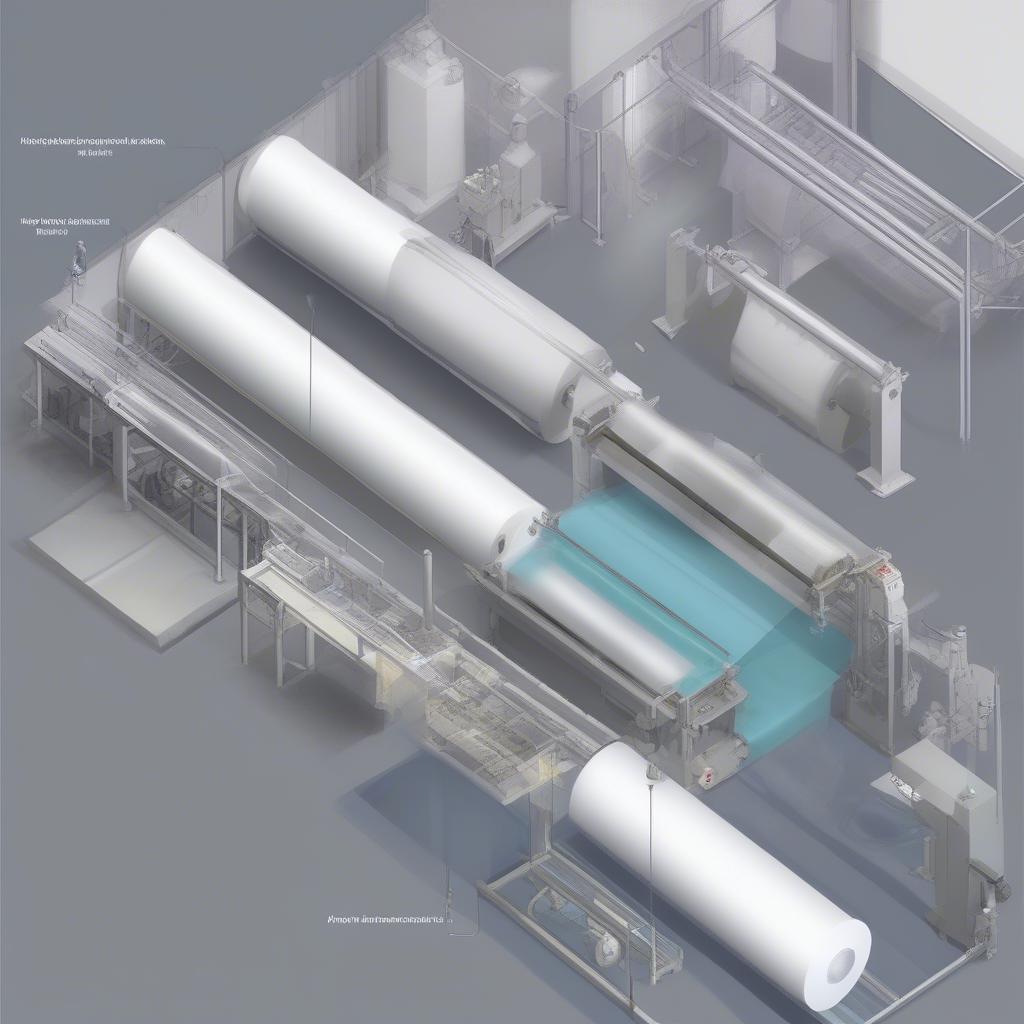

The production of non woven bags involves several key stages, from raw material processing to the finished product. Understanding each step is crucial for optimizing efficiency and minimizing costs. The process typically begins with the preparation of raw materials, which are then fed into a non-woven fabric making machine. This machine transforms the raw materials into a continuous sheet of non-woven fabric.  Non-woven Fabric Production Process

Non-woven Fabric Production Process

Next, the fabric is cut into the desired shape and size for the bags. Handles are attached, and any necessary printing or embellishments are added. Finally, the finished bags are inspected for quality and packaged for distribution. non woven bags manufacturer in nairobi are experienced in setting up and managing this process.

Key Machinery for a Cheap Non Woven Bag Production Line

Investing in the right machinery is paramount to creating a cost-effective production line. While newer, automated machines offer higher output and efficiency, they come with a significant price tag. A cheap non woven bag production line can be achieved by considering used or refurbished machinery, which can offer comparable performance at a fraction of the cost.

Essential machines include a non-woven fabric making machine, a cutting machine, a sewing machine for handle attachment, and a printing machine (if required).  Essential Machinery for Non-Woven Bag Production Finding a reliable non woven bags with logo supplier can help ensure consistent quality and branding.

Essential Machinery for Non-Woven Bag Production Finding a reliable non woven bags with logo supplier can help ensure consistent quality and branding.

Choosing Cost-Effective Raw Materials

Material costs contribute significantly to the overall production expenses. Opting for recycled or readily available materials can significantly reduce costs. Common materials used for non-woven bags include polypropylene (PP) and polyethylene (PE). Exploring different suppliers and negotiating favorable prices can also contribute to a cheaper production line. Understanding the different grades and thicknesses of these materials is vital for balancing cost and quality.

Optimizing Your Production Line for Efficiency

Even with a cheap non woven bag production line, efficiency is key to profitability. Streamlining the production process, minimizing waste, and implementing proper quality control measures can significantly improve output and reduce costs. non-woven fabric bags are increasingly popular due to their durability and reusability.

What are the common challenges in setting up a cheap non-woven bag production line?

Common challenges include sourcing reliable and affordable machinery, managing material costs, and ensuring consistent product quality. Addressing these challenges proactively through careful planning and research is crucial for success. A non woven bag manufacturer in gurgaon can offer valuable insights and support in navigating these challenges.

How can I ensure quality control in a low-cost production setup?

Implementing rigorous quality checks at each stage of the production process is essential, even in a low-cost setup. Regularly inspecting the raw materials, monitoring the machinery performance, and conducting thorough quality checks on the finished products can prevent defects and ensure customer satisfaction.

“Ensuring quality in a cost-effective production line requires a meticulous approach to every stage, from raw material selection to final product inspection,” says Maria Sanchez, Production Manager at EcoBags International.

What are the long-term cost benefits of investing in a non-woven bag production line?

Investing in a non-woven bag production line, even a low-cost one, can offer significant long-term cost benefits. By controlling the production process in-house, you can reduce reliance on external suppliers and gain greater control over costs and quality. printing woven bag murah can enhance brand visibility and marketing efforts.

“In the long run, owning your production line provides significant control over costs and ensures consistent quality, ultimately boosting profitability,” adds John Davis, CEO of Sustainable Packaging Solutions.

Conclusion

Setting up a cheap non woven bag production line requires strategic planning and careful consideration of various factors. By focusing on cost-effective machinery, materials, and efficient operational strategies, you can establish a profitable and sustainable production process. Remember, a well-planned and optimized production line can deliver high-quality non woven bags while keeping costs in check.

FAQs

- What is the typical lifespan of a non-woven bag making machine?

- What are the environmental considerations when setting up a non-woven bag production line?

- How can I find reliable suppliers for raw materials?

- What are the different printing options available for non-woven bags?

- What are the key maintenance requirements for non-woven bag production machinery?

- How can I calculate the return on investment for a non-woven bag production line?

- What are the safety regulations to consider when operating a non-woven bag production line?

Need support? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.