Woven Bag

Discount T-Shirt Bag Non Woven Bag Making Machine: A Comprehensive Guide

Discount T-shirt Bag Non Woven Bag Making Machines are revolutionizing the packaging industry, offering an affordable and efficient way to produce eco-friendly bags. This guide explores everything you need to know about these machines, from their functionalities and benefits to cost considerations and maintenance.  Discount T-Shirt Bag Non Woven Bag Making Machine in Operation

Discount T-Shirt Bag Non Woven Bag Making Machine in Operation

Understanding the Demand for Non-Woven Bags

The shift towards sustainable packaging solutions has fueled the demand for non-woven bags. These bags are durable, reusable, and recyclable, making them a preferred choice for businesses and consumers alike. Non-woven bags are also incredibly versatile, suitable for a wide range of applications, from shopping bags to promotional giveaways. This versatility translates to a greater need for efficient and cost-effective production methods, hence the rise in popularity of discount t-shirt bag non woven bag making machines. These machines cater to the growing demand by offering a streamlined and automated production process.

One of the key advantages of t-shirt non woven bag making machines is their ability to produce bags in large quantities with minimal manual intervention. This not only speeds up production but also reduces labor costs.

Choosing the Right Discount T-Shirt Bag Non Woven Bag Making Machine

Selecting the appropriate machine requires careful consideration of various factors. Production capacity, bag size and design requirements, and budget constraints are crucial aspects to assess before making a purchase. Different machines offer varying levels of automation, speed, and customization options. For instance, some models are specifically designed for high-volume production, while others are better suited for smaller businesses with lower output demands. Understanding your specific needs is paramount to choosing a machine that maximizes efficiency and return on investment.

Key Features to Consider

- Automation Level: Automated features such as automatic cutting and sealing mechanisms can significantly enhance production efficiency.

- Bag Size and Design: Ensure the machine can accommodate your desired bag dimensions and handle any specific design requirements, like printing capabilities.

- Material Compatibility: Verify the machine’s compatibility with different types of non-woven fabrics to offer a broader range of bag options.

- Maintenance and Support: Evaluate the availability of spare parts, technical support, and maintenance services.

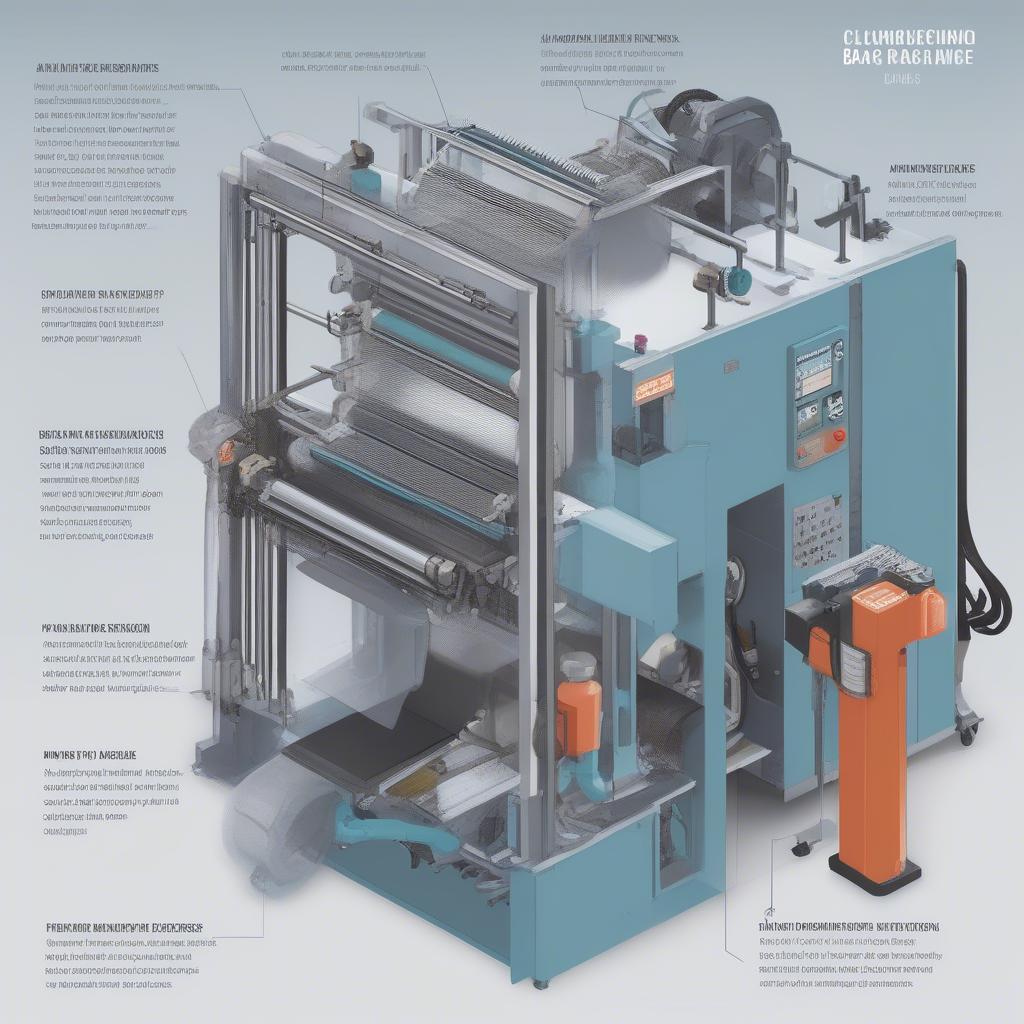

Key Components of a Non-Woven Bag Making Machine

Key Components of a Non-Woven Bag Making Machine

Choosing a non woven bag making machine low price option doesn’t mean compromising on quality. Reputable manufacturers offer machines at competitive prices without sacrificing performance or durability.

Cost Analysis and ROI

While focusing on a discount, remember to analyze the long-term costs. Consider factors such as energy consumption, maintenance requirements, and the cost of raw materials. A slightly more expensive machine with higher energy efficiency and lower maintenance needs might prove more cost-effective in the long run. Calculating the potential return on investment (ROI) is crucial. Estimate the production output, the cost per bag, and the potential revenue to determine the profitability of your investment.

“Investing in a reliable machine is essential for long-term success. A discount doesn’t always mean a bargain; look for value and durability,” says John Smith, a leading expert in sustainable packaging solutions.

Maintenance and Troubleshooting

Proper maintenance is key to extending the lifespan of your machine and ensuring optimal performance. Regular cleaning, lubrication, and inspection of critical components can prevent breakdowns and costly repairs. Establish a preventative maintenance schedule and train your staff on basic troubleshooting procedures. This proactive approach can minimize downtime and maximize productivity.

Knowing where to source non woven garment bag quotes is also helpful for your business.

Maintenance of a Non-Woven Bag Making Machine

Maintenance of a Non-Woven Bag Making Machine

For those looking into other options, researching the pp woven bag making machine price could be a valuable comparison point.

Conclusion

Investing in a discount t-shirt bag non woven bag making machine can be a smart business decision. By carefully considering the factors discussed in this guide, you can choose a machine that meets your production needs, budget, and sustainability goals. Remember to prioritize quality, durability, and after-sales support even when seeking a discounted option. A well-maintained machine will contribute significantly to your business’s profitability and success in the growing non-woven bag market.

FAQ

- What is the average lifespan of a non-woven bag making machine?

- What are the common issues faced with these machines?

- How to choose the right non-woven fabric for different bag types?

- What are the safety precautions to be followed while operating the machine?

- What are the different types of printing options available for non-woven bags?

- What is the typical ROI for investing in a non-woven bag making machine?

- Where can I find reliable suppliers of non-woven fabrics?

For further insights, explore other articles on our website related to sustainable packaging solutions and bag making machinery. We also offer detailed guides on t-shirt bags, garment bags, and different types of woven bag making machines.

When you need assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.