Woven Bag

Fiberglass Non Woven Filter Bags Manufacturer: A Comprehensive Guide

Finding the right Fiberglass Non Woven Filter Bags Manufacturer is crucial for businesses needing efficient filtration solutions. This guide will explore the key factors to consider when choosing a manufacturer, the benefits of fiberglass non woven filter bags, and their various applications.

Understanding Fiberglass Non Woven Filter Bags

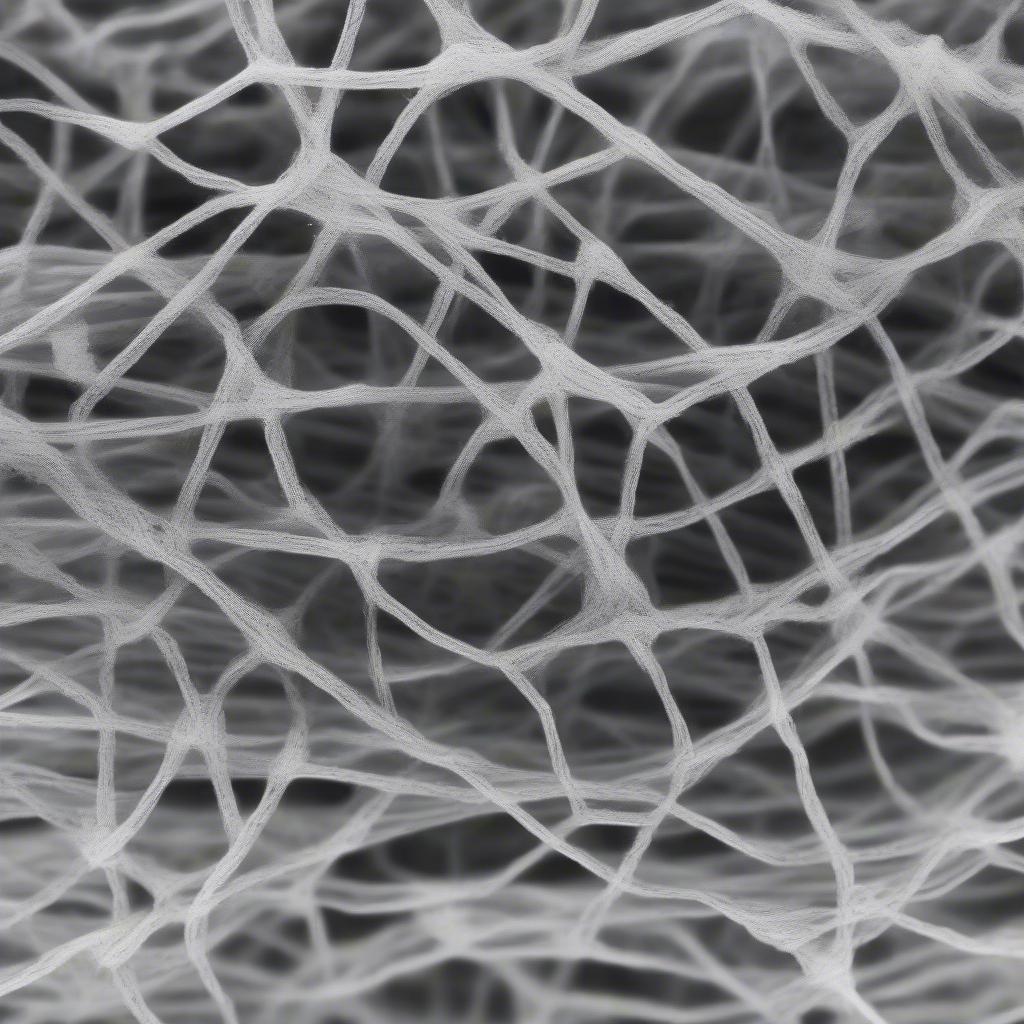

Fiberglass non woven filter bags are essential components in many industrial processes, offering excellent filtration efficiency and durability. Unlike woven fabrics, non woven materials are made by bonding fibers together, creating a unique structure with enhanced filtration properties. These bags are particularly effective in removing particulate matter from gases and liquids.  Fiberglass Non Woven Filter Bag Structure

Fiberglass Non Woven Filter Bag Structure

Choosing a reliable fiberglass non woven filter bags manufacturer can be the difference between a smoothly running operation and costly downtime. Quality, consistency, and expertise are paramount when selecting a supplier.

Key Considerations When Choosing a Manufacturer

- Experience and Expertise: Look for manufacturers with a proven track record in producing high-quality fiberglass non woven filter bags. A manufacturer with years of experience will likely have a deeper understanding of the intricacies of filter bag production.

- Quality Control: A robust quality control system is essential. Ensure the manufacturer adheres to industry standards and conducts rigorous testing to guarantee the performance and durability of their products.

- Customization Options: Different applications require different filter bag specifications. A good manufacturer should offer customization options to meet your specific needs, including size, micron rating, and material.

- Customer Service: Excellent customer service is crucial for a smooth and hassle-free experience. Look for a manufacturer that is responsive, provides technical support, and is committed to customer satisfaction.

Fiberglass Filter Bag Manufacturing Process

Fiberglass Filter Bag Manufacturing Process

Benefits of Fiberglass Non Woven Filter Bags

Fiberglass non woven filter bags offer numerous advantages over other filtration methods. Their unique properties make them suitable for a wide range of demanding applications.

- High Filtration Efficiency: The non woven structure of these bags effectively traps even the smallest particles, ensuring high filtration efficiency.

- Durability and Strength: Fiberglass is inherently strong and resistant to chemicals and high temperatures, making these bags highly durable. This translates to longer service life and reduced replacement costs.

- Temperature Resistance: Fiberglass can withstand high temperatures, making these bags suitable for applications involving hot gases or liquids.

- Chemical Resistance: These bags are resistant to a wide range of chemicals, making them suitable for various industrial processes.

- Cost-Effectiveness: While the initial investment might be higher than other filter bag types, the long lifespan and reduced maintenance make fiberglass non woven filter bags a cost-effective solution in the long run.

What are the advantages of using non-woven filter bags? They provide superior filtration efficiency, durability, and cost-effectiveness compared to other options.

Applications of Fiberglass Non Woven Filter Bags

Non woven filter bags find applications in diverse industries, demonstrating their versatility and effectiveness in various filtration processes.

- Cement Industry: Used to filter dust and particulate matter emitted during cement production.

- Chemical Processing: Used to filter chemicals and ensure product purity.

- Power Generation: Used in coal-fired power plants to control air pollution.

- Pharmaceutical Industry: Used to filter air and liquids in pharmaceutical manufacturing processes.

- Food and Beverage Industry: Used for filtration in various food and beverage processing applications.

Fiberglass Filter Bag Applications

Fiberglass Filter Bag Applications

Finding a Fiberglass Non Woven Filter Bags Manufacturer in Ahmedabad

If you are located in Ahmedabad and searching for a reputable manufacturer, consider factors like local expertise, delivery times, and the ability to visit the facility for inspections.

“Choosing a local manufacturer can be advantageous,” says John Miller, Senior Filtration Engineer at Acme Filtration Solutions. “It can simplify logistics and communication, leading to a more efficient partnership.”

Conclusion

Choosing the right fiberglass non woven filter bags manufacturer is a crucial decision for any business requiring efficient and reliable filtration. By considering factors like experience, quality control, and customization options, you can ensure that you select a partner who can meet your specific needs. PP woven bags manufacturer in Ahmedabad and other woven bags manufacturer in Ahmedabad are also important resources. Remember, investing in high-quality filter bags from a reputable fiberglass non woven filter bags manufacturer will ultimately lead to improved operational efficiency and cost savings.

When do you need to replace fiberglass filter bags? Regular inspection and replacement are crucial to maintain optimal filtration performance. Consult your manufacturer for specific recommendations based on your application.

For assistance, contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.