Woven Bag

Fully Automatic Non Woven Bag Making Machine: A Comprehensive Guide

Fully automatic non-woven bag making machines are revolutionizing the bag manufacturing industry. These machines offer a streamlined and efficient way to produce high-quality non-woven bags, meeting the increasing demand for eco-friendly packaging solutions. This guide delves into the intricacies of these machines, exploring their benefits, features, and applications.

Understanding the Fully Automatic Non Woven Bag Making Machine

A fully automatic non-woven bag making machine is a sophisticated piece of equipment designed to automate the entire process of non-woven bag production. From feeding the raw material to the final cutting and stacking of finished bags, these machines require minimal human intervention. This automation translates to increased production speed, reduced labor costs, and consistent product quality. They are ideal for businesses producing large volumes of non-woven bags, such as shopping bags, tote bags, and promotional bags.

Benefits of Using a Fully Automatic Non Woven Bag Making Machine

Investing in a fully automatic non-woven bag making machine offers numerous advantages:

- Increased Production Capacity: These machines can produce hundreds or even thousands of bags per hour, significantly increasing output compared to manual or semi-automatic methods.

- Reduced Labor Costs: Automation minimizes the need for manual labor, reducing labor costs and associated expenses.

- Improved Product Quality: The precise and consistent operation of these machines ensures consistent bag dimensions, stitching, and overall quality.

- Versatile Production: Many models offer the flexibility to produce various bag styles and sizes, catering to diverse market needs.

- Reduced Material Waste: Automated cutting and sealing minimize material waste, contributing to cost savings and environmental sustainability.

Fully Automatic Non-Woven Bag Making Machine in Operation

Fully Automatic Non-Woven Bag Making Machine in Operation

Key Features of a Fully Automatic Non Woven Bag Making Machine

Modern fully automatic non-woven bag making machines boast a range of features:

- PLC Control System: Programmable Logic Controllers (PLCs) allow for precise control over various machine parameters, including bag size, speed, and cutting patterns.

- Ultrasonic Sealing: Ultrasonic sealing technology creates strong and reliable seams without the need for adhesives or threads, ensuring a clean and durable finish.

- Automatic Material Feeding: Automated feeding systems streamline the production process by continuously supplying raw material to the machine.

- Multiple Bag Style Capabilities: Many machines can produce various bag styles, including D-cut bags, W-cut bags, box bags, and more.

- Waste Recycling System: Some machines incorporate waste recycling systems to minimize material waste and promote sustainability.

Choosing the Right Fully Automatic Non Woven Bag Making Machine

Selecting the right machine depends on specific production requirements. Factors to consider include:

- Production Volume: Choose a machine with a production capacity that aligns with your business needs.

- Bag Styles: Ensure the machine can produce the desired bag styles and sizes.

- Budget: Consider the initial investment cost and ongoing maintenance expenses.

- Supplier Reputation: Choose a reputable supplier with a proven track record of delivering reliable and high-performing machines.

Various Non-Woven Bag Styles Produced by an Automatic Machine

Various Non-Woven Bag Styles Produced by an Automatic Machine

Maintenance and Troubleshooting

Regular maintenance is crucial for optimal machine performance. This includes:

- Cleaning and Lubrication: Regular cleaning and lubrication of moving parts prevent wear and tear.

- Inspection of Electrical Components: Periodically inspect electrical components for damage or loose connections.

- Operator Training: Proper operator training is essential for safe and efficient machine operation.

Future Trends in Non-Woven Bag Making Machinery

The future of non-woven bag making machinery is focused on increased automation, improved efficiency, and enhanced sustainability. Expect to see advancements in areas like:

- Artificial Intelligence Integration: AI-powered machines will optimize production parameters and predict maintenance needs.

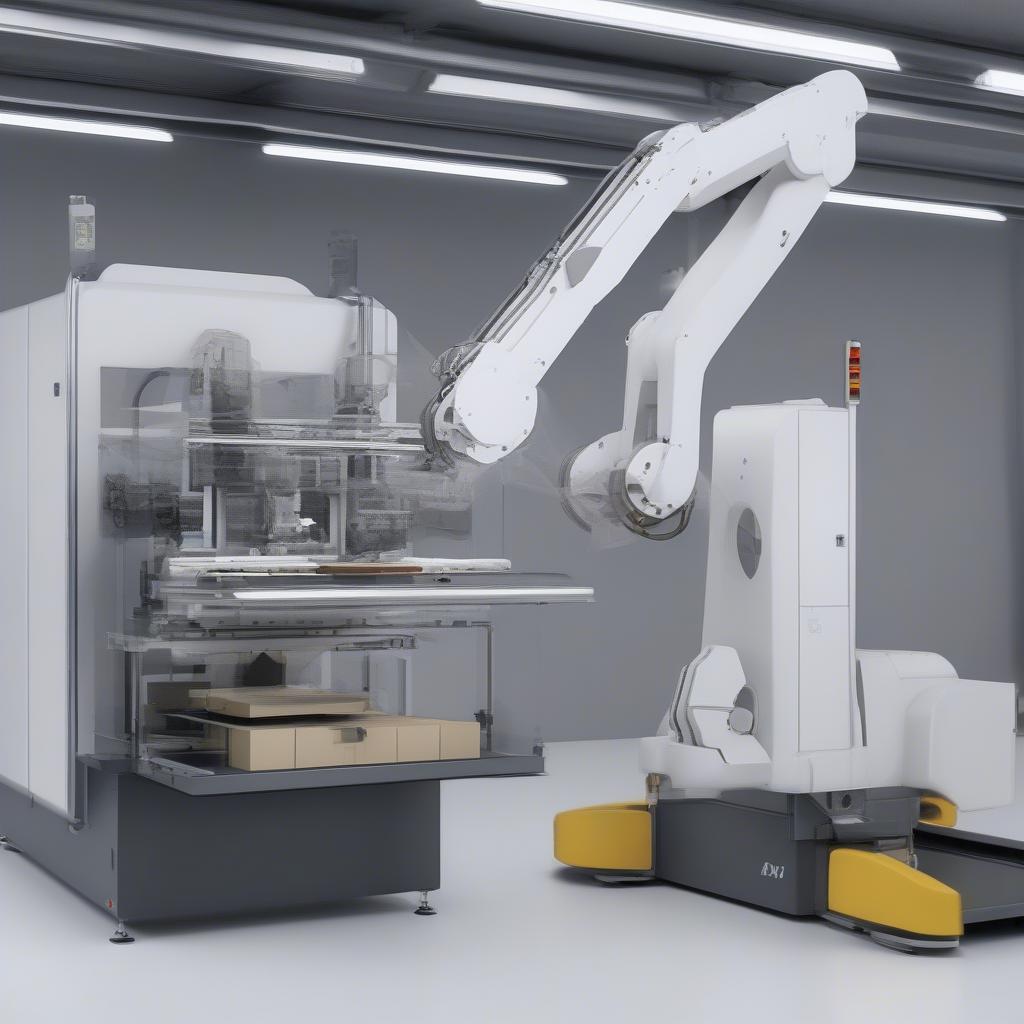

- Robotics Integration: Robotic arms will further automate tasks like material handling and stacking.

- Biodegradable Materials: Machines will be designed to handle a wider range of biodegradable and compostable materials.

Advanced Non-Woven Bag Making Machine with Robotic Arm Integration

Advanced Non-Woven Bag Making Machine with Robotic Arm Integration

Conclusion

The fully automatic non-woven bag making machine is a vital asset for businesses in the packaging industry. Its efficiency, versatility, and cost-effectiveness make it an excellent investment for those seeking to streamline production and meet the growing demand for non-woven bags. Choosing the right machine and implementing a proper maintenance schedule will ensure long-term productivity and profitability.

FAQ

- What is the average lifespan of a fully automatic non-woven bag making machine?

- What are the common types of non-woven fabrics used in bag making?

- How much space is required to install a fully automatic non-woven bag making machine?

- What is the typical return on investment for a fully automatic non-woven bag making machine?

- What are the safety features incorporated in these machines?

- What are the different types of printing options available for non-woven bags?

- How to choose the right supplier for a non-woven bag making machine?

Need support? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.