Woven Bag

How to Make PP Woven Bags: A Comprehensive Guide

Making PP woven bags involves a fascinating process, transforming raw polypropylene pellets into durable and versatile bags. This guide will delve into the intricate steps of PP woven bag production, from raw materials to the finished product. non woven tote bags canada are a popular alternative, but understanding the PP woven bag creation process provides valuable insight into its unique properties.

Understanding the Basics of PP Woven Bag Production

Before diving into the “how-to,” let’s understand what PP woven bags are. These bags are made from woven polypropylene fabric, a thermoplastic polymer known for its strength, flexibility, and resistance to moisture, chemicals, and UV rays. This makes PP woven bags ideal for various applications, from packaging agricultural products to construction materials.

From Pellets to Fabric: The Extrusion Process

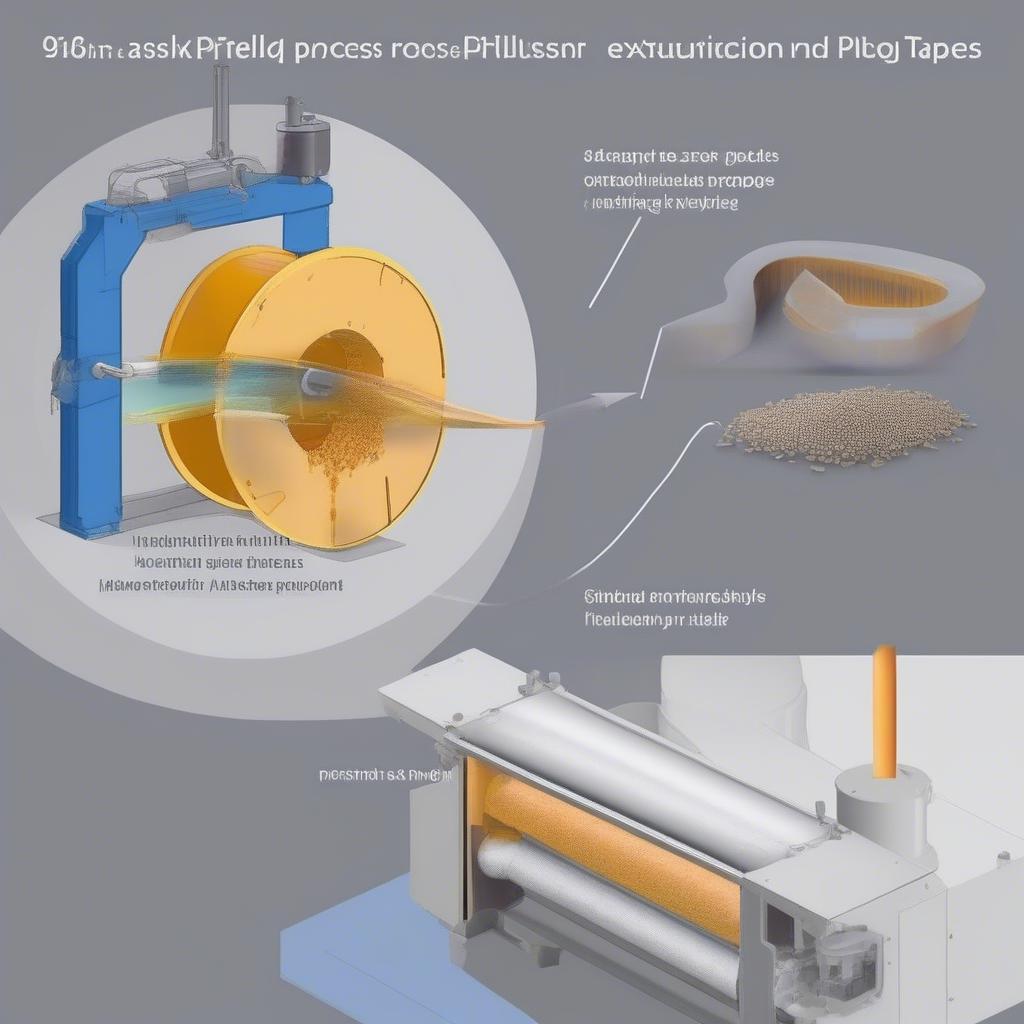

The journey of a PP woven bag begins with polypropylene pellets. These pellets are fed into an extruder, a machine that melts and shapes the plastic. The molten polypropylene is then extruded through a die to create thin, flat tapes. These tapes are the building blocks of the woven fabric.

PP Woven Bag Extrusion Process

PP Woven Bag Extrusion Process

Weaving the Fabric: Circular and Flat Looms

The next stage involves weaving the polypropylene tapes into a fabric. This is typically done on either circular or flat looms. Circular looms produce tubular fabric, ideal for bags, while flat looms create sheets of fabric suitable for other applications. The weaving process interlaces the tapes, giving the fabric its characteristic strength and texture.

The Step-by-Step Guide to Making PP Woven Bags

Now, let’s break down the process of making PP woven bags step-by-step:

- Extrusion: Polypropylene pellets are melted and extruded into tapes.

- Weaving: The tapes are woven into fabric using circular or flat looms.

- Cutting: The woven fabric is cut into the desired size and shape for the bags.

- Printing (Optional): If required, the bags can be printed with logos, designs, or other information. non woven printed box bags offer a similar printing flexibility.

- Sewing: The cut pieces are sewn together to form the bag structure.

- Finishing: Handles, gussets, and other accessories are added to complete the bag.

Choosing the Right Materials: Quality Matters

The quality of the finished PP woven bag depends significantly on the quality of the raw materials. High-quality polypropylene resin ensures a strong, durable, and long-lasting bag. raw material of non woven bags shares similarities with the materials used for PP woven bags, offering further understanding of the importance of quality raw materials.

What are the common sizes of PP woven bags?

PP woven bags come in a wide range of sizes to accommodate various needs, from small bags for groceries to large sacks for industrial materials.

Various Sizes of PP Woven Bags

Various Sizes of PP Woven Bags

Different Types of PP Woven Bags

There’s more to PP woven bags than just size. They come in various types tailored to specific purposes. For example, laminated PP woven bags offer enhanced protection against moisture and dust. Ventilated bags, on the other hand, are designed for products that require breathability. miu miu woven bag showcases a different aesthetic approach to woven materials.

Conclusion: Mastering the Art of PP Woven Bag Making

Making PP woven bags involves a carefully orchestrated process, from the raw polypropylene pellets to the final product. Understanding each stage, from extrusion and weaving to sewing and finishing, is crucial for producing high-quality, durable bags that meet various needs. This knowledge empowers businesses and individuals to make informed decisions about their packaging choices and appreciate the intricate process behind How To Make Pp Woven Bags.

FAQ

- What is the advantage of using PP woven bags? Durability and cost-effectiveness.

- Are PP woven bags recyclable? Yes, they are typically recyclable.

- How are PP woven bags customized? Through printing and adding accessories.

- What industries commonly use PP woven bags? Agriculture, construction, and retail.

- What is the lifespan of a PP woven bag? It varies based on usage and quality, but they are generally long-lasting.

- Where can I find suppliers of PP woven bags? Online directories and industry associations can be helpful resources.

- What is the difference between woven and non-woven bags? Woven bags are made from interlaced tapes, while non-woven bags are made from bonded fibers. non woven bag for bedding provides an example of a non-woven bag application.

Need further assistance with PP woven bags? Contact our hotline at +84 388 951 999 or visit our offices in Hanoi, Vietnam, or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. Our 24/7 customer service team is ready to help.