Basket Weaving

Jute Bag Weaving Machine: A Comprehensive Guide

Jute Bag Weaving Machines are revolutionizing the production of eco-friendly bags. This guide explores everything you need to know about these machines, from their mechanics to their impact on the jute industry. We’ll delve into the different types, their benefits, and how to choose the right one for your needs.

Understanding the Mechanics of a Jute Bag Weaving Machine

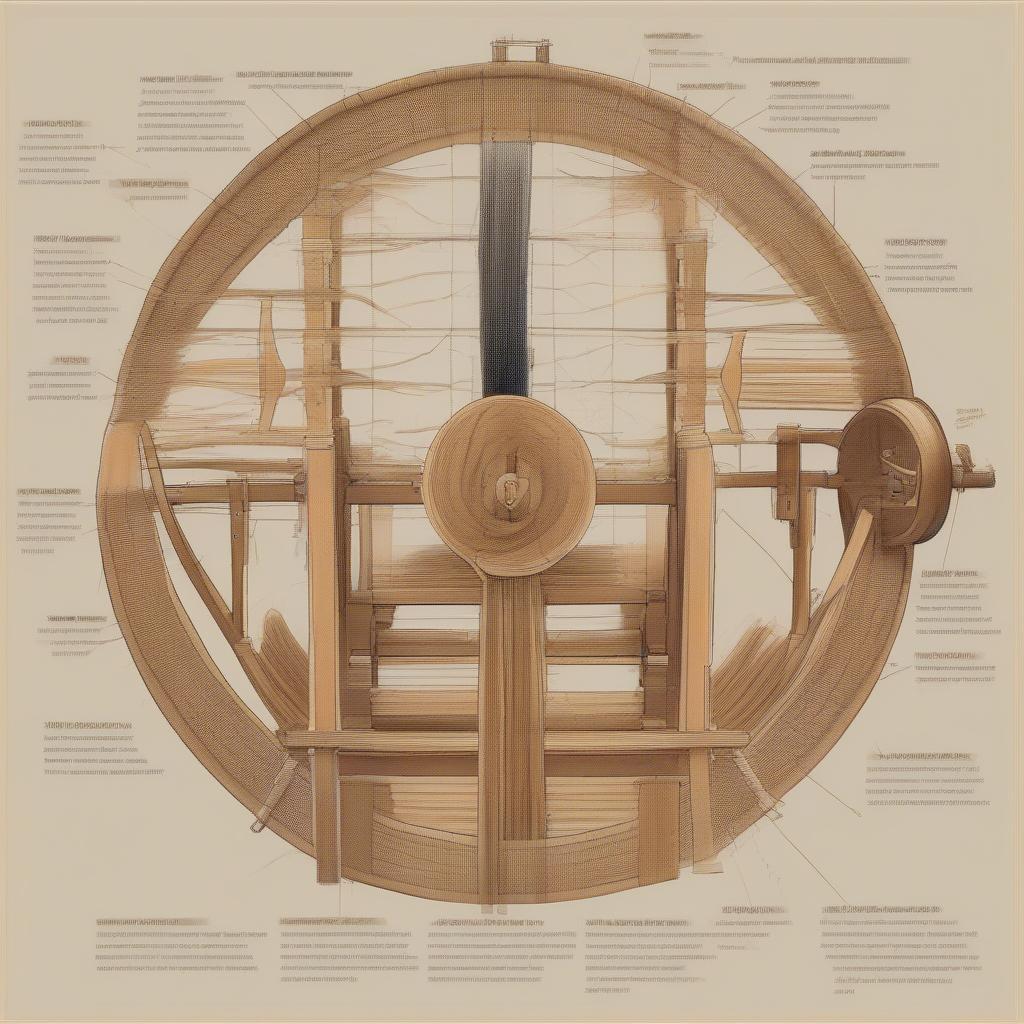

Jute Bag Weaving Machine Mechanics: A detailed diagram showcasing the internal components and working mechanism of a circular loom used for jute bag production.

Jute Bag Weaving Machine Mechanics: A detailed diagram showcasing the internal components and working mechanism of a circular loom used for jute bag production.

Jute bag weaving machines, often circular looms, are sophisticated pieces of machinery designed to interweave jute yarns to create the fabric for bags. These machines automate a process traditionally done by hand, significantly increasing production speed and efficiency. The basic principle involves interlacing warp (longitudinal) and weft (lateral) yarns. The warp yarns are held taut on the loom, while the weft yarn is carried back and forth by a shuttle, creating the woven structure. Different types of looms offer varying levels of automation and complexity.

jute sacking bag rapier weaving machine

Types of Jute Bag Weaving Machines

Several types of jute bag weaving machines cater to different production needs and bag styles. Circular looms are commonly used for producing tubular fabric for bags. These machines operate continuously, weaving a seamless tube of fabric that can be cut and sewn into bags. Other types of looms, such as shuttle looms and rapier looms, can be adapted for jute bag production, offering different weaving patterns and capabilities.

Choosing the Right Jute Bag Weaving Machine

Selecting the appropriate machine depends on various factors, including desired production volume, bag size and design, and budget. Smaller operations might benefit from simpler, manually operated looms, while larger businesses require automated, high-speed machines. Considering the long-term investment, evaluating factors like maintenance requirements and energy efficiency is crucial.

Benefits of Using a Jute Bag Weaving Machine

Benefits of Using a Jute Bag Weaving Machine: Image shows a comparison between manual weaving and machine weaving, highlighting increased production speed, consistent quality, and reduced labor costs.

Benefits of Using a Jute Bag Weaving Machine: Image shows a comparison between manual weaving and machine weaving, highlighting increased production speed, consistent quality, and reduced labor costs.

Jute bag weaving machines offer several advantages over traditional hand-weaving methods. Increased production speed is a primary benefit, allowing manufacturers to meet growing market demands. These machines also ensure consistent quality, producing uniform bags with precise dimensions and weave patterns. Reduced labor costs are another significant advantage, as automation minimizes the need for manual labor.

“Investing in a jute bag weaving machine was a game-changer for our business,” says Sarah Miller, owner of EcoBags Co. “We’ve seen a dramatic increase in our production capacity and a significant improvement in product quality.”

jute sacking bag rapier weaving machine

The Impact on the Jute Industry

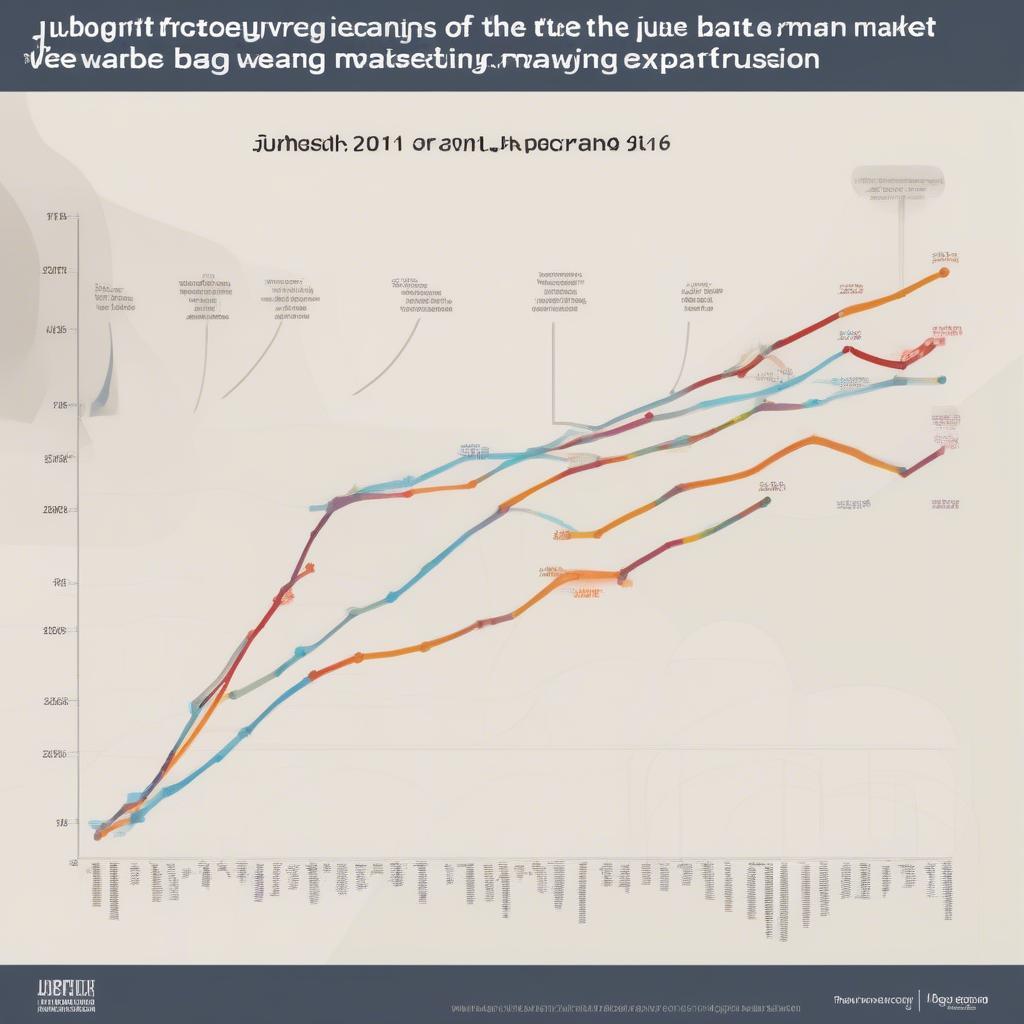

Impact of Jute Bag Weaving Machines on the Industry: Image depicts a graph showing the growth of the jute bag market, correlating it with the adoption of weaving machines.

Impact of Jute Bag Weaving Machines on the Industry: Image depicts a graph showing the growth of the jute bag market, correlating it with the adoption of weaving machines.

Jute bag weaving machines have profoundly impacted the jute industry, driving its modernization and growth. By enabling large-scale production of high-quality jute bags, these machines have helped revive the demand for this sustainable material. The increased efficiency and reduced production costs have made jute bags a competitive alternative to plastic bags, contributing to a more eco-conscious consumer market.

“The development of these machines has not only boosted production but also stimulated innovation in jute bag design and functionality,” adds David Lee, a textile engineer specializing in sustainable materials. “We are seeing more diverse and sophisticated jute bag products entering the market.”

Conclusion

Jute bag weaving machines are pivotal in the modern jute industry, enabling efficient and large-scale production of eco-friendly bags. Understanding the different types of machines, their benefits, and the factors to consider when choosing one is crucial for anyone involved in jute bag manufacturing. Investing in a jute bag weaving machine is an investment in sustainability and the future of eco-conscious packaging.

FAQ

- What are the different types of jute bag weaving machines?

- How does a circular loom work for jute bag production?

- What are the key factors to consider when choosing a jute bag weaving machine?

- How have these machines impacted the jute industry?

- What are the main benefits of using a jute bag weaving machine?

- What is the average cost of a jute bag weaving machine?

- What maintenance is required for a jute bag weaving machine?

Need support? Contact our Hotline: +84 388 951 999, address: Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.