Woven Bag

Laminated Non Woven Bag Making Machine: A Comprehensive Guide

Laminated non-woven bag making machines are revolutionizing the packaging industry. These machines offer efficient and cost-effective solutions for producing high-quality, durable laminated bags suitable for a wide range of applications. From shopping bags to promotional materials, understanding these machines is crucial for businesses seeking to optimize their packaging processes. poly woven bags manufacturer in johannesburg offers insights into different bag manufacturing options.

Understanding Laminated Non Woven Bag Making Machines

Laminated non-woven bags are increasingly popular due to their strength, durability, and eco-friendliness. A laminated non-woven bag making machine automates the process of creating these bags, from feeding the raw material to sealing and cutting the finished product. These machines offer significant advantages in terms of speed, consistency, and labor costs compared to manual production methods.

Laminated Non-Woven Bag Making Machine in Operation

Laminated Non-Woven Bag Making Machine in Operation

Key Features and Functionality

Laminated non-woven bag making machines come equipped with a range of features designed to enhance productivity and quality:

- Automatic Feeding: The machine automatically feeds the non-woven fabric, ensuring a consistent flow of material.

- Lamination Unit: This unit applies a thin layer of film to the non-woven fabric, creating a barrier against moisture and enhancing the bag’s appearance.

- Cutting and Sealing: Precise cutting and sealing mechanisms ensure uniform bag sizes and secure closures.

- Printing Capabilities: Some machines integrate printing capabilities, allowing for custom designs and logos directly onto the bags.

- Adjustable Parameters: Operators can adjust various parameters such as bag size, sealing temperature, and cutting speed to suit specific requirements.

Types of Laminated Non Woven Bag Making Machines

Different types of laminated non-woven bag making machines cater to varying production needs:

- Fully Automatic Machines: These machines offer high-speed production with minimal operator intervention, ideal for large-scale manufacturing.

- Semi-Automatic Machines: These machines require some manual input, offering a balance between automation and flexibility.

- Specialized Machines: Certain machines are designed for specific bag types, such as those with handles or gussets. non woven bag for bedding pricelist provides information on pricing for different types of non-woven bags.

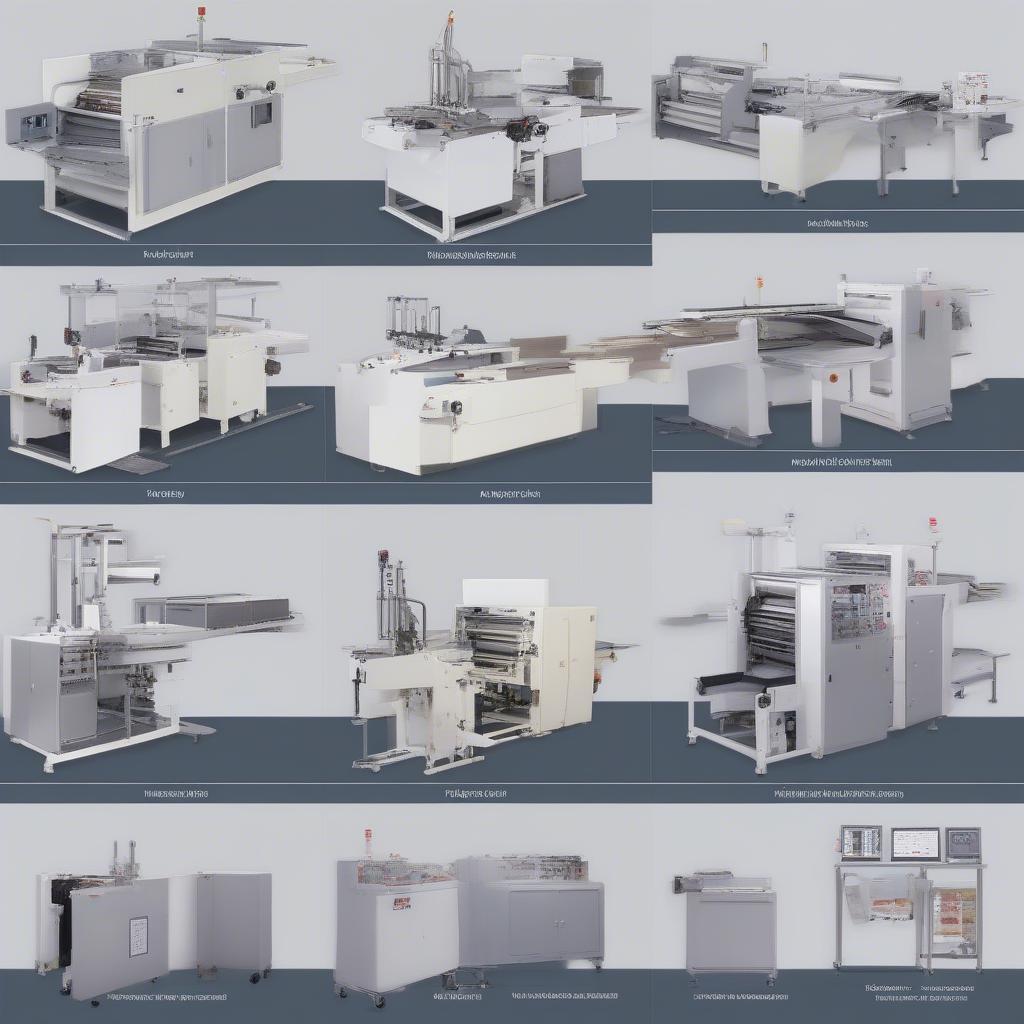

Variations in Laminated Non-Woven Bag Making Machines

Variations in Laminated Non-Woven Bag Making Machines

Choosing the Right Machine

Selecting the right laminated non-woven bag making machine depends on several factors:

- Production Volume: High-volume producers will benefit from fully automatic machines, while smaller operations may find semi-automatic machines more suitable.

- Bag Specifications: The desired bag size, shape, and features will influence the machine choice.

- Budget: Machines range in price based on their features and automation level.

- Available Space: Consider the machine’s footprint and the available space in your facility. polypropylene non-woven fibers grocery bags discusses the growing popularity of these bags.

Benefits of Using a Laminated Non Woven Bag Making Machine

- Increased Efficiency: Automation significantly speeds up the bag production process.

- Consistent Quality: Machines produce uniform bags with precise dimensions and sealing.

- Reduced Labor Costs: Automation minimizes the need for manual labor.

- Enhanced Durability: Lamination improves the bag’s strength and resistance to tearing and moisture.

- Customization Options: Printing capabilities allow for personalized designs.

Advantages of Laminated Non-Woven Bag Making Machines

Advantages of Laminated Non-Woven Bag Making Machines

Conclusion

Laminated non-woven bag making machines are essential for businesses looking to streamline their packaging operations. By automating the bag production process, these machines offer significant advantages in terms of efficiency, quality, and cost-effectiveness. Choosing the right machine involves careful consideration of production volume, bag specifications, and budget. woven polypropylene bags manufacturers usa is a resource for finding bag manufacturers. Investing in a laminated non-woven bag making machine is a strategic move for businesses seeking to optimize their packaging processes and meet the growing demand for durable and eco-friendly bags.

FAQ

- What materials can be used with a laminated non-woven bag making machine?

- What is the average production speed of these machines?

- What maintenance is required for a laminated non-woven bag making machine?

- How much do these machines typically cost?

- What are the different types of lamination available?

- Can these machines produce bags with handles?

- What are the environmental benefits of using non-woven bags?

Common Scenarios and Questions

-

Scenario: A business is considering switching from plastic bags to laminated non-woven bags.

-

Question: What are the cost implications of switching to a laminated non-woven bag making machine?

-

Scenario: A manufacturer needs to produce a large quantity of custom-printed shopping bags.

-

Question: What type of laminated non-woven bag making machine is best suited for high-volume production with printing capabilities? non-woven shopping bag making machine offers more details about this type of machine.

Further Exploration

Explore related articles on our website about sustainable packaging solutions and different bag making technologies.

Contact Us

For assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.