Woven Bag

Laminated PP Woven Bags: The Durable and Versatile Packaging Solution

Laminated Pp Woven Bags are becoming increasingly popular as a packaging solution for various industries. They offer a unique blend of strength, durability, and versatility, making them a cost-effective alternative to traditional packaging materials. This article will delve into the benefits, uses, and manufacturing process of laminated PP woven bags, equipping you with the knowledge to make informed decisions for your packaging needs.

Understanding Laminated PP Woven Bags

What exactly are laminated PP woven bags? They are constructed from polypropylene (PP) woven fabric, a strong and flexible material created by interweaving polypropylene tapes. This woven structure provides inherent strength and tear resistance. The lamination process adds an extra layer of protection, enhancing the bag’s resistance to moisture, dust, and other environmental factors. This lamination can be applied on one or both sides of the bag, depending on the specific requirements.

Structure of a Laminated PP Woven Bag

Structure of a Laminated PP Woven Bag

Benefits of Using Laminated PP Woven Bags

Laminated PP woven bags offer several advantages over other packaging options:

- Durability: The woven construction and lamination make these bags incredibly strong and resistant to tears, punctures, and abrasions.

- Moisture Resistance: The lamination acts as a barrier against moisture, protecting the contents from damage. This is especially crucial for products sensitive to humidity.

- Customizability: These bags can be easily customized with printing, branding, and various sizes and colors to meet specific packaging needs.

- Cost-Effectiveness: Compared to other packaging materials like paper or jute, laminated PP woven bags are often a more economical choice, especially for bulk packaging.

- Reusable and Recyclable: Many laminated PP woven bags are designed for reuse, contributing to sustainability. They are also recyclable, further reducing environmental impact.

Different Types of Laminated PP Woven Bags

Different Types of Laminated PP Woven Bags

Applications of Laminated PP Woven Bags

The versatility of laminated PP woven bags makes them suitable for a wide range of applications across various industries:

- Agriculture: Packaging grains, fertilizers, seeds, and animal feed.

- Construction: Storing and transporting cement, sand, gravel, and other building materials.

- Chemicals: Packaging chemicals, powders, and granules safely.

- Food Industry: Storing and transporting food products like flour, sugar, rice, and pet food.

- Retail: Shopping bags, promotional bags, and packaging for consumer goods.

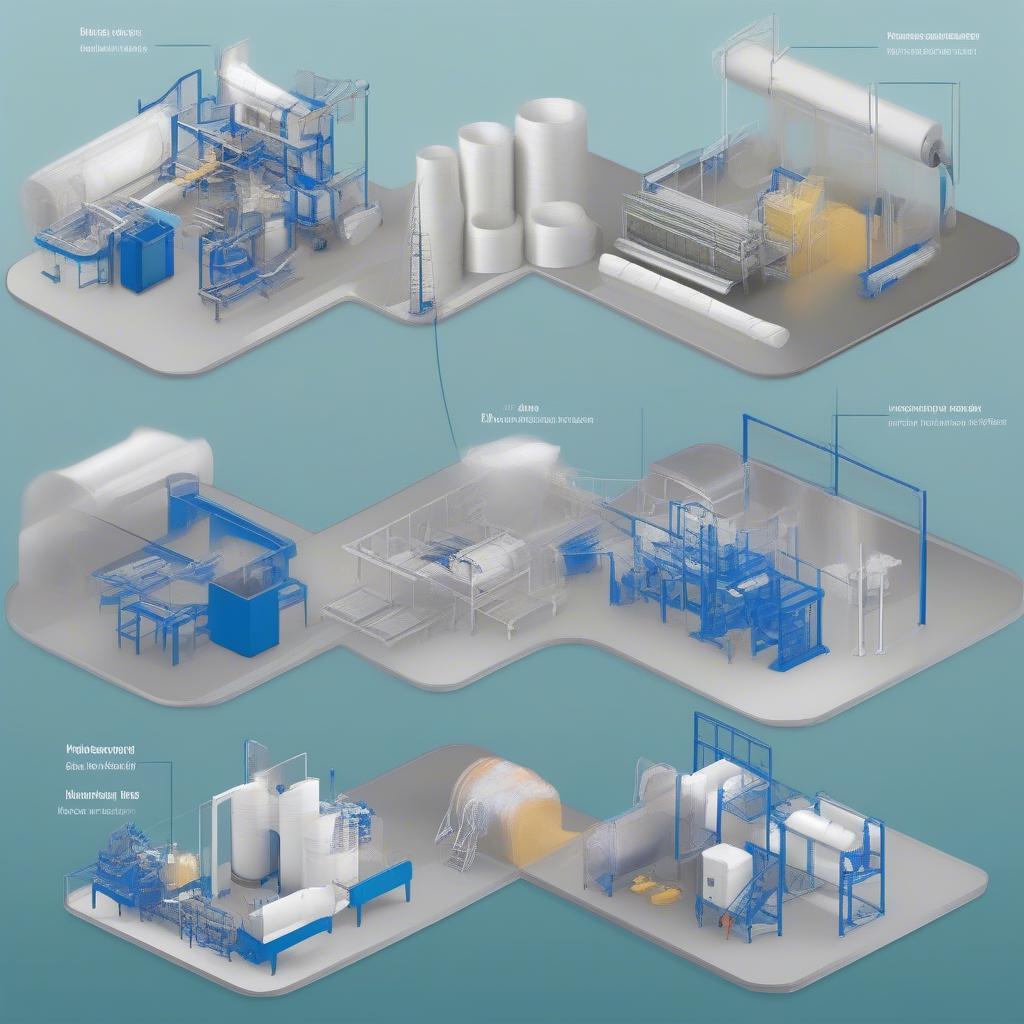

The Manufacturing Process of Laminated PP Woven Bags

The production of laminated PP woven bags involves several key steps:

- Extrusion: Polypropylene pellets are melted and extruded into thin tapes.

- Weaving: These tapes are then woven together on circular looms to create the fabric.

- Lamination: A thin layer of polypropylene film is applied to the woven fabric using heat and pressure.

- Cutting and Stitching: The laminated fabric is cut and stitched into the desired bag shape and size.

- Printing and Finishing: Finally, the bags can be printed with logos, designs, or other information, and additional features like handles or zippers can be added.

Manufacturing Process of PP Woven Bags

Manufacturing Process of PP Woven Bags

Choosing the Right Laminated PP Woven Bag

When selecting a laminated PP woven bag, consider the following factors:

- Size and Capacity: Choose a size appropriate for the product being packaged.

- Lamination Type: Decide whether single-side or double-side lamination is required based on the level of protection needed.

- Printing and Branding: Customize the bags with your logo and branding for enhanced visibility.

- Handles and Closure: Select appropriate handles or closures based on the product and handling requirements.

Conclusion

Laminated PP woven bags provide a durable, versatile, and cost-effective packaging solution for a multitude of industries. Their strength, moisture resistance, and customizability make them an excellent choice for businesses seeking a reliable and sustainable packaging option. By understanding the benefits and applications of these bags, you can make informed decisions that optimize your packaging strategy. Choosing the right laminated PP woven bag will ensure the safe and efficient transport and storage of your products.

FAQ

- What is the difference between woven and laminated PP bags?

- Are laminated PP woven bags recyclable?

- What are the standard sizes available for laminated PP woven bags?

- How much weight can a laminated PP woven bag hold?

- Can laminated PP woven bags be customized with printing?

- What are the advantages of using laminated PP woven bags over paper bags?

- Are laminated PP woven bags suitable for food packaging?

Suggested Further Reading

- Woven Bags vs. Non-Woven Bags: Which is Right for You?

- The Ultimate Guide to Sustainable Packaging

Call us for support at Hotline: +84 388 951 999, or visit our offices in Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team ready to assist you.