Woven Bag

Mastering Non Woven Bag Making Machine Fully Automatic Production

Non Woven Bag Making Machine Fully Automatic technology has revolutionized the bag manufacturing industry. From increasing production speed to reducing labor costs, understanding the intricacies of these machines is crucial for anyone involved in or interested in the world of non-woven bags. This article delves deep into the world of fully automatic non-woven bag making machines, covering everything from their functionality to their benefits and potential drawbacks. discount non woven bag making machine fully automatic.

Understanding the Mechanics of a Non Woven Bag Making Machine Fully Automatic

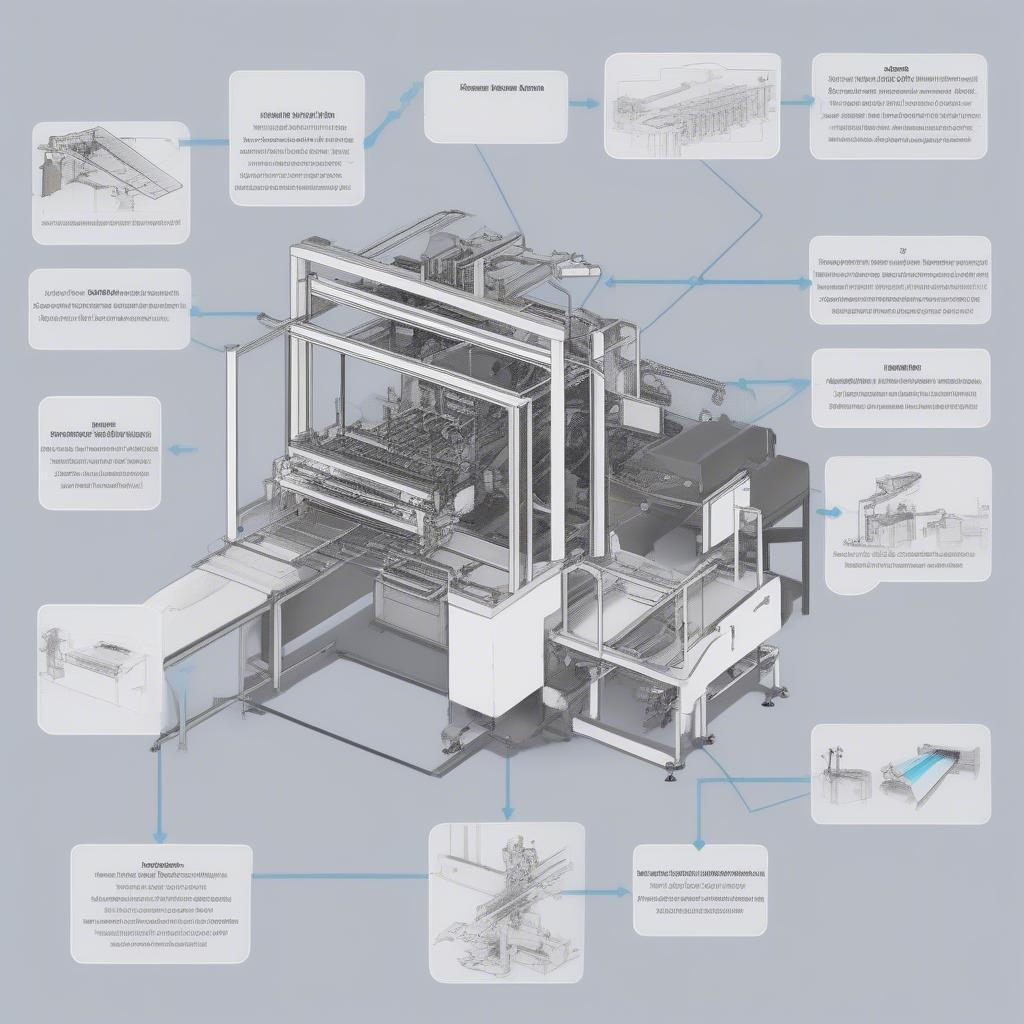

A non woven bag making machine fully automatic operates on a sophisticated system that integrates several processes into a seamless production line. Raw materials, typically polypropylene fabric, are fed into the machine where they are automatically cut, folded, sealed, and ultimately transformed into finished bags. This automation eliminates the need for manual intervention at each stage, significantly boosting efficiency and output. The machine’s computer-controlled interface allows for precise adjustments to bag dimensions, handle placement, and other specifications.

Non-Woven Bag Machine Components

Non-Woven Bag Machine Components

This level of automation not only increases production speed but also ensures consistency in the final product. Each bag is created with the same precision and quality, reducing the chances of errors and inconsistencies that often arise with manual labor. This consistency is crucial for businesses seeking to maintain brand image and customer satisfaction.

Benefits of Implementing a Fully Automatic System

The advantages of using a non woven bag making machine fully automatic are numerous. Increased production speed translates to higher output, enabling businesses to meet large-scale demands efficiently. The reduced need for manual labor significantly lowers labor costs and minimizes the risk of human error. Furthermore, the precise control over bag specifications ensures uniformity and quality in the final product. buy non woven bag making machine fully automatic.

What are the cost savings associated with a non woven bag making machine fully automatic?

The cost savings can be substantial. Reduced labor costs are a major factor, as is the minimized material waste due to the machine’s precision. Additionally, the increased production output allows for quicker turnaround times, leading to faster order fulfillment and potentially increased revenue.

Exploring the Different Types of Non Woven Bag Making Machine Fully Automatic

Several types of fully automatic non-woven bag making machines cater to different bag styles and production needs. Some machines specialize in producing simple handle bags, while others are designed for more complex designs like box bags or bags with gussets. Understanding the different machine types is essential for choosing the right one for your specific requirements.

Different Non-Woven Bag Machine Types

Different Non-Woven Bag Machine Types

How do I choose the right non woven bag making machine fully automatic for my business?

Choosing the right machine depends on factors such as your desired bag style, production volume, and budget. Consulting with industry experts or manufacturers can help you assess your needs and make an informed decision. non woven bag making machine fully automatic manufacturers.

Addressing Potential Challenges and Maintenance

While the benefits are compelling, it’s crucial to be aware of potential challenges. The initial investment cost of a fully automatic machine can be substantial. Regular maintenance and occasional repairs are necessary to ensure optimal performance. Proper training for operators is also essential to maximize efficiency and prevent errors.

Maximizing Efficiency with Your Non Woven Bag Making Machine Fully Automatic

Optimizing machine performance involves regular maintenance, proper material handling, and trained operators. Implementing best practices can significantly improve production output, minimize downtime, and extend the lifespan of the machine. shoulder bag woven.

Non-Woven Bag Machine Maintenance

Non-Woven Bag Machine Maintenance

Conclusion

Investing in a non woven bag making machine fully automatic can be a game-changer for businesses in the bag manufacturing industry. Understanding its functionality, benefits, and potential challenges is essential for making informed decisions and maximizing the return on investment. By embracing this technology, businesses can significantly enhance their production efficiency, reduce costs, and meet the growing demands of the market. For further assistance, contact us in Hanoi, Vietnam or at Tech Avenue, Suite 12, San Francisco, CA 94105, USA. Our customer service team is available 24/7.

FAQ

- What is the average lifespan of a non woven bag making machine fully automatic?

- What kind of training is required to operate these machines?

- How much maintenance is typically involved?

- What are the common issues encountered with these machines?

- What are the different financing options available for purchasing a non woven bag making machine fully automatic?

- How does the machine handle different non-woven fabric thicknesses?

- What safety precautions should be followed when operating a non-woven bag making machine?

You might also be interested in our other articles about discount non woven bag making machine semi automatic.