Woven Bag

Non Woven Bag Making Machine Size: A Comprehensive Guide

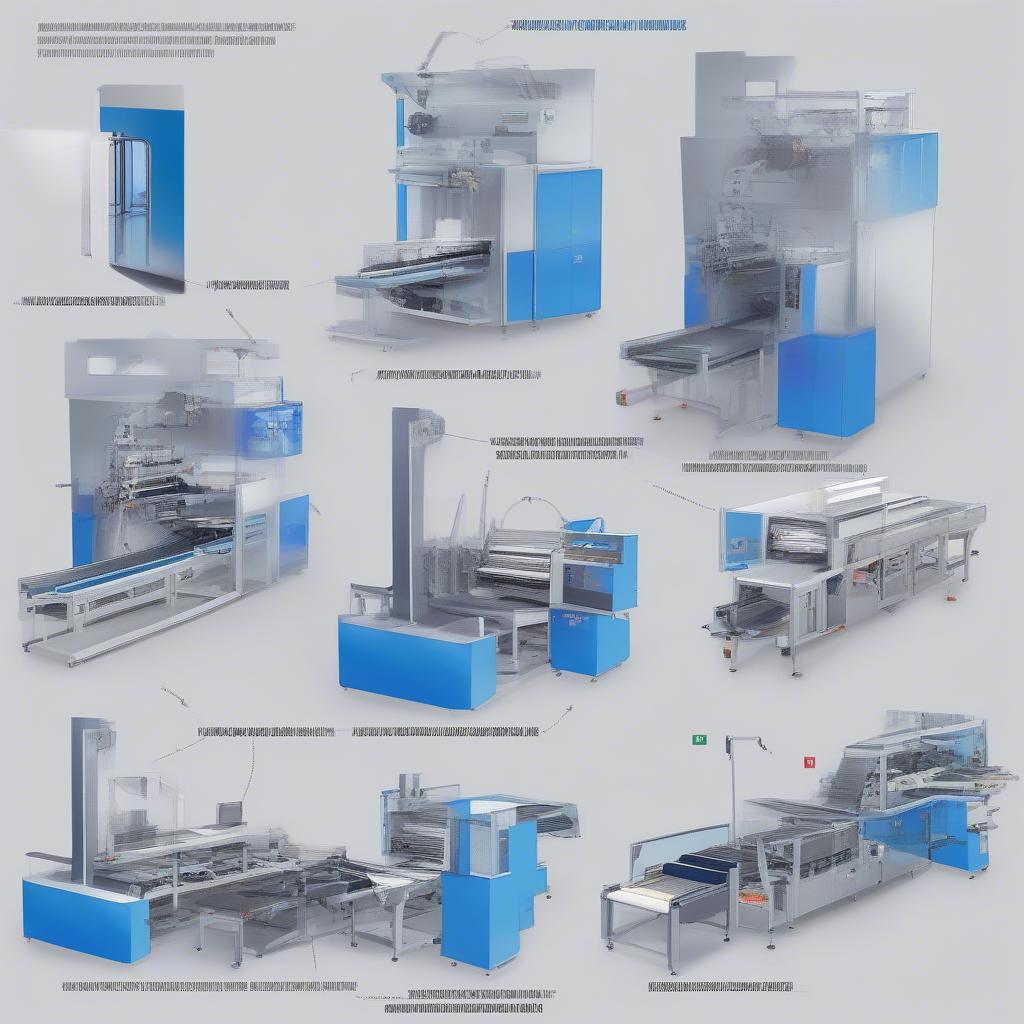

Non Woven Bag Making Machine Size is a crucial factor to consider when choosing equipment for your business. Understanding the various sizes available, and how they relate to production capacity and bag dimensions, will ensure you invest in the right machinery for your specific needs. From small-scale operations to large industrial production, finding the perfect fit is essential for efficiency and profitability.  Non woven bag making machine sizes: Small, medium and large machines in a factory setting

Non woven bag making machine sizes: Small, medium and large machines in a factory setting

Understanding Non Woven Bag Making Machine Sizes

Non woven bag making machines come in a variety of sizes, each designed to accommodate different production volumes and bag dimensions. Choosing the right size is paramount to maximizing efficiency and minimizing waste. Smaller machines are ideal for startups or businesses with limited production requirements, while larger, automated machines cater to high-volume production. Selecting the appropriate size depends on factors like desired bag dimensions, production capacity, and available workspace. non woven shopping box bag making machine suppliers

Factors Influencing Machine Size Selection

Several key factors influence the optimal non woven bag making machine size for your business:

- Desired Bag Dimensions: The size of the bags you intend to produce directly impacts the machine size. Larger bags require machines with wider cutting and sealing mechanisms.

- Production Capacity: How many bags do you need to produce per hour, day, or week? This will determine the speed and automation level required from your machine.

- Available Workspace: The physical space available in your facility will dictate the maximum size of the machine you can accommodate.

- Budget: Larger machines typically come with a higher price tag. Consider your budget and prioritize features that align with your production needs.

Imagine needing to produce thousands of large shopping bags daily. A small, manual machine would be inadequate. Conversely, investing in a large, automated machine for a small business producing a limited number of small bags would be unnecessary and costly.

Exploring Different Machine Sizes and Their Applications

Non woven bag making machines can be broadly categorized into small, medium, and large sizes. Each category caters to different production scales and bag types.  Applications of non woven bag making machines

Applications of non woven bag making machines

Small Non Woven Bag Making Machines

These compact machines are perfect for small businesses, startups, or those with limited space. They are generally manually operated and ideal for producing smaller bags like gift bags or promotional bags.

Medium Non Woven Bag Making Machines

Medium-sized machines offer a balance between affordability and production capacity. They are often semi-automated and suitable for producing a wider range of bag sizes and styles, including shopping bags and tote bags. non woven bags price list in chennai

Large Non Woven Bag Making Machines

These fully automated machines are designed for high-volume production. They can handle large bag sizes and complex designs, making them ideal for large manufacturers supplying retailers or industrial clients. fully automatic non woven bag making machine in china

“Choosing the right machine size is like choosing the right tool for the job,” says Maria Sanchez, a leading industrial engineer specializing in textile manufacturing. “A small hammer won’t build a house, and a sledgehammer is overkill for hanging a picture.”

Key Considerations for Choosing the Right Size

Beyond the basic size categories, several technical specifications play a vital role in determining the suitability of a non woven bag making machine.

- Cutting Width: This determines the maximum width of the bag that can be produced.

- Production Speed: Measured in bags per minute or hour, this metric indicates the machine’s output capacity.

- Automation Level: From manual feeding to fully automated systems, the level of automation impacts production efficiency and labor costs.

Automation levels of non-woven bag making machines

Automation levels of non-woven bag making machines

folding non woven bag factories

“Don’t just focus on the initial cost of the machine,” advises John Davis, a seasoned consultant in the packaging industry. “Consider the long-term operational costs, including maintenance, repairs, and energy consumption. A slightly more expensive, high-quality machine can save you money in the long run.”

Conclusion

Selecting the appropriate non woven bag making machine size is crucial for optimizing your production process and achieving your business goals. Carefully consider your desired bag dimensions, production capacity, available workspace, and budget to make an informed decision. Remember, investing in the right machine size is an investment in your business’s future success. basket round bag woven

FAQ

- What is the average size of a non woven bag making machine?

- How do I determine the right machine size for my production needs?

- What are the price ranges for different sizes of non woven bag making machines?

- What are the maintenance requirements for a non woven bag making machine?

- What are the safety features to look for in a non woven bag making machine?

- Can I upgrade a smaller machine to increase its production capacity?

- What are the different types of non-woven fabrics that can be used with these machines?

If you need assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.