Woven Bag

Non Woven Bag Manufacturing Machine: A Comprehensive Guide

Non Woven Bag Manufacturing Machines are revolutionizing the packaging industry. From simple shopping bags to complex industrial packaging, these machines offer efficient and cost-effective solutions for creating a wide range of non-woven products. This guide dives deep into the world of non-woven bag manufacturing, exploring the different types of machines, their benefits, and key considerations for businesses looking to invest in this technology. non woven carry bags manufacturing machine price

Understanding Non Woven Bag Manufacturing Machines

Non woven bag making machines produce bags from non-woven fabric, a material created by bonding fibers together through mechanical, thermal, or chemical processes. Unlike woven fabrics, non-woven materials don’t require weaving or knitting, resulting in a faster and more economical production process. These machines automate the process of cutting, sealing, and shaping the non-woven fabric into bags of varying sizes and designs.

Types of Non Woven Bag Manufacturing Machines

Several types of non-woven bag manufacturing machines cater to different production needs. Some common types include:

- Fully Automatic Machines: These high-speed machines handle the entire bag-making process with minimal human intervention, ideal for large-scale production.

- Semi-Automatic Machines: Offering a balance between automation and manual control, semi-automatic machines are suitable for medium-scale production and businesses requiring more flexibility in bag design.

- Specialized Machines: These machines are designed for specific bag types, such as drawstring bags, handle bags, or bags with complex designs.

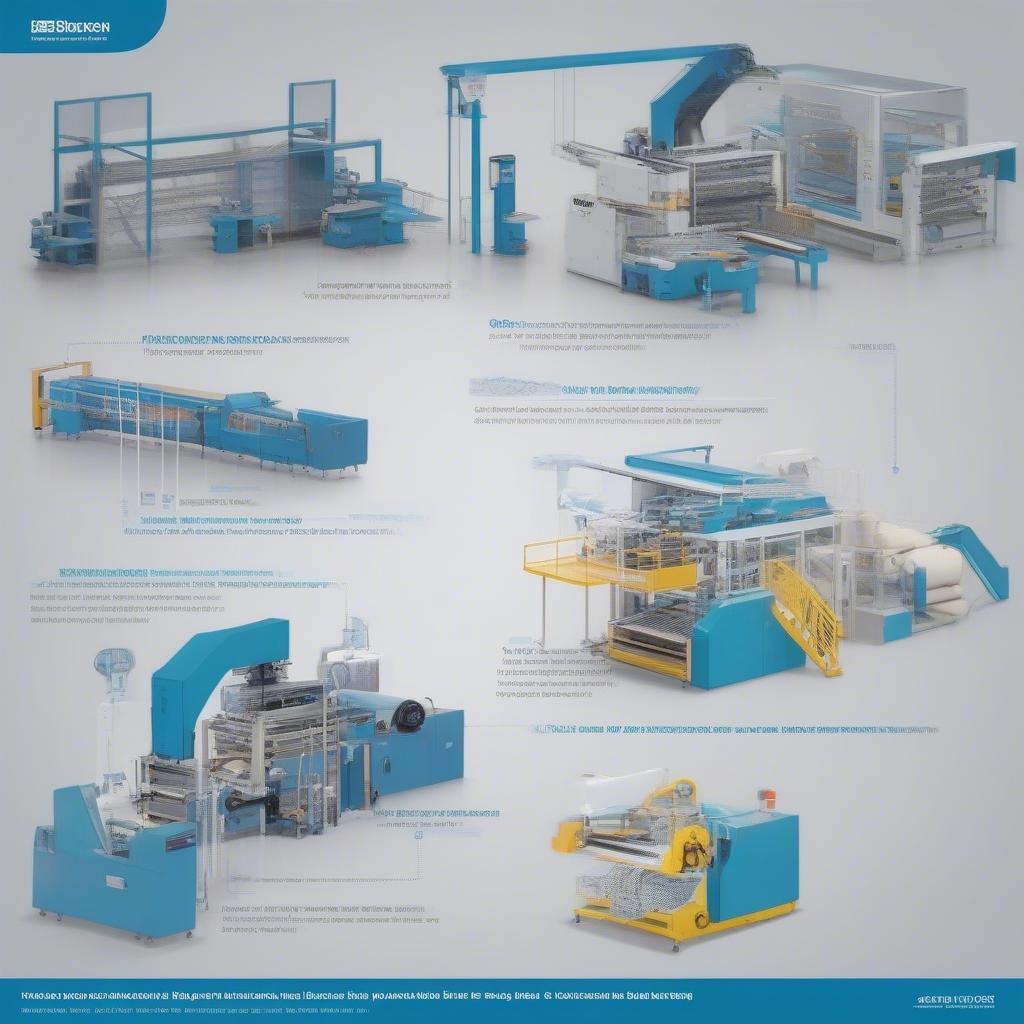

Different Types of Non-Woven Bag Making Machines

Different Types of Non-Woven Bag Making Machines

Benefits of Using Non Woven Bag Manufacturing Machines

Investing in a non-woven bag manufacturing machine offers numerous advantages:

- Increased Productivity: Automation significantly speeds up the bag-making process, allowing businesses to meet high demand.

- Cost-Effectiveness: Reduced labor costs and efficient material usage contribute to lower production costs.

- Consistent Quality: Automated processes ensure uniform bag quality and minimize errors.

- Design Flexibility: Modern machines offer versatile design options, allowing for customization in bag size, shape, and features.

“Investing in a reliable non-woven bag manufacturing machine is a game-changer for any business looking to optimize their packaging operations,” says Amelia Carter, a leading industrial engineer specializing in sustainable packaging solutions. “The efficiency and consistency offered by these machines can significantly boost productivity and profitability.”

non woven bags manufacturers in delhi

Key Considerations When Choosing a Non Woven Bag Manufacturing Machine

Selecting the right non-woven bag manufacturing machine requires careful consideration of several factors:

- Production Capacity: Assess your current and future production needs to choose a machine that can handle the required volume.

- Bag Specifications: Consider the desired bag size, shape, and features, such as handles or gussets.

- Budget: Establish a clear budget and explore machines within your price range.

- Maintenance and Support: Ensure the manufacturer provides adequate after-sales service and support.

Factors to Consider When Selecting a Non-Woven Bag Making Machine

Factors to Consider When Selecting a Non-Woven Bag Making Machine

How Does a Non Woven Bag Manufacturing Machine Work?

The basic operation of a non-woven bag manufacturing machine involves several steps:

- Material Feeding: The non-woven fabric roll is loaded onto the machine.

- Cutting: The machine cuts the fabric into the desired shape.

- Sealing: The edges of the fabric are sealed using heat or ultrasonic welding.

- Handle Attachment (if applicable): Handles are attached to the bag.

- Stacking: Finished bags are stacked and collected.

“Understanding the operational process of these machines is crucial for maximizing their efficiency and ensuring smooth production,” advises David Miller, a seasoned production manager with extensive experience in the non-woven bag industry.

non woven bag making machine suppliers

Operational Process of a Non-Woven Bag Manufacturing Machine

Operational Process of a Non-Woven Bag Manufacturing Machine

Conclusion

Non woven bag manufacturing machines are essential tools for businesses in the packaging industry. By automating the bag-making process, these machines offer increased productivity, cost-effectiveness, and consistent quality. Carefully considering factors like production capacity, bag specifications, and budget is crucial for selecting the right machine for your business needs. Investing in a high-quality non woven bag manufacturing machine can significantly enhance your packaging operations and contribute to overall business growth.

FAQ

- What is the lifespan of a non-woven bag manufacturing machine?

- What are the common maintenance requirements for these machines?

- What are the different types of non-woven fabrics suitable for bag making?

- How much space is required to install a non-woven bag manufacturing machine?

- What safety precautions should be taken while operating these machines?

- What are the different printing options available for customizing non-woven bags?

- What are the environmental benefits of using non-woven bags?

Need help? Contact our 24/7 customer service team at Hotline: +84 388 951 999, Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA.