Woven Bag

Demystifying the Non-Woven Bag Manufacturing Process

The non-woven bag manufacturing process is more intricate than it might initially appear. From raw materials to finished product, each step plays a crucial role in creating these ubiquitous carriers. This article delves into the fascinating journey of non-woven bag production, exploring the techniques, materials, and machinery involved.

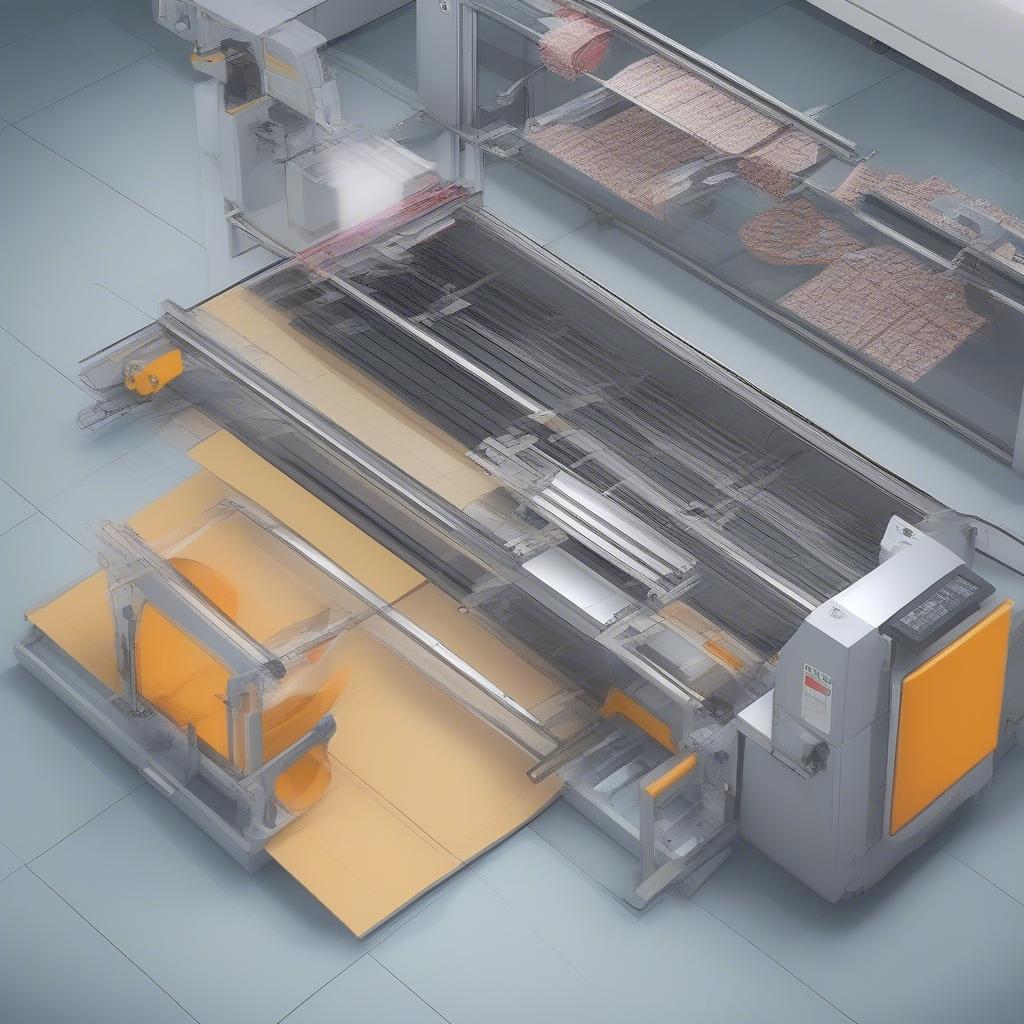

Non-woven fabric production line showing the different stages of the process

Non-woven fabric production line showing the different stages of the process

Non-woven fabrics, unlike their woven counterparts, are made directly from fibers bonded together by chemical, mechanical, or thermal processes. This makes them a versatile and cost-effective material, particularly suitable for bag manufacturing. non woven bags manufacturing process involve a series of steps, each contributing to the final product’s quality and durability.

Understanding the Key Stages of Non-Woven Bag Manufacturing

The non-woven bag manufacturing process typically comprises several key stages: web formation, bonding, cutting, printing, and sewing. Each stage is crucial for creating a durable and aesthetically pleasing final product.

Web Formation: Laying the Foundation

The journey begins with the creation of a web, a sheet of loosely arranged fibers. Several methods achieve this, including spunbonding, meltblowing, and airlaid. Each method lends specific characteristics to the final fabric.

Web formation process in non-woven fabric production

Web formation process in non-woven fabric production

Bonding: Giving the Fabric Strength

The formed web is then bonded to provide strength and integrity. Methods include thermal bonding, chemical bonding, and mechanical bonding, each impacting the fabric’s texture, strength, and drape. This step is critical for non woven carry bags manufacturing process as it determines the bag’s durability.

Cutting and Shaping: Creating the Bag’s Form

Once bonded, the fabric is cut into the desired bag shape. Precise measurements and sharp cutting tools ensure consistent bag size and shape, minimizing waste. This process can involve die-cutting for complex shapes or simple cutting for basic designs.

Cutting and sewing process of non-woven bags in a factory

Cutting and sewing process of non-woven bags in a factory

Printing and Decoration: Adding Personality

Printing adds branding, designs, or other decorative elements to the bags. Techniques such as screen printing, flexography, and digital printing allow for a wide range of customization options.

Sewing and Finishing: Bringing it all Together

Finally, the cut pieces are sewn together to create the bag’s final form. This often involves adding handles, reinforcing seams, and other finishing touches. Understanding non woven fabric bag manufacturing process provides insights into the various customization options available.

Choosing the Right Manufacturing Process: Key Considerations

Several factors influence the selection of a specific non-woven bag manufacturing process. These include the desired bag properties, production volume, budget, and environmental impact.

- Material Selection: Different fiber types offer varying properties in terms of strength, softness, and eco-friendliness.

- Production Volume: High-volume production often necessitates automated processes, while smaller runs may benefit from more manual methods.

- Budget Constraints: Manufacturing costs can vary significantly depending on the chosen process and materials.

- Environmental Impact: Sustainable manufacturing practices are becoming increasingly important, with a growing demand for eco-friendly materials and processes. For insights on this, consider w cut non woven bag manufacturing process.

Conclusion: The Future of Non-Woven Bag Manufacturing

The non-woven bag manufacturing process continues to evolve, driven by technological advancements and growing consumer demand for sustainable and personalized products. Understanding non woven bag manufacturing process is crucial for both consumers and businesses looking to make informed choices. From material selection to printing and finishing, each stage offers opportunities for customization and innovation.

FAQ

- What are the advantages of non-woven bags?

- How are non-woven bags different from woven bags?

- What materials are used to make non-woven bags?

- Is the non-woven bag manufacturing process environmentally friendly?

- Can non-woven bags be recycled?

- What are the different types of non-woven bags available?

- How do I choose the right non-woven bag for my needs?

Need assistance? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.