Woven Bag

Non Woven Bag Sealing Machine: A Comprehensive Guide

Non Woven Bag Sealing Machines are essential for businesses producing non-woven bags. These machines efficiently seal various bag types, ensuring product safety and a professional finish. From understanding different machine types to exploring pricing and maintenance, this guide provides a comprehensive overview of non woven bag sealing machines.

Understanding Non Woven Bag Sealing Machines

Non-woven bags are ubiquitous, used for shopping, packaging, and various other applications. Their widespread use necessitates efficient sealing solutions, and this is where non woven bag sealing machines come into play. These machines offer a quick and reliable way to seal bags, guaranteeing product protection and enhancing the overall presentation. They come in various types, each catering to specific needs and production scales. ultrasonic non woven bag sealing machine offer precise and efficient sealing.

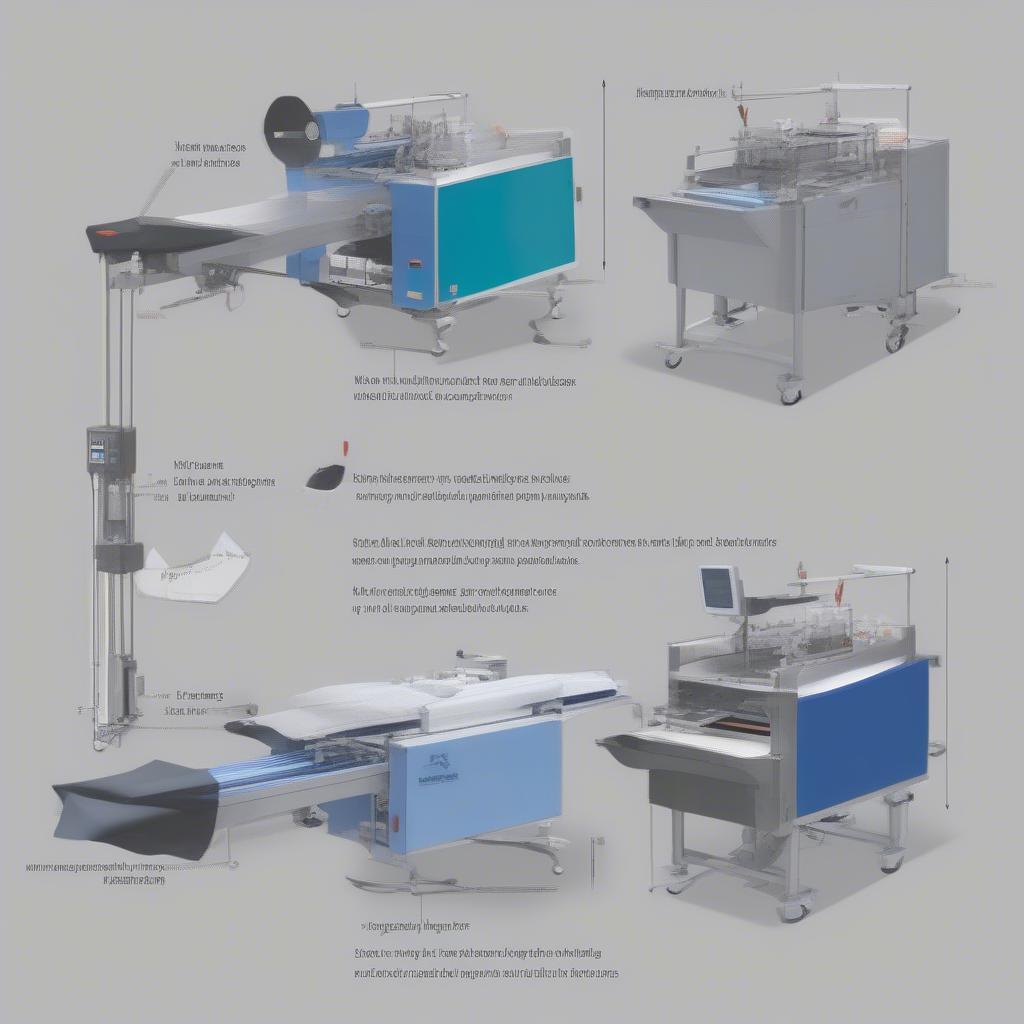

Non-Woven Bag Sealing Machine in Operation

Non-Woven Bag Sealing Machine in Operation

Different Types of Non Woven Bag Sealing Machines

Several types of non woven bag sealing machines exist, each designed with specific features and functionalities. Understanding the distinctions between these machine types helps businesses choose the right equipment for their unique production requirements. Common types include ultrasonic sealers, heat sealers, and impulse sealers. Choosing the right machine depends on factors like bag material, production volume, and desired seal quality. non woven bag sealing machine manufacturers offer a wide range of machines tailored to different needs.

Ultrasonic Non Woven Bag Sealing Machines

Ultrasonic non woven bag sealing machines utilize high-frequency vibrations to create a strong and reliable seal. They are known for their speed, precision, and ability to seal various materials effectively. This makes them a popular choice for businesses requiring high-volume production and consistent seal quality.

Heat Sealers

Heat sealers use heat to melt and fuse the edges of the bag together. These machines are generally more affordable than ultrasonic sealers, making them a viable option for smaller businesses or those with lower production volumes.

Impulse Sealers

Impulse sealers apply a quick burst of heat to create a seal. They are often used for sealing thinner materials and offer a cost-effective solution for light-duty sealing applications. ultrasonic non woven bag sealing machine price in india varies depending on the features and functionalities.

Different Types of Non-Woven Bag Sealing Machines

Different Types of Non-Woven Bag Sealing Machines

Factors to Consider When Choosing a Non Woven Bag Sealing Machine

Choosing the right non woven bag sealing machine involves considering several factors, including bag material, production volume, budget, and desired seal quality. Evaluating these factors carefully ensures selecting a machine that aligns with specific production requirements.

“Selecting the appropriate sealing machine is crucial for optimizing production efficiency,” says John Smith, a leading packaging consultant. “It’s about finding the right balance between functionality, cost, and long-term performance.”

Bag Material and Thickness

Different bag materials require different sealing methods. Thicker materials may necessitate a more powerful machine, while thinner materials might be suited to a simpler sealing process.

Production Volume

The required production volume significantly impacts machine selection. High-volume operations benefit from automated and high-speed machines, while lower-volume operations might be better served by smaller, manually operated machines.

Budget Considerations

Non woven bag sealing machines vary in price, depending on their features, functionalities, and brand. Establishing a budget beforehand helps narrow down the options and facilitates informed decision-making.

Maintaining Your Non Woven Bag Sealing Machine

Regular maintenance is crucial for ensuring the longevity and optimal performance of a non woven bag sealing machine. Proper cleaning, lubrication, and periodic inspections can prevent costly repairs and downtime. non woven bag sealing machine price in india can be a substantial investment, and regular maintenance helps protect it. ultrasonic non woven bag sealing machine parts can be sourced for replacements or repairs.

“Regular maintenance is the key to extending the lifespan of your sealing machine,” advises Maria Garcia, a seasoned manufacturing engineer. “Preventive measures can minimize downtime and ensure consistent production output.”

Conclusion

Non woven bag sealing machines are vital for businesses in the packaging industry. Choosing the right machine requires careful consideration of various factors, and proper maintenance ensures long-term performance. By understanding the different machine types and implementing a regular maintenance schedule, businesses can optimize their packaging processes and achieve efficient and reliable bag sealing.

FAQ:

- What are the different types of non woven bag sealing machines?

- How do I choose the right non woven bag sealing machine for my business?

- What are the key maintenance steps for a non woven bag sealing machine?

- Where can I find non woven bag sealing machine manufacturers?

- What is the price range for non woven bag sealing machines in India?

- What are the benefits of using an ultrasonic non woven bag sealing machine?

- Where can I find replacement parts for my ultrasonic non woven bag sealing machine?

Need help? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have 24/7 customer support.