Woven Bag

Non Woven Bag Stitching Machine Price: A Comprehensive Guide

Finding the right Non Woven Bag Stitching Machine Price can be a daunting task, especially with so many options on the market. This guide will explore the factors influencing price, different machine types, and tips for finding the best deal. We’ll also delve into the world of non-woven bag production, from raw materials to finished products. heavy duty woven bags

Understanding Non Woven Bag Stitching Machines

Non-woven bags have become ubiquitous, replacing traditional plastic bags in many applications. These eco-friendly alternatives require specialized machinery for their creation. Non woven bag stitching machines are designed to efficiently and effectively sew together the fabric panels of these bags. Different machines offer varying speeds, features, and levels of automation, all of which impact the final non woven bag stitching machine price.

Types of Non Woven Bag Stitching Machines

Several types of non woven bag stitching machines cater to different production needs and budgets:

- Manual Machines: These entry-level machines offer basic stitching functionalities at a lower price point. They’re suitable for small-scale production or businesses just starting.

- Semi-Automatic Machines: These machines offer a balance of manual control and automated features, increasing production speed and efficiency. They are ideal for mid-sized businesses.

- Fully Automatic Machines: These high-end machines offer complete automation, including fabric feeding, cutting, and stitching. They are designed for large-scale production and high-volume output.

Types of Non-Woven Bag Stitching Machines

Types of Non-Woven Bag Stitching Machines

Factors Affecting Non Woven Bag Stitching Machine Price

The price of a non woven bag stitching machine can vary significantly based on several factors:

- Automation Level: As mentioned, the level of automation significantly impacts the price. Manual machines are generally the most affordable, while fully automatic machines command higher prices due to their advanced features and increased productivity.

- Brand and Manufacturer: Reputable brands often come with a premium price tag, reflecting their quality and reliability. However, lesser-known manufacturers may offer competitive pricing for comparable machines.

- Features and Specifications: Features like stitching speed, bag size capacity, and the number of needles influence the price. Machines with more advanced features and capabilities will typically cost more.

- Condition (New vs. Used): Purchasing a used machine can be a cost-effective option, but it’s essential to carefully inspect the machine and ensure it’s in good working condition.

Finding the Best Deal

When searching for the best non woven bag stitching machine price, consider the following tips:

- Research and Compare: Thoroughly research different brands, models, and suppliers to compare prices and features. Online marketplaces, industry publications, and trade shows are excellent resources.

- Negotiate: Don’t hesitate to negotiate with suppliers to get the best possible price. Many suppliers are willing to offer discounts, especially for bulk purchases.

- Consider Long-Term Costs: Factor in long-term costs like maintenance, repairs, and energy consumption when evaluating the overall cost of ownership.

From Raw Material to Finished Product: The Non-Woven Bag Production Process

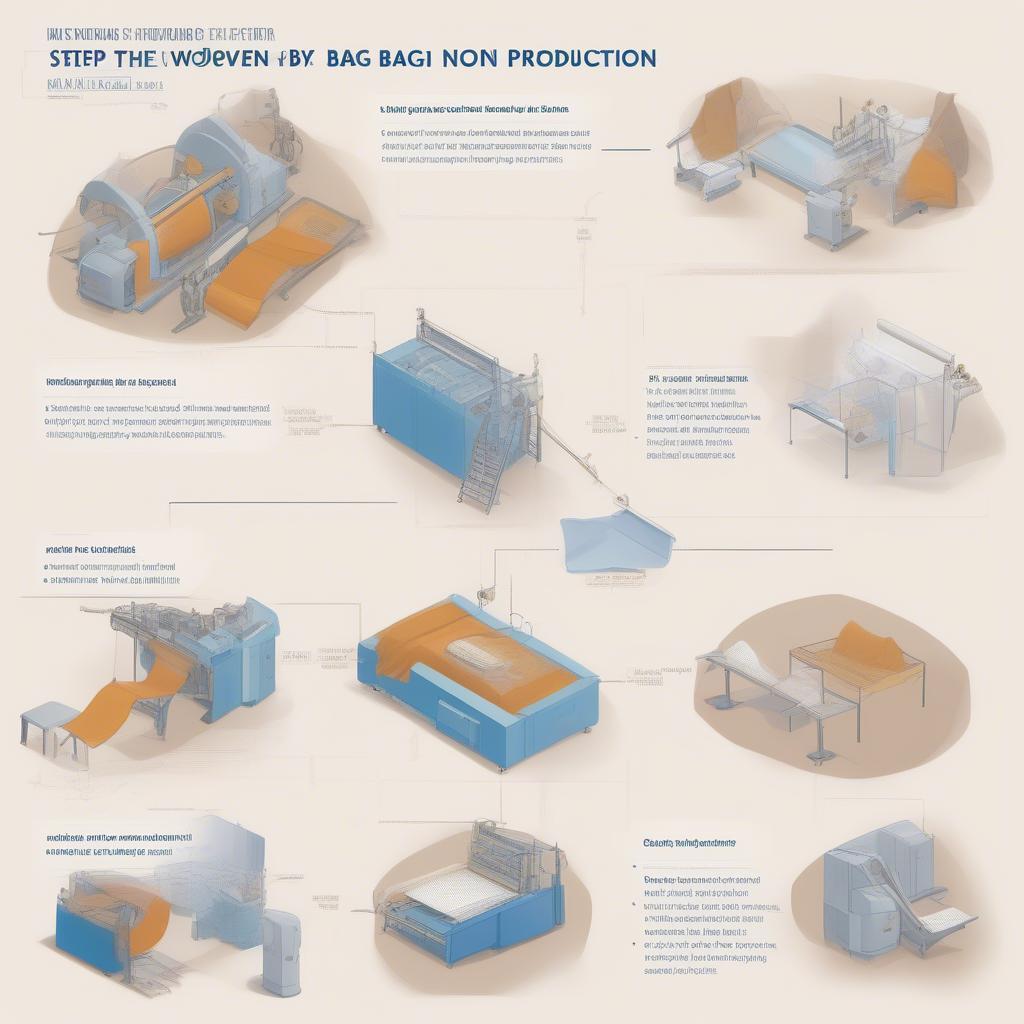

Understanding the non-woven bag production process can further inform your decision-making process when choosing a stitching machine. The process generally involves the following steps:

- Raw Material Selection: Non-woven fabric is typically made from polypropylene (PP) or polyethylene (PE). specification of woven coated bag, pp woven bags 100kg blue

- Fabric Formation: The raw material is processed into a web-like structure using various methods like spunbonding or meltblown.

- Cutting and Shaping: The fabric is cut and shaped into the desired bag dimensions.

- Stitching: The bag panels are sewn together using a non woven bag stitching machine.

- Printing and Finishing: The bags can be printed with logos, designs, or other branding elements. Handles and other accessories are added.

Non-Woven Bag Production Process

Non-Woven Bag Production Process

“Choosing the right stitching machine is crucial for efficient and cost-effective non-woven bag production,” says John Smith, CEO of Stitching Solutions Inc. “Consider your production volume, budget, and desired features to make an informed decision.”

Conclusion

Finding the optimal non woven bag stitching machine price involves careful consideration of various factors, including automation level, brand, features, and long-term costs. By understanding the different machine types, the production process, and utilizing effective research strategies, you can find the perfect machine to meet your specific needs and budget. woven bags bopp

FAQ

- What is the average lifespan of a non-woven bag stitching machine?

- Are there financing options available for purchasing these machines?

- What are the key maintenance requirements for these machines?

- How can I find reliable suppliers of non-woven bag stitching machines?

- What are the common troubleshooting issues with these machines?

- How much space is required to accommodate a non-woven bag stitching machine?

- What safety precautions should be followed when operating these machines?

Need further support? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.