Woven Bag

Finding the Right Non-Woven Filter Bags Manufacturer

Non-woven Filter Bags Manufacturers play a crucial role in various industries, from chemical processing to food and beverage production. Selecting the right manufacturer is paramount to ensuring the efficiency and effectiveness of your filtration processes. This involves understanding the different types of non-woven fabrics, bag designs, and manufacturing capabilities. Choosing a reliable non-woven filter bags manufacturer is essential for achieving optimal filtration results and maintaining high standards of quality. Let’s dive into the world of non-woven filter bags and how to choose the perfect manufacturer for your specific needs.

Understanding Non-Woven Filter Bags

Non-woven filter bags are constructed from synthetic fibers bonded together through thermal, chemical, or mechanical processes. Unlike woven fabrics, which have a defined weave pattern, non-woven materials offer unique filtration properties due to their random fiber orientation. This structure creates a tortuous path for particles, enhancing the bag’s ability to capture fine sediments and contaminants. non-woven filter bags are available in various materials, each offering different chemical resistance, temperature tolerance, and filtration efficiency. Understanding these differences is crucial when choosing a manufacturer.

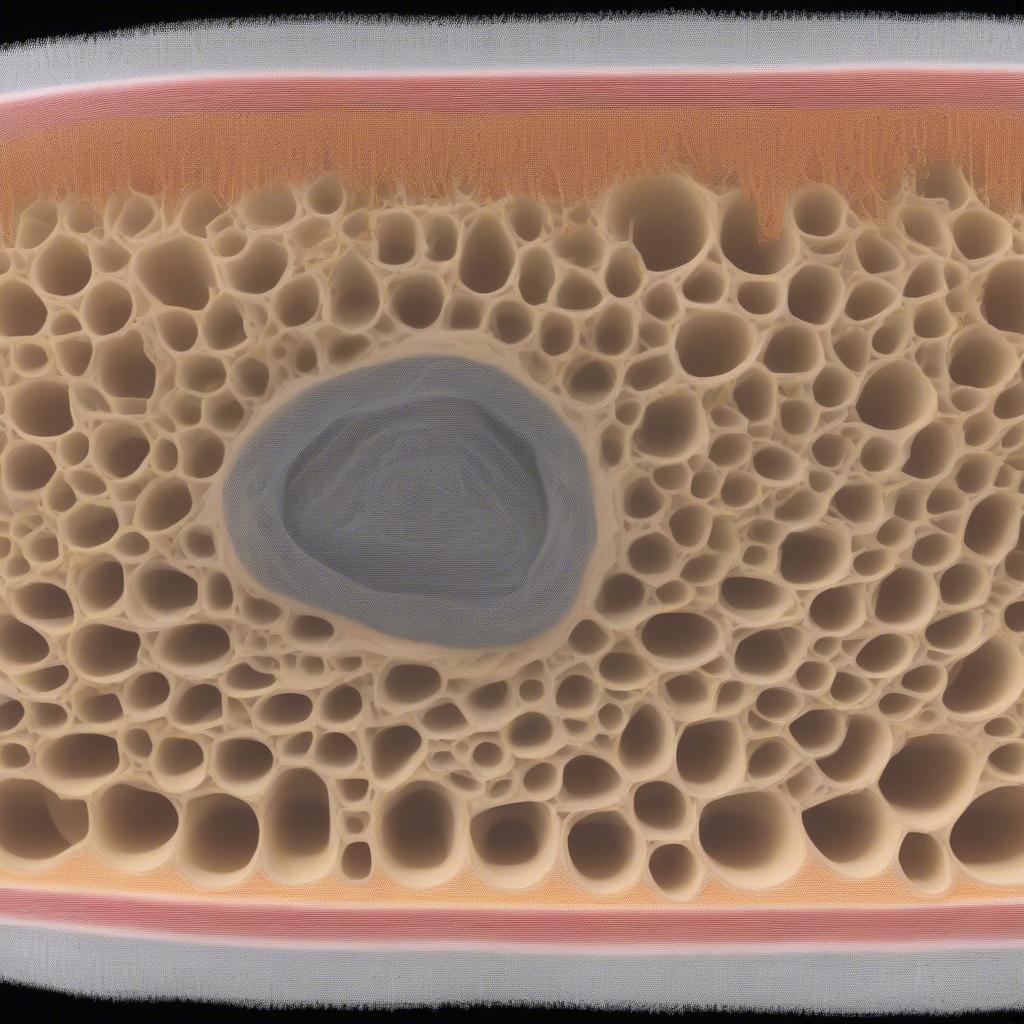

Non-Woven Filter Bag Structure: Cross-sectional view

Non-Woven Filter Bag Structure: Cross-sectional view

Key Considerations When Choosing a Non-Woven Filter Bags Manufacturer

Selecting a non-woven filter bags manufacturer requires careful consideration of several critical factors. These include the manufacturer’s experience, production capabilities, quality control processes, and customer support.

Experience and Expertise

A manufacturer’s experience in the industry speaks volumes about their capability to deliver high-quality products and solutions. Look for manufacturers with a proven track record of working with diverse industries and applications. This experience translates into a deep understanding of filtration requirements and the ability to tailor solutions to meet specific needs.

Production Capabilities

The manufacturing capabilities of a potential supplier are another essential factor. Do they have the necessary equipment and technology to produce the types of filter bags you need? Can they handle your required volume? A robust production infrastructure is vital for meeting deadlines and ensuring consistent product quality.

Non-Woven Filter Bag Production Line

Non-Woven Filter Bag Production Line

Quality Control and Certifications

Stringent quality control measures are indispensable for ensuring that the filter bags meet the required performance standards. Look for manufacturers who adhere to international quality standards and have relevant certifications. This demonstrates their commitment to producing reliable and consistent products. Asking about their testing procedures and quality assurance protocols is a good starting point.

Customer Support and Service

Excellent customer support is crucial for a smooth and hassle-free experience. A responsive and knowledgeable customer service team can provide technical assistance, address inquiries promptly, and offer solutions to any challenges you may encounter.

Benefits of Choosing the Right Manufacturer

Choosing the right non-woven filter bags manufacturer can bring numerous benefits, including:

- Improved Filtration Efficiency: High-quality filter bags ensure optimal removal of contaminants, leading to improved product quality and reduced waste.

- Cost Savings: Durable and reliable filter bags minimize downtime and replacement frequency, resulting in cost savings over the long run.

- Enhanced Product Quality: Effective filtration processes are crucial for maintaining product quality and meeting industry standards.

- Reduced Environmental Impact: Choosing a manufacturer committed to sustainable practices contributes to minimizing the environmental footprint of your operations. Consider manufacturers utilizing recycled materials or implementing environmentally friendly manufacturing processes.

pp spunbond non woven fabric for bags are becoming increasingly popular for filter bags.

Types of Non-Woven Filter Bags

There are various types of non-woven filter bags available, including:

- Needle Felt: Created by mechanically interlocking fibers, offering good strength and filtration efficiency.

- Spunbond: Made from continuous filaments bonded thermally or chemically, providing high strength and durability.

- Meltblown: Composed of extremely fine fibers, ideal for capturing very small particles.

Choosing the right type depends on the specific filtration needs of your application. Consider factors like particle size, chemical compatibility, and temperature requirements.

Different Types of Non-woven Filter Bags

Different Types of Non-woven Filter Bags

Conclusion

Selecting the right non-woven filter bags manufacturer is a crucial decision that can significantly impact the efficiency and effectiveness of your filtration processes. By carefully evaluating a manufacturer’s experience, production capabilities, quality control measures, and customer support, you can ensure you are partnering with a reliable supplier who can meet your specific needs and help you achieve your filtration goals. A well-chosen non-woven filter bags manufacturer is an investment in the long-term success and sustainability of your operations. Consider exploring manufacturers of non woven vest bags for potential synergies.

FAQ

- What are the main types of non-woven fabrics used in filter bags?

- How do I determine the correct micron rating for my filter bags?

- What are the key factors to consider when selecting a filter bag material?

- How often should filter bags be replaced?

- What are the benefits of using non-woven filter bags over other types of filtration media?

- Are there eco-friendly options available for non-woven filter bags?

- What certifications should I look for in a non-woven filter bags manufacturer?

You might also find our articles on china woven bags machine and non-woven bags manufacturer helpful.

Need assistance? Contact our 24/7 customer support team at +84 388 951 999 or visit us in Hanoi, Vietnam or at Tech Avenue, Suite 12, San Francisco, CA 94105, USA.