Woven Bag

Non Woven Geotextile Bags: A Comprehensive Guide

Non Woven Geotextile Bags offer a versatile and eco-friendly solution for various applications, from landscaping and erosion control to construction and agriculture. This guide explores the benefits, uses, and different types of non woven geotextile bags available on the market today.

Understanding Non Woven Geotextile Bags

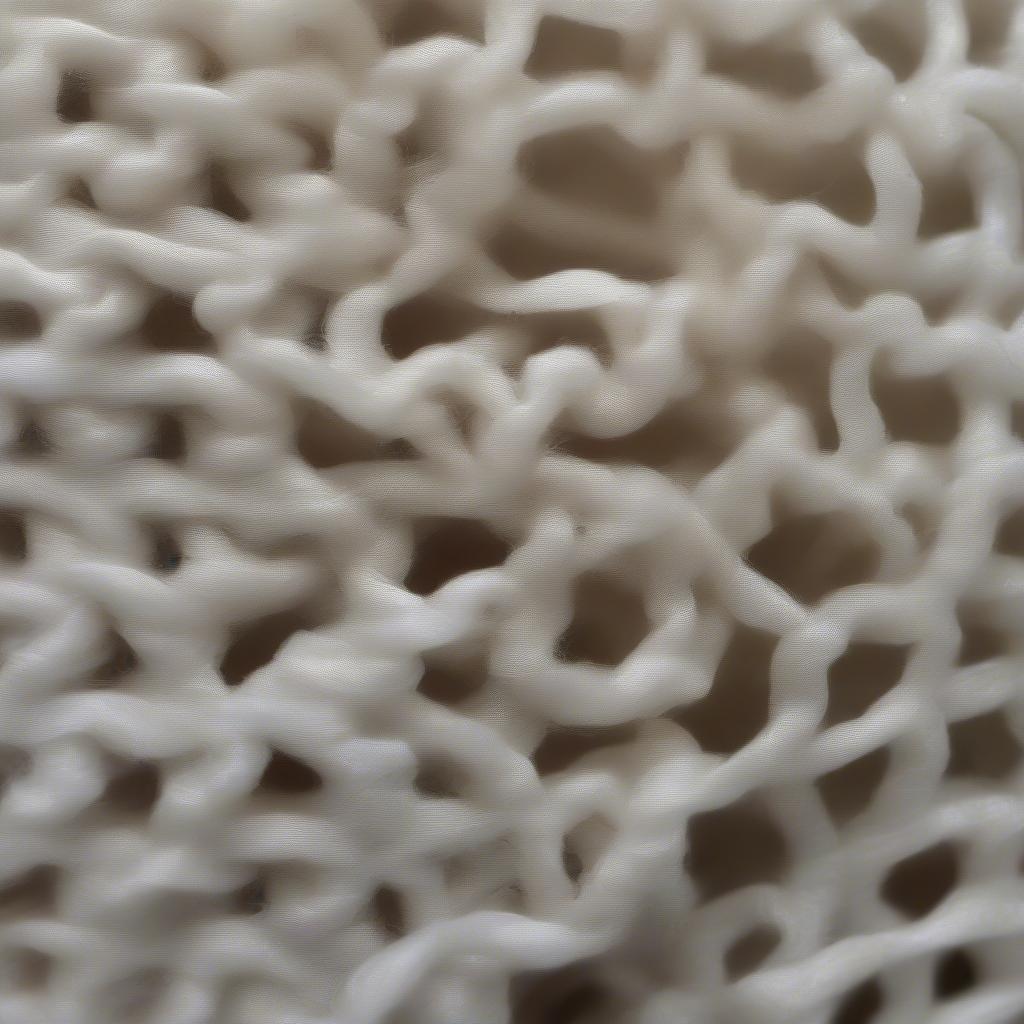

Non woven geotextile bags are constructed from synthetic fibers, typically polypropylene or polyester, which are bonded together through mechanical, thermal, or chemical processes. Unlike woven fabrics, non woven materials do not have a distinct weave pattern, resulting in a more porous and permeable structure. This unique characteristic makes them ideal for applications requiring water filtration and drainage.  Structure of a Non Woven Geotextile Bag

Structure of a Non Woven Geotextile Bag

Advantages of Using Non Woven Geotextile Bags

Non woven geotextile bags provide a range of advantages over traditional materials like burlap or woven fabrics. They are:

- Durable and Long-lasting: Resistant to tearing, punctures, and UV degradation, ensuring extended lifespan in harsh environments.

- Permeable and Breathable: Allows for efficient water drainage and air circulation, preventing waterlogging and promoting healthy plant growth.

- Environmentally Friendly: Many non woven geotextile bags are made from recycled materials and are biodegradable, minimizing environmental impact.

- Cost-Effective: Offers a more affordable solution compared to other erosion control and landscaping methods.

- Easy to Handle and Install: Lightweight and flexible, simplifying transportation and installation processes.

Applications of Non Woven Geotextile Bags

Non woven geotextile bags have diverse applications across various industries. Some common uses include:

- Erosion Control: Stabilizing slopes, riverbanks, and shorelines, preventing soil erosion and protecting infrastructure.

Non Woven Geotextile Bags for Erosion Control

Non Woven Geotextile Bags for Erosion Control - Landscaping and Gardening: Creating raised garden beds, retaining walls, and drainage systems, improving soil stability and water management.

- Construction: Used for temporary dewatering, sediment control, and soil stabilization during construction projects.

- Agriculture: Protecting crops from frost, pests, and weeds, while promoting healthy root development.

- Flood Control: Creating temporary barriers and diverting floodwaters to protect properties and infrastructure.

Types of Non Woven Geotextile Bags

Non woven geotextile bags are available in different sizes, weights, and materials to suit specific project requirements.

- Polypropylene Bags: Known for their strength, durability, and resistance to chemicals and UV degradation.

- Polyester Bags: Offers excellent resistance to abrasion and tearing, suitable for applications requiring high strength and durability.

- Recycled Material Bags: Eco-friendly option made from recycled plastics, reducing environmental impact.

Choosing the Right Non Woven Geotextile Bag

Selecting the appropriate non woven geotextile bag depends on several factors, including:

- Project Requirements: Consider the specific application and the level of strength, permeability, and durability required.

- Environmental Conditions: Evaluate factors such as soil type, water flow, and UV exposure to ensure the bag can withstand the environment.

- Budget: Compare prices and choose a bag that meets project requirements within budget constraints.

How are Non Woven Geotextile Bags Made?

Non woven geotextile bags are typically manufactured using a spunbond or needlepunch process. The spunbond process involves extruding molten polymer fibers and bonding them together using heat or pressure. Needlepunching involves mechanically interlocking fibers using barbed needles.  Non Woven Geotextile Bag Manufacturing Process

Non Woven Geotextile Bag Manufacturing Process

Conclusion

Non woven geotextile bags are a versatile and sustainable solution for a wide range of applications. Their durability, permeability, and cost-effectiveness make them an ideal choice for erosion control, landscaping, construction, and agriculture. By understanding the different types and applications of non woven geotextile bags, you can make an informed decision and choose the right product for your specific needs.

FAQs

-

Are non woven geotextile bags biodegradable?

Some are, particularly those made from natural fibers or biodegradable polymers. Check manufacturer specifications. -

How long do non woven geotextile bags last?

Lifespan varies depending on material and environmental conditions, typically several years. -

Can I reuse non woven geotextile bags?

Yes, in many cases they can be reused for similar applications. -

What is the difference between woven and non woven geotextile bags?

Woven bags have a distinct weave, making them less permeable, while non woven bags are more porous. -

Are non woven geotextile bags safe for plants?

Yes, they are generally safe and can even promote healthy root development. -

What sizes are non woven geotextile bags available in?

Various sizes are available depending on the application. -

Where can I buy non woven geotextile bags?

They are available from various suppliers, both online and in retail stores.

When you need support, please contact our Hotline: +84 388 951 999, address: Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.