Woven Bag

Non Woven Rice Bags: A Comprehensive Guide

Non-woven rice bags have become a staple in the rice industry, offering a practical and cost-effective solution for packaging and transportation. From their manufacturing process to their various applications, this guide will delve into the world of non-woven rice bags, exploring their benefits and addressing common questions.

Understanding Non-Woven Rice Bags

Non-woven rice bags are made from polypropylene (PP) or polyethylene (PE) fibers, bonded together through mechanical, thermal, or chemical processes. Unlike woven bags, which are created by interlacing yarns, non-woven bags are formed by layering and bonding fibers, resulting in a fabric-like material. This structure gives non-woven rice bags several advantages, including durability, breathability, and resistance to tearing. They are also lightweight and easily customizable, making them ideal for branding and printing.

Stack of Non-Woven Rice Bags

Stack of Non-Woven Rice Bags

Advantages of Using Non-Woven Rice Bags

Why choose non-woven bags for rice packaging? Several key benefits make them a preferred option:

- Strength and Durability: Non-woven bags can withstand the weight and pressure of stacked rice bags, minimizing the risk of tearing during handling and transportation.

- Breathability: The porous nature of non-woven fabric allows for air circulation, preventing moisture buildup and preserving the quality of the rice.

- Cost-Effectiveness: Compared to traditional packaging options, non-woven bags offer a more affordable solution without compromising on quality.

- Customizability: Non-woven bags can be easily printed with branding, logos, and product information, enhancing brand visibility.

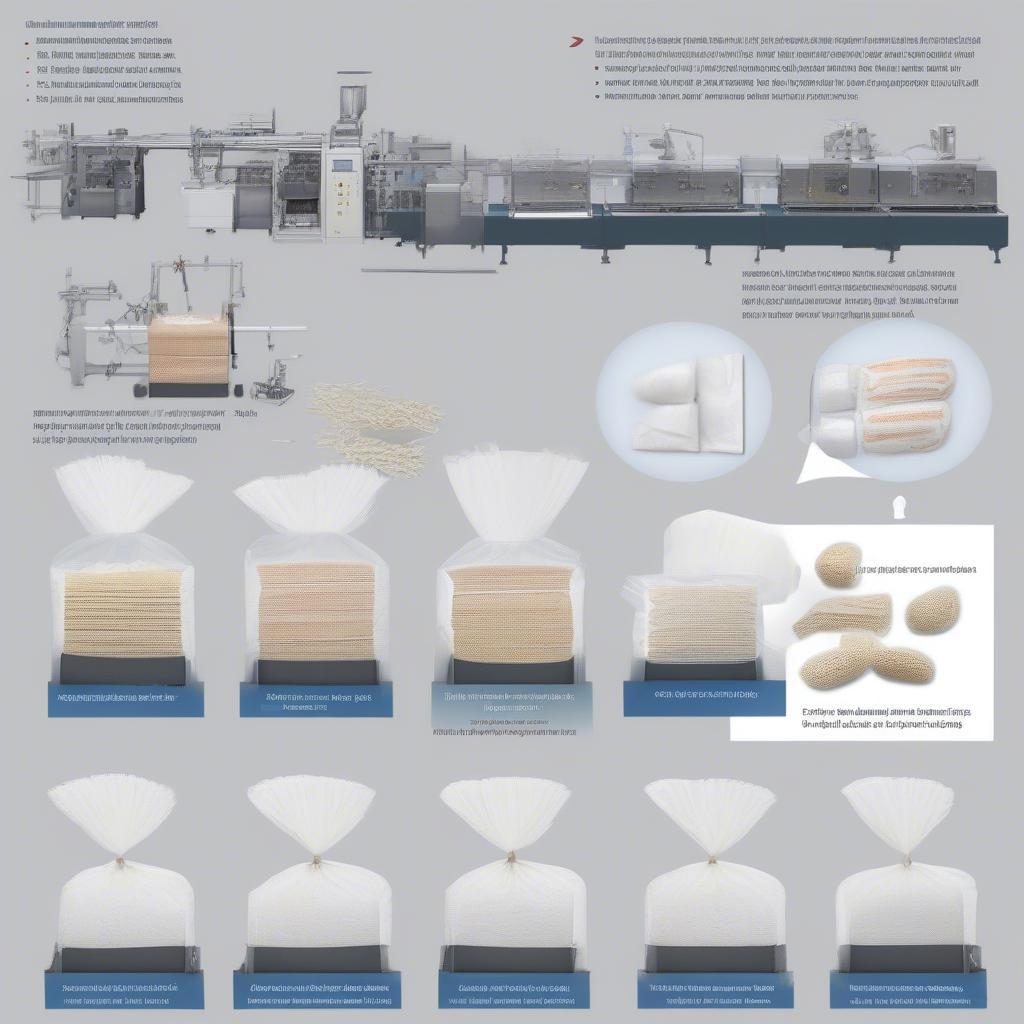

Exploring the Manufacturing Process of Non-Woven Rice Bags

The production of non-woven rice bags involves several steps:

- Fiber Preparation: Polypropylene or polyethylene pellets are melted and extruded into fine fibers.

- Web Formation: The fibers are laid out to form a web, which is the basis of the non-woven fabric.

- Bonding: The web is bonded together using methods like heat bonding, chemical bonding, or needle punching.

- Cutting and Sewing: The bonded fabric is cut and sewn into the desired bag shape and size.

- Printing (Optional): The bags can be printed with customized designs and information.

Non-Woven Rice Bag Manufacturing Process

Non-Woven Rice Bag Manufacturing Process

Want to know more about suppliers in India? Check out non woven rice bags suppliers in india.

Non-Woven Rice Bags vs. Traditional Packaging

Compared to traditional jute or paper bags, non-woven rice bags offer significant advantages:

- Moisture Resistance: Non-woven bags are less susceptible to moisture damage, ensuring the rice stays dry and free from mold.

- Pest Resistance: The synthetic fibers used in non-woven bags are less attractive to pests, further protecting the rice.

- Longer Shelf Life: These bags contribute to a longer shelf life for the rice by providing a protective barrier against environmental factors.

“Non-woven rice bags are a game-changer for the rice industry. Their durability and cost-effectiveness are unmatched.” – Dr. Anya Sharma, Agricultural Economist.

Are you looking for manufacturers in Hyderabad? non woven rice bags manufacturer in hyderabad provides valuable information.

Different Types of Non-Woven Rice Bags

Non-woven rice bags are available in various sizes and designs to accommodate different rice quantities and branding requirements. Some common types include:

- Drawstring Bags: These bags feature a drawstring closure for easy sealing and handling.

- Gusseted Bags: Gusseted bags have expandable sides, allowing them to hold larger volumes of rice.

- Printed Bags: Custom printed bags provide a platform for branding and product information.

Variety of Non-Woven Rice Bags

Variety of Non-Woven Rice Bags

Interested in the manufacturing machinery? non woven rice bags manufacturing machine offers a detailed overview. For those interested in pricing in India, non woven rice bag making machine price in india is a valuable resource. And for printing, don’t miss non woven rice bag printing machine.

Conclusion

Non-woven rice bags are a modern and efficient packaging solution for the rice industry. Their durability, breathability, and cost-effectiveness make them a superior choice compared to traditional packaging. From protecting the rice during transportation to enhancing brand visibility, non-woven rice bags offer a range of benefits that contribute to the overall success of the rice supply chain.

“The shift to non-woven bags has significantly improved our efficiency and reduced packaging costs.” – Rajesh Kumar, Rice Mill Owner.

When you need support, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.