Woven Bag

Non-Woven Shopping Bag Making Machine: A Comprehensive Guide

Non-woven Shopping Bag Making Machines are revolutionizing the packaging industry. These machines offer a cost-effective and efficient way to produce eco-friendly shopping bags, meeting the growing demand for sustainable alternatives. This guide will delve into the intricacies of these machines, exploring their types, benefits, and the factors to consider when choosing one for your business. pp woven shopping grocery bag

Understanding the Non-Woven Bag Making Process

The process of creating non-woven bags involves several steps, from feeding the raw material to the finished product. Non-woven fabric is created by bonding fibers together through heat, chemical, or mechanical methods. This fabric is then fed into the non-woven shopping bag making machine, where it is cut, sealed, and shaped into the desired bag design. Understanding these stages is crucial for optimizing production efficiency and ensuring high-quality output.

Key Components of a Non-Woven Bag Making Machine

Several key components contribute to the seamless operation of a non-woven shopping bag making machine. These include:

- Unwinding Unit: This unit feeds the non-woven fabric roll into the machine.

- Cutting Unit: Precisely cuts the fabric according to the desired bag dimensions.

- Sealing Unit: Uses heat or ultrasonic waves to create strong and durable seals.

- Handle Attaching Unit: Automatically attaches handles to the bags.

- Stacking Unit: Neatly stacks the finished bags for easy collection and packaging.

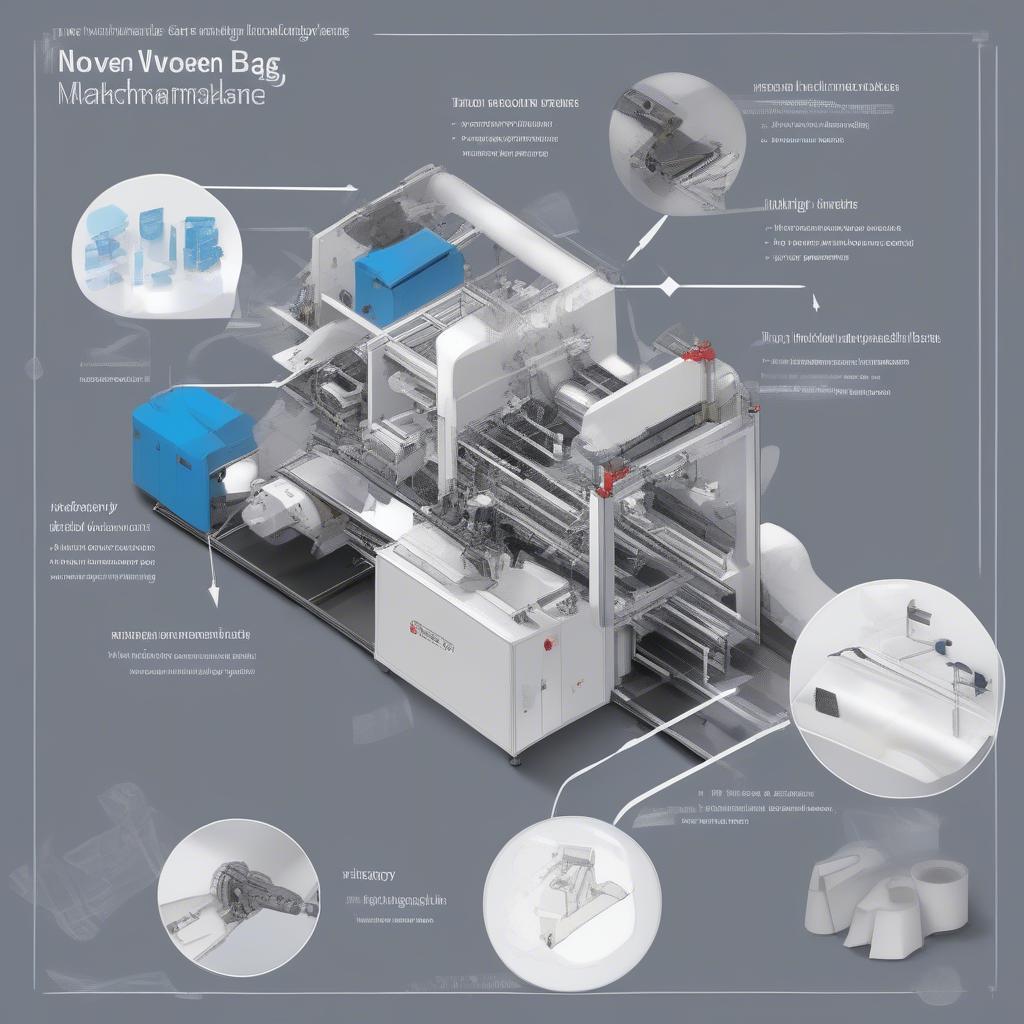

Non-Woven Bag Making Machine Components Diagram

Non-Woven Bag Making Machine Components Diagram

Types of Non-Woven Shopping Bag Making Machines

Various types of non-woven shopping bag making machines cater to different production needs and bag styles. These include:

- Fully Automatic Machines: Offer high-speed production and minimal manual intervention, ideal for large-scale operations.

- Semi-Automatic Machines: Require some manual input, offering a balance between cost and output.

- Specialized Machines: Designed for specific bag types, such as box bags, D-cut bags, or U-cut bags.

Choosing the Right Non-Woven Shopping Bag Making Machine

Selecting the appropriate machine requires careful consideration of several factors. These factors include:

- Production Capacity: Assess your required output volume to determine the necessary machine speed and automation level.

- Bag Styles: Consider the types of bags you intend to produce, as different machines specialize in different designs.

- Budget: Balance your investment with your production needs and expected return on investment.

- Maintenance and Support: Ensure the manufacturer provides adequate after-sales service and readily available spare parts.

“Investing in the right non-woven bag making machine can significantly impact your business’s profitability and sustainability efforts,” says John Miller, a leading packaging industry consultant. He emphasizes the importance of thorough research and careful planning before making a purchase.

non woven bag manufacturer in bangladesh

Benefits of Using a Non-Woven Shopping Bag Making Machine

Utilizing a non-woven shopping bag making machine offers numerous advantages:

- Increased Efficiency: Automates the bag-making process, reducing manual labor and increasing output.

- Cost Savings: Minimizes material waste and optimizes production costs.

- Consistent Quality: Ensures uniform bag size, shape, and sealing, enhancing product presentation.

- Versatility: Can produce a wide range of bag styles and sizes.

- Eco-Friendliness: Promotes the use of sustainable and recyclable non-woven materials.

Variety of Non-Woven Bags

Variety of Non-Woven Bags

Future Trends in Non-Woven Bag Making Technology

The non-woven bag making industry continues to evolve, driven by advancements in automation, material science, and consumer demand. Emerging trends include:

- Smart Manufacturing: Integrating sensors and data analytics to optimize machine performance and predictive maintenance.

- Biodegradable Materials: Developing and utilizing biodegradable non-woven fabrics for enhanced sustainability.

- Customized Printing Solutions: Offering advanced printing technologies for personalized bag designs and branding.

“The future of non-woven bag making lies in innovation and sustainability,” explains Sarah Lee, a materials engineer specializing in non-woven fabrics. She anticipates further advancements in biodegradable materials and intelligent manufacturing processes.

laminated pp non-woven storage bag

Conclusion

Non-woven shopping bag making machines are essential for businesses seeking to efficiently produce eco-friendly packaging solutions. By understanding the various machine types, their benefits, and the factors to consider when making a purchase, businesses can optimize their production processes and contribute to a more sustainable future. Choosing the right non-woven shopping bag making machine is a crucial investment for any business in the packaging industry.

non woven box bag making machine made in china

Modern Non-Woven Bag Making Facility

Modern Non-Woven Bag Making Facility

When you need support, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.