Woven Bag

OEM Woven Bag: Your Ultimate Guide to Sourcing and Selecting the Perfect Woven Bag

Oem Woven Bags are increasingly popular, offering a unique blend of style, durability, and eco-consciousness. Whether you’re a business looking for custom-branded merchandise or an individual seeking a stylish and sustainable accessory, understanding the world of OEM woven bags is crucial. This guide explores everything from material selection to manufacturing processes, empowering you to make informed decisions. kate spade woven beach bag

Understanding OEM Woven Bags: Materials, Manufacturing, and More

OEM, or Original Equipment Manufacturer, refers to a company that manufactures products that are then branded and sold by another company. In the context of woven bags, this means you can work with a manufacturer to create custom bags tailored to your specific needs.

Choosing the Right Material for Your OEM Woven Bag

Choosing the right material is paramount. Popular choices include:

- Rattan: Known for its strength and flexibility, rattan offers a classic, natural look.

- Wicker: A versatile material that can be woven into various patterns and designs, wicker is lightweight and durable.

- Seagrass: A sustainable and rapidly renewable resource, seagrass adds a unique texture and aesthetic appeal.

- Bamboo: Another eco-friendly option, bamboo is strong, lightweight, and known for its fast growth rate.

OEM Woven Bag Materials: Rattan, Wicker, Seagrass, and Bamboo

OEM Woven Bag Materials: Rattan, Wicker, Seagrass, and Bamboo

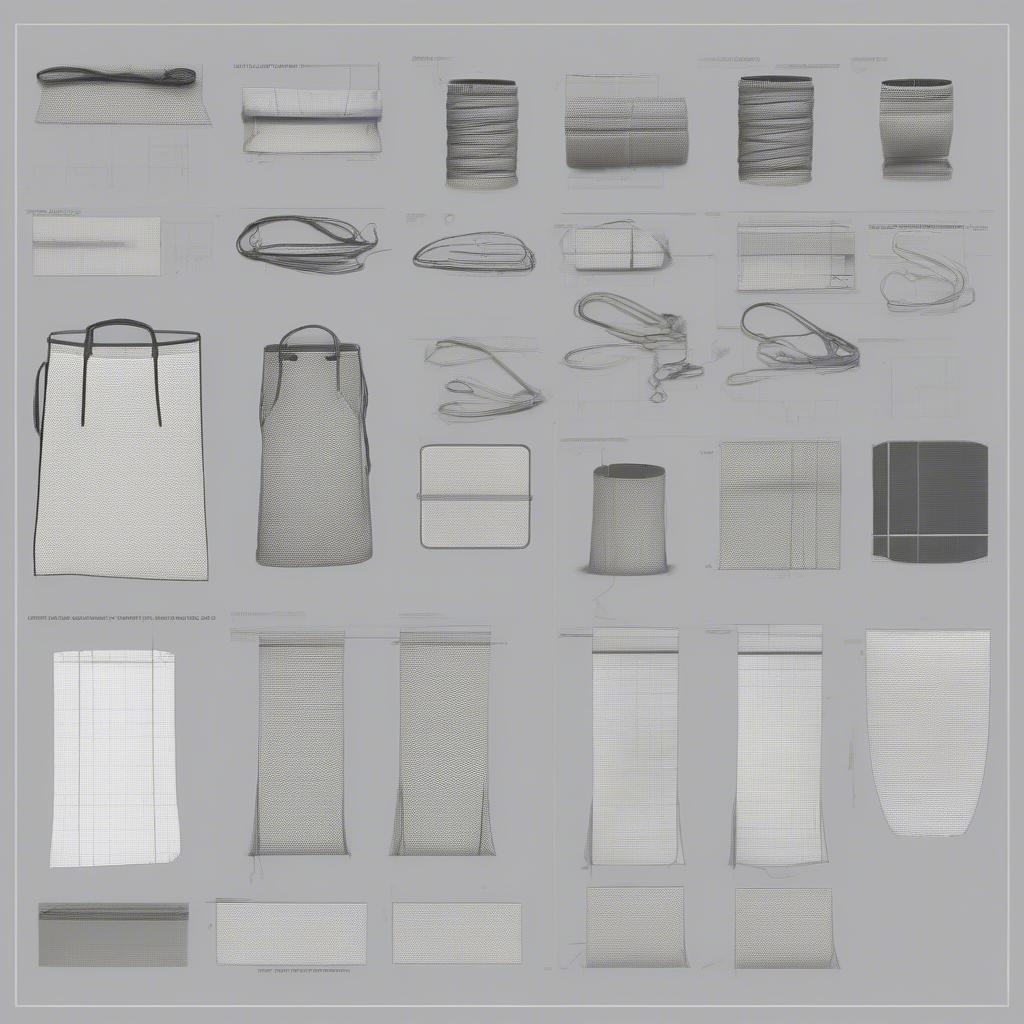

The Manufacturing Process: From Design to Delivery

The manufacturing process for OEM woven bags typically involves the following steps:

- Design and Prototyping: Collaborate with the manufacturer to finalize the design, including size, shape, and features. A prototype is usually created for approval before mass production.

- Material Sourcing: The manufacturer sources the chosen materials, ensuring quality and sustainability.

- Weaving: Skilled artisans meticulously weave the materials into the desired bag shape.

- Finishing: Handles, linings, and other details are added to complete the bag.

- Quality Control: Each bag is inspected to ensure it meets the required standards.

- Packaging and Shipping: The finished bags are packaged and shipped to the client.

Benefits of Choosing OEM Woven Bags

OEM woven bags offer a plethora of advantages:

- Customization: Create unique bags that reflect your brand identity.

- Quality Control: Work directly with the manufacturer to ensure high-quality materials and craftsmanship.

- Cost-Effectiveness: OEM production can be cost-effective, especially for large orders.

- Sustainability: Many woven materials are eco-friendly and sustainable.

What to Consider When Sourcing an OEM Woven Bag Manufacturer

kate spade nadine woven spade medium flap shoulder bag

When selecting an OEM woven bag manufacturer, consider the following:

- Experience and Expertise: Choose a manufacturer with a proven track record in producing high-quality woven bags.

- Material Sourcing: Inquire about their material sourcing practices and ensure they align with your sustainability goals.

- Production Capacity: Ensure they can handle your order volume and meet your deadlines.

- Communication and Collaboration: Effective communication is essential for a smooth and successful partnership.

OEM Woven Bag Manufacturing Process: Design, Weaving, Finishing

OEM Woven Bag Manufacturing Process: Design, Weaving, Finishing

How are OEM Woven Bags Different from Ready-Made Bags?

OEM woven bags offer unparalleled customization options compared to ready-made bags. You have control over every aspect, from the material and design to the size and features.

Why Choose an OEM Woven Bag for Your Business?

OEM woven bags can be a powerful marketing tool, allowing you to create branded merchandise that stands out. They also offer a sustainable and stylish alternative to traditional promotional items. kate spade woven lemon bag

“OEM woven bags are a fantastic way to showcase your brand’s commitment to sustainability and style,” says Amelia Reed, a sustainable fashion consultant. “They’re a unique and memorable promotional item that customers will appreciate.”

Finding the Perfect OEM Woven Bag: Tips and Tricks

kate spade multi color woven nylon tote bag

- Research and Compare: Thoroughly research different manufacturers and compare their offerings.

- Request Samples: Ask for samples to assess the quality of the materials and craftsmanship.

- Negotiate Pricing: Don’t hesitate to negotiate pricing, especially for large orders.

Selecting the Perfect OEM Woven Bag: Research, Samples, Negotiation

Selecting the Perfect OEM Woven Bag: Research, Samples, Negotiation

Conclusion: OEM Woven Bags – A Sustainable and Stylish Choice

OEM woven bags offer a unique blend of style, durability, and sustainability. By carefully considering the factors outlined in this guide, you can source the perfect oem woven bag that meets your specific needs and reflects your brand identity. kate spade woven quilt bag

FAQ

- What is the minimum order quantity for OEM woven bags?

- What are the typical lead times for OEM woven bag production?

- Can I request custom designs for my OEM woven bags?

- What are the different printing options available for branding OEM woven bags?

- What are the care instructions for woven bags?

- Are OEM woven bags biodegradable?

- How do I choose the right size woven bag for my needs?

Need assistance? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.