Woven Bag

PP Tubular Woven Laminated Bags: A Comprehensive Guide

Pp Tubular Woven Laminated Bags are a versatile and robust packaging solution, ideal for various industries. From construction materials to agricultural products, these bags offer durability, weather resistance, and cost-effectiveness. Let’s delve into the world of PP tubular woven laminated bags and explore their unique properties, applications, and benefits.

Understanding PP Tubular Woven Laminated Bags

PP tubular woven laminated bags are constructed from polypropylene (PP) fabric woven into a tubular shape. This tubular structure is then laminated with a layer of polypropylene film, enhancing the bag’s strength, moisture resistance, and overall performance. This construction distinguishes them from traditional woven bags, providing superior protection for the contents within.

What Makes PP Tubular Woven Bags Unique?

- Durability: The woven construction, coupled with lamination, provides exceptional strength and tear resistance. These bags can withstand rough handling, stacking, and transportation stresses.

- Moisture Resistance: The lamination acts as a barrier against moisture, protecting the contents from rain, humidity, and other environmental factors. This is particularly crucial for hygroscopic materials.

- Customization: PP tubular woven laminated bags are highly customizable. They can be printed with logos, branding, and product information, turning them into effective marketing tools.

- Cost-Effectiveness: Compared to other packaging options like paper or jute bags, PP tubular woven laminated bags offer a more economical solution, especially for bulk goods.

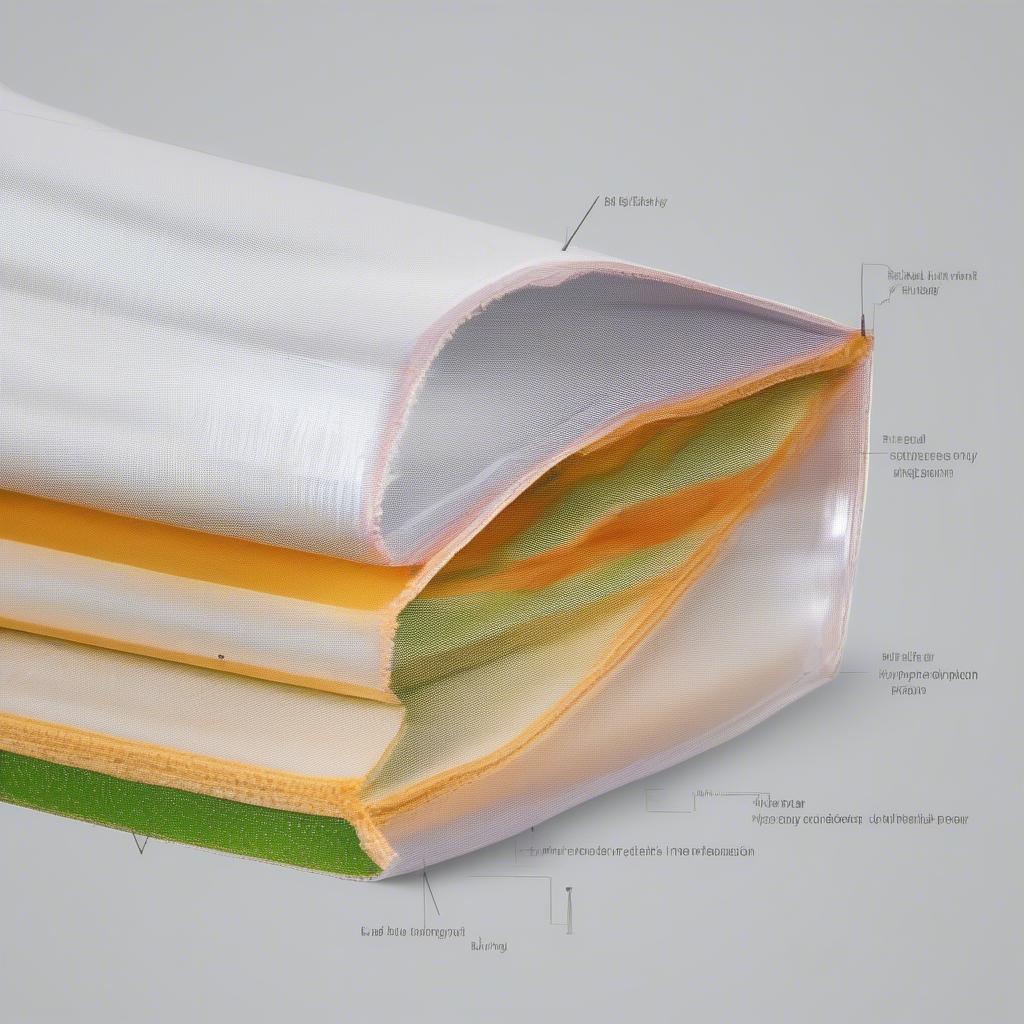

PP Tubular Woven Laminated Bag Structure Diagram

PP Tubular Woven Laminated Bag Structure Diagram

Applications of PP Tubular Woven Laminated Bags

These versatile bags find applications across a wide range of industries:

- Agriculture: For storing and transporting grains, fertilizers, seeds, and animal feed.

- Construction: Packaging cement, sand, gravel, and other building materials.

- Chemicals: Containing and transporting various chemicals, powders, and granules.

- Food Industry: Packaging sugar, flour, rice, and other dry food products. (Food-grade variants are used in this industry).

Choosing the Right PP Tubular Woven Laminated Bag

Selecting the right bag depends on several factors:

- Size and Capacity: Bags come in various sizes to accommodate different product volumes.

- Denier: Denier refers to the thickness of the yarn. Higher denier indicates a stronger bag.

- Lamination Type: Different lamination options offer varying levels of moisture and UV protection.

- Printing Requirements: Consider whether you need custom printing for branding or product information.

PP Tubular Woven Laminated Bags in Various Sizes

PP Tubular Woven Laminated Bags in Various Sizes

“Choosing the right bag is about understanding your specific needs,” says John Miller, Senior Packaging Consultant at Packaging Solutions Inc. “Factors like the product being packaged, storage conditions, and transportation methods all play a role in the decision-making process.”

Advantages of Using PP Tubular Woven Laminated Bags

- Reusable and Recyclable: These bags can be reused multiple times, reducing environmental impact. They are also recyclable, further contributing to sustainability.

- Lightweight: Their lightweight nature reduces shipping costs and makes them easy to handle.

- UV Protection: Certain lamination options offer protection from UV rays, preventing product degradation.

- Easy Storage: When empty, these bags can be folded flat, minimizing storage space requirements.

Why Choose PP Over Other Materials?

PP offers several advantages over other materials like jute or paper:

- Higher Strength: PP is significantly stronger and more resistant to tearing than jute or paper.

- Better Moisture Resistance: PP offers superior moisture protection, preventing spoilage and damage.

- Longer Lifespan: PP bags are more durable and have a longer lifespan than bags made from other materials.

PP Tubular Woven Laminated Bag Applications

PP Tubular Woven Laminated Bag Applications

“The durability and cost-effectiveness of PP tubular woven laminated bags make them a popular choice for businesses seeking reliable packaging solutions,” adds Maria Sanchez, Lead Packaging Engineer at Global Packaging Solutions. “Their adaptability to various industries and customization options further enhance their appeal.”

Conclusion

PP tubular woven laminated bags offer a durable, cost-effective, and versatile packaging solution for numerous industries. Their strength, moisture resistance, and customizability make them a preferred choice for businesses seeking reliable and efficient packaging. By understanding the various options and selecting the right bag for your specific needs, you can optimize your packaging process and protect your valuable products.

FAQ

- Are PP tubular woven laminated bags recyclable? Yes, these bags are recyclable, contributing to environmental sustainability.

- What is the difference between woven and laminated bags? Woven bags are made from woven fabric, while laminated bags have an additional layer of film for enhanced protection.

- Can these bags be custom printed? Yes, they can be printed with logos, branding, and other information.

- What are the common sizes available? Sizes vary depending on the manufacturer, but a wide range of sizes is available to accommodate various product volumes.

- What is the denier of a woven bag? Denier refers to the thickness of the yarn used in the bag’s construction. Higher denier indicates a stronger bag.

Scenarios:

- Scenario 1: A cement manufacturer needs robust bags for transporting cement. PP tubular woven laminated bags are ideal due to their strength and moisture resistance.

- Scenario 2: A farmer needs to store and transport grains. These bags offer a cost-effective and durable solution for protecting the grains from moisture and pests.

- Scenario 3: A chemical company needs to package chemicals safely and efficiently. PP tubular woven laminated bags provide the necessary strength and protection for handling potentially hazardous materials.

Related Articles:

- Choosing the Right Packaging for Your Business

- The Benefits of Sustainable Packaging

- Understanding Different Types of Woven Bags

If you need assistance, please contact our 24/7 customer service team at Hotline: +84 388 951 999, Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA.