Woven Bag

PP Woven Bag Extruder Machine Factory: A Comprehensive Guide

PP woven bag extruder machine factories are the backbone of the woven packaging industry. They provide the crucial equipment that transforms polypropylene pellets into the versatile woven bags used for everything from agricultural products to construction materials. Understanding the intricacies of these factories, their machinery, and the processes involved is crucial for anyone involved in the packaging sector.

Overview of a PP Woven Bag Extruder Machine Factory

Overview of a PP Woven Bag Extruder Machine Factory

Understanding the PP Woven Bag Extruder Machine

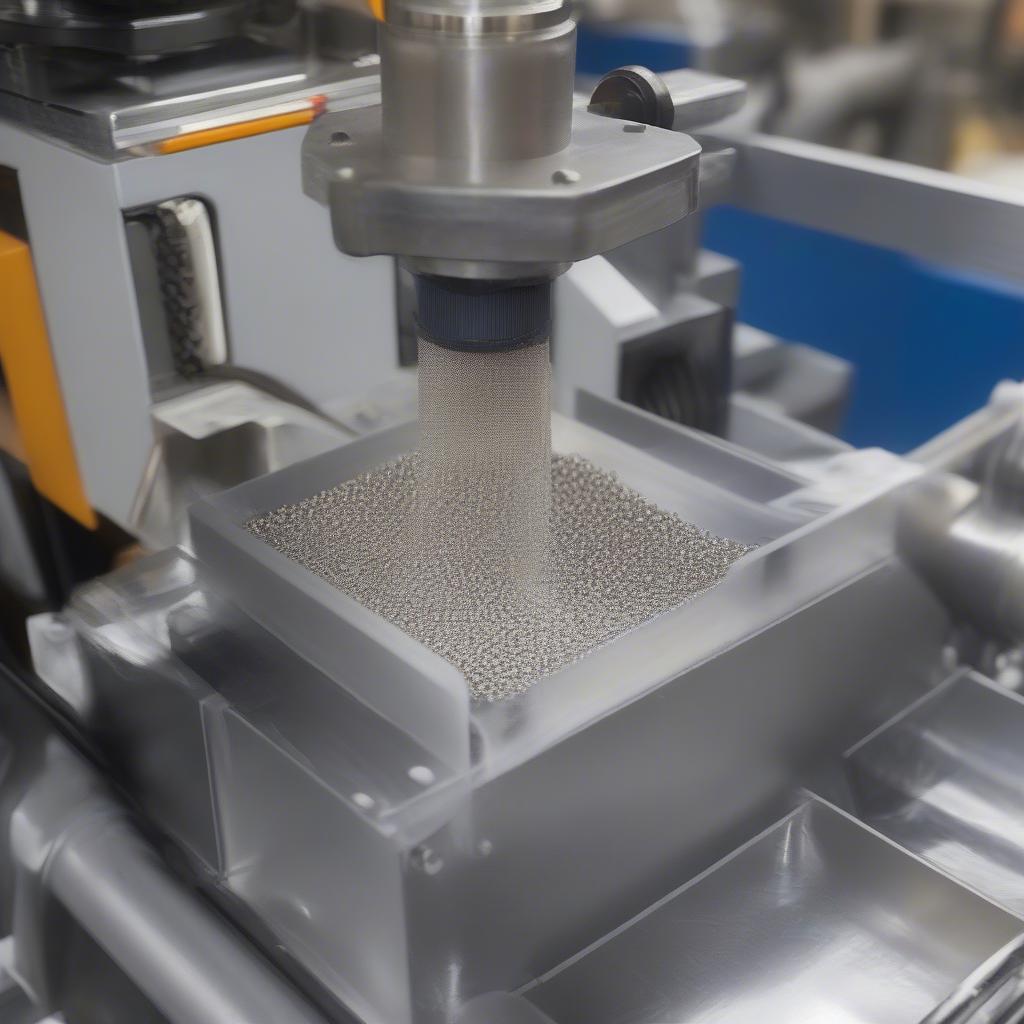

At the heart of any Pp Woven Bag Extruder Machine Factory lies the extruder itself. This sophisticated piece of machinery melts polypropylene pellets and extrudes them into thin, flat strands. These strands are then cooled and stretched, forming the basis of the woven fabric. The quality of the extruder directly impacts the quality of the final woven bag, influencing factors like strength, durability, and printability. Different types of extruders cater to varying production needs, from small-scale operations to high-volume manufacturing.

Lia numa bags woven from these factories often find their way into various industries.

Detailed View of the PP Woven Bag Extrusion Process

Detailed View of the PP Woven Bag Extrusion Process

Key Components of the Extruder Machine

- Hopper: This is where the polypropylene pellets are fed into the machine.

- Barrel and Screw: The barrel houses the rotating screw, which melts and conveys the plastic forward.

- Die: This shapes the molten plastic into flat strands.

- Cooling System: Rapidly cools the extruded strands to solidify them.

- Stretching Unit: Stretches the cooled strands to enhance their strength and properties.

Inside the PP Woven Bag Extruder Machine Factory

A typical pp woven bag extruder machine factory encompasses more than just the extruder. It’s a complex ecosystem of interconnected processes, from raw material handling to quality control.

Raw Material Handling

Efficient raw material handling is essential for smooth operations. Factories typically have dedicated storage areas for polypropylene pellets and systems for transporting them to the extruder hopper.

Weaving Process

After extrusion, the strands are woven into fabric using specialized circular looms. These looms interlace the strands in a specific pattern, determining the final structure and strength of the woven bag.

Cutting and Stitching

The woven fabric is then cut and stitched into bags of various sizes and shapes. This process often involves automated machinery for high-speed production.

Printing and Finishing

Many factories offer printing and finishing services, allowing customization of the woven bags with logos, branding, and other designs. This adds value and enhances the marketability of the finished product.

Choosing the Right PP Woven Bag Extruder Machine Factory

Selecting the right factory is a crucial decision for businesses looking to invest in woven packaging.

Factors to Consider:

- Production Capacity: Choose a factory that can meet your volume requirements.

- Quality Control: Look for factories with robust quality control measures.

- Technology and Equipment: Ensure the factory uses modern and efficient machinery.

- Experience and Expertise: Consider the factory’s experience and reputation in the industry.

- Customer Service and Support: Opt for a factory that offers reliable customer service and technical support.

“A reputable PP woven bag extruder machine factory invests heavily in advanced technology and rigorous quality control processes,” says John Miller, a seasoned packaging engineer. “This ensures the production of high-quality woven bags that meet the demanding requirements of various industries.”

Quality Control Inspection at a PP Woven Bag Factory

Quality Control Inspection at a PP Woven Bag Factory

Conclusion

The pp woven bag extruder machine factory plays a vital role in providing sustainable and versatile packaging solutions. Understanding the complexities of these factories, their machinery, and the entire production process is essential for making informed decisions and maximizing the benefits of woven packaging. Choosing the right factory partner is a key step towards achieving your packaging goals.

FAQ

- What types of plastic can be used in a pp woven bag extruder machine?

- How does the speed of the extruder affect the quality of the woven fabric?

- What are the different weaving patterns used in circular looms?

- What are the typical maintenance requirements for an extruder machine?

- What are the environmental considerations for pp woven bag production?

- What are the common quality control checks performed in a pp woven bag factory?

- What are the different types of printing methods used for customizing woven bags?

“The future of woven packaging relies on innovation and sustainability,” adds Maria Garcia, a leading materials scientist. “PP woven bag extruder machine factories are constantly evolving to meet these challenges, developing new technologies and processes to minimize environmental impact and enhance the performance of woven bags.”

Need help finding the right pp woven bag extruder machine factory? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. Our 24/7 customer service team is ready to assist you.