Woven Bag

Optimizing Your PP Woven Bag Granulation Line for Efficiency

A Pp Woven Bag Granulation Line is essential for recycling and reusing plastic materials, contributing to a circular economy. Understanding how to optimize your line ensures maximum output and minimal waste, crucial for businesses focused on sustainability and profitability. Let’s explore the intricacies of PP woven bag granulation and how to improve its performance.

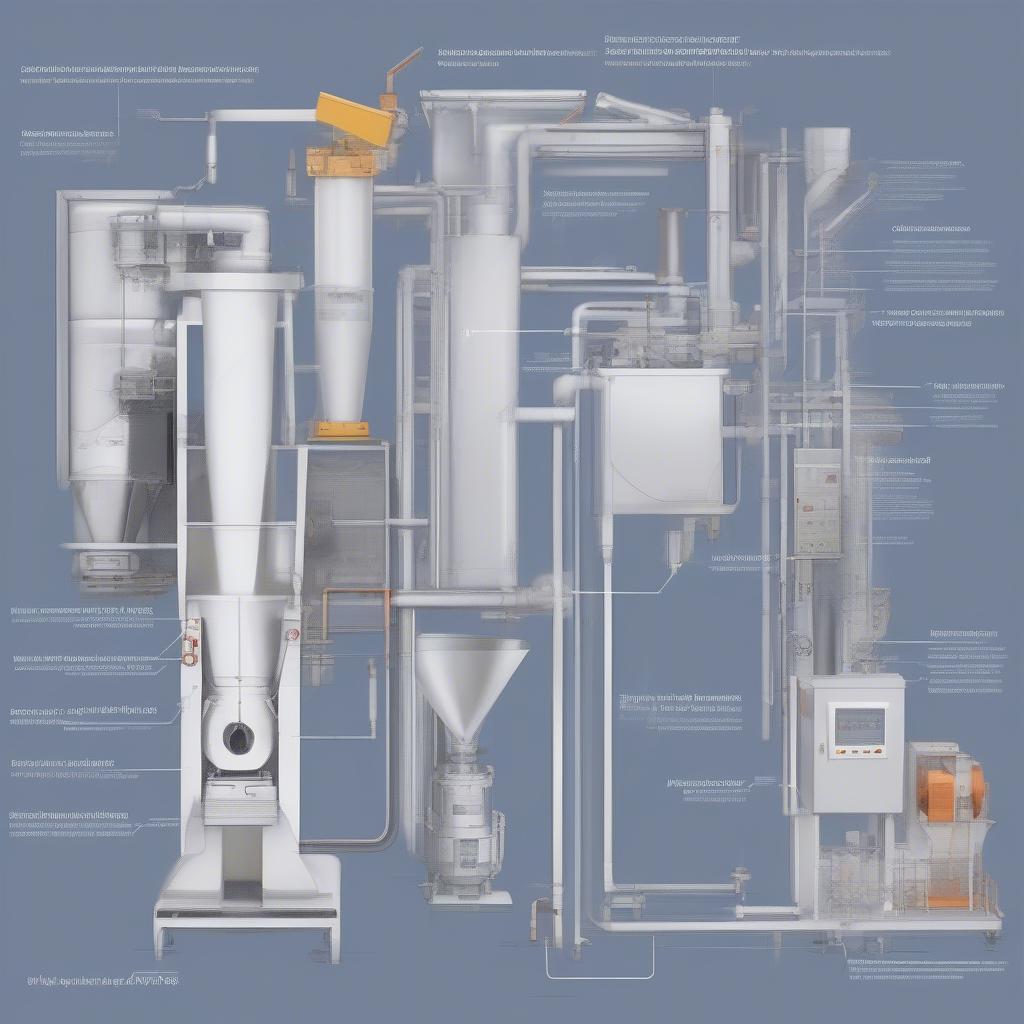

PP Woven Bag Granulation Line Process

PP Woven Bag Granulation Line Process

Understanding the PP Woven Bag Granulation Process

The granulation process involves several crucial steps. First, the collected PP woven bags are fed into a shredder, breaking them down into smaller pieces. These shredded pieces are then washed to remove any contaminants such as dirt, labels, or other impurities. After washing, the material is dried and then fed into the granulator, where it’s melted and extruded into small pellets, ready for reuse in various applications. Optimizing each stage is key to an efficient PP woven bag granulation line.

Key Components of a PP Woven Bag Granulation Line

Key Components of a PP Woven Bag Granulation Line

Factors Affecting PP Woven Bag Granulation Line Efficiency

Several factors can influence the efficiency of a pp woven bag granulation line. The quality of the input material, the type and condition of the machinery used, and the operational parameters all play significant roles. Regular maintenance and proper training of personnel are also crucial for maintaining optimal performance. Neglecting any of these areas can lead to reduced output, increased energy consumption, and higher operating costs.

Maximizing Output and Minimizing Waste

To maximize output and minimize waste, consider these key strategies: investing in high-quality machinery, optimizing the shredding and washing processes, implementing regular maintenance schedules, and training your operators effectively. By focusing on these areas, you can ensure consistent production of high-quality granules while minimizing downtime and waste.

Choosing the Right Equipment for Your Needs

Selecting the right equipment is paramount for an efficient PP woven bag granulation line. The shredder, washer, dryer, and granulator should be chosen based on your specific requirements, including the volume of material to be processed, the desired granule size, and the available space. Consider factors such as the machine’s capacity, power consumption, and maintenance requirements.

“Choosing the right equipment is the cornerstone of a successful granulation operation,” says John Miller, a leading expert in plastics recycling. “Investing in reliable and efficient machinery will pay off in the long run through increased productivity and reduced operating costs.”

Regular Maintenance of PP Woven Bag Granulation Line

Regular Maintenance of PP Woven Bag Granulation Line

The Importance of Regular Maintenance

Regular maintenance is essential for preventing breakdowns and ensuring the longevity of your PP woven bag granulation line. A well-maintained line will operate smoothly and efficiently, producing consistent results. This includes regular cleaning, lubrication, and inspection of all components.

Troubleshooting Common Issues

Even with the best equipment and maintenance practices, issues can sometimes arise. Common problems include blockages in the shredder or granulator, inconsistent granule size, and excessive noise or vibration. Having a troubleshooting plan in place can help address these issues quickly and effectively, minimizing downtime.

Conclusion

Optimizing your PP woven bag granulation line is crucial for achieving maximum efficiency and minimizing waste. By understanding the process, choosing the right equipment, implementing regular maintenance, and addressing common issues proactively, you can ensure a sustainable and profitable operation. Investing in your pp woven bag granulation line is an investment in a greener future.

FAQ:

- What are the main components of a PP woven bag granulation line?

- How can I improve the efficiency of my granulation line?

- What are the common problems encountered in a PP woven bag granulation line?

- How often should I perform maintenance on my granulation line?

- What factors should I consider when choosing equipment for my granulation line?

- What are the benefits of recycling PP woven bags?

- How can I minimize waste in my granulation process?

Need further assistance? Contact our 24/7 customer support team at Hotline: +84 388 951 999, Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA.