Woven Bag

PP Woven Bag Machine: A Comprehensive Guide

Pp Woven Bag Machines are essential for producing the ubiquitous woven polypropylene bags we see everywhere, from grocery stores to construction sites. These machines are vital for businesses looking to create cost-effective and durable packaging solutions. This guide will delve into the world of PP woven bag machines, exploring their types, features, and benefits, helping you make informed decisions for your business.  PP Woven Bag Machine in Operation

PP Woven Bag Machine in Operation

Understanding the PP Woven Bag Machine

PP woven bag machines transform polypropylene granules into flat yarn, then weave these yarns into sturdy fabric rolls. These rolls are then cut and sewn into bags of various sizes and designs. The process is highly automated, allowing for large-scale production with minimal manual intervention. Investing in a pp woven bag machine price requires careful consideration of several factors, including production capacity, bag specifications, and budget.

Choosing the right machine can significantly impact your production efficiency and profitability. There are various types of PP woven bag machines available, each designed for specific needs and applications. From circular looms for producing tubular fabric to flat looms for creating wider fabric rolls, selecting the appropriate machine is crucial.

Key Features and Benefits of PP Woven Bag Machines

Modern PP woven bag machines boast a range of features designed to optimize production and improve the final product quality. Key features include:

- Automated control systems: These systems allow for precise control over the weaving process, ensuring consistent quality and reducing waste.

- High-speed operation: Many machines can produce hundreds of bags per minute, maximizing output and reducing production time.

- Versatile design options: Modern machines can produce bags in various sizes, shapes, and designs, catering to diverse packaging needs.

- Durability and reliability: Built with robust materials, these machines are designed for continuous operation and require minimal maintenance.

These features translate into several key benefits for businesses:

- Cost-effectiveness: Automated production and high-speed operation reduce labor costs and increase overall efficiency.

- Improved product quality: Precise control systems ensure consistent bag quality and minimize defects.

- Increased production capacity: High-speed operation allows businesses to meet growing demand and expand their market reach.

- Versatility and customization: The ability to produce bags in various designs caters to a wide range of packaging applications.

Beyond these, considering factors like pp woven bag machine with printing capabilities adds another layer of customization and branding potential.

Exploring Different Types of PP Woven Bag Machines

The market offers a variety of PP woven bag machines, each catering to specific production requirements:

- Circular looms: These machines produce tubular fabric, ideal for creating bags like sandbags or agricultural packaging.

- Flat looms: Flat looms create wider fabric rolls, suitable for producing larger bags or fabric for industrial applications.

- Extrusion lines: These lines are responsible for producing the polypropylene yarn used in the weaving process.

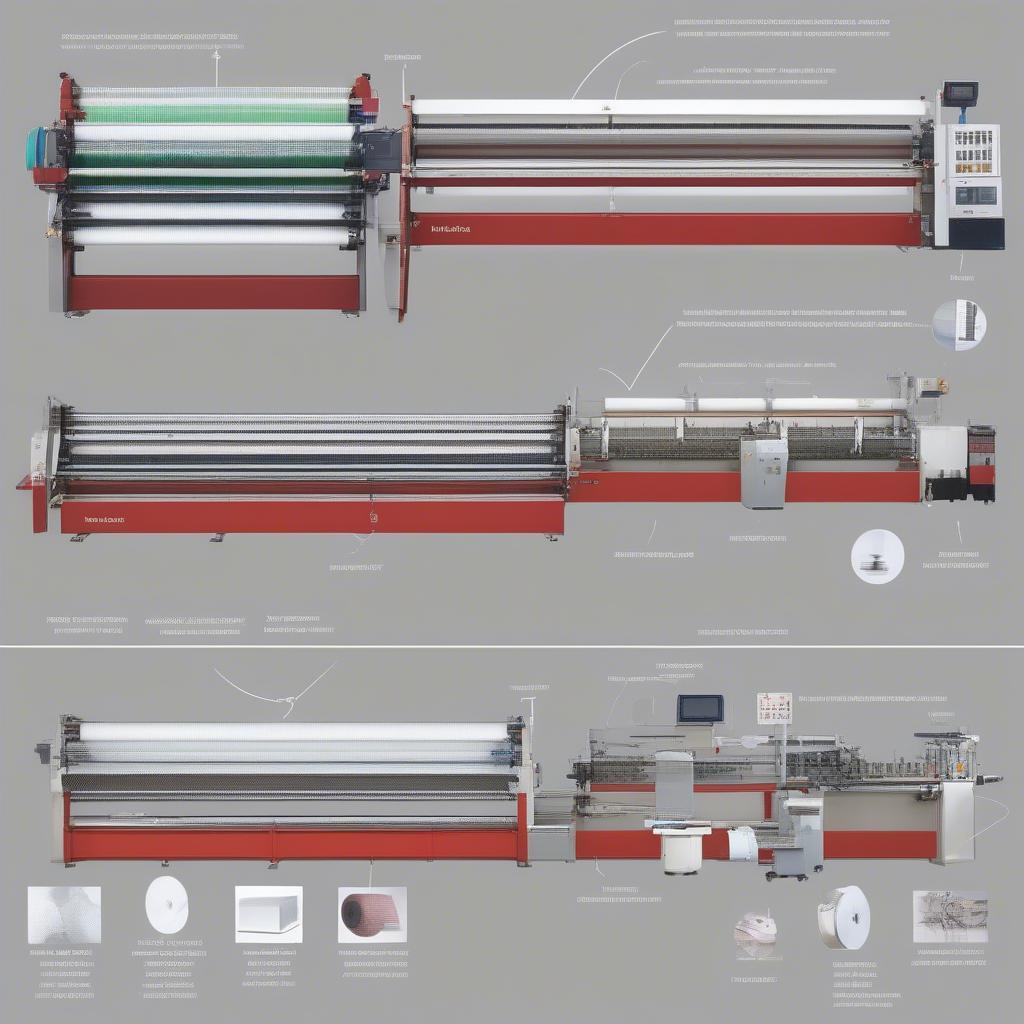

Various PP Woven Bag Machine Models

Various PP Woven Bag Machine Models

Understanding the nuances of each machine type is crucial for selecting the most appropriate option for your business needs. For businesses located in specific regions, resources like pp woven bag machinery india or pp woven bag machinery taiwan can provide valuable insights into local suppliers and market trends.

Maintaining and Optimizing Your PP Woven Bag Machine

Regular maintenance is essential to ensure the longevity and optimal performance of your PP woven bag machine. Routine tasks include cleaning, lubricating moving parts, and inspecting for wear and tear. Having access to pp woven bag machine parts is also crucial for timely repairs and replacements.

Effective maintenance not only prevents costly breakdowns but also ensures consistent product quality and maximizes the lifespan of your investment. Regularly scheduled maintenance also minimizes downtime and maximizes production efficiency.

“Regular maintenance is not an expense; it’s an investment in the long-term productivity and profitability of your operations.” – John Miller, Industrial Machinery Expert.

Conclusion

Investing in a PP woven bag machine is a significant decision for any business involved in packaging. Understanding the various types, features, and benefits can help you choose the right machine for your specific needs and maximize your return on investment. Choosing a PP woven bag machine requires careful consideration of your production requirements, budget, and long-term business goals.

“Choosing the right PP woven bag machine is like selecting the foundation of your packaging operation. A strong foundation leads to a successful and sustainable business.” – Maria Sanchez, Packaging Solutions Consultant.

Frequently Asked Questions (FAQ)

- What are the main types of PP woven bag machines?

- What are the key benefits of using a PP woven bag machine?

- How to maintain a PP woven bag machine?

- What factors should I consider when choosing a PP woven bag machine?

- Where can I find reliable suppliers of PP woven bag machines?

- What are the common problems encountered with PP woven bag machines?

- How can I optimize the performance of my PP woven bag machine?

Maintaining a PP Woven Bag Machine

Maintaining a PP Woven Bag Machine

Have other questions? Need Support? Contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.