Woven Bag

Understanding the PP Woven Cement Bag: A Comprehensive Guide

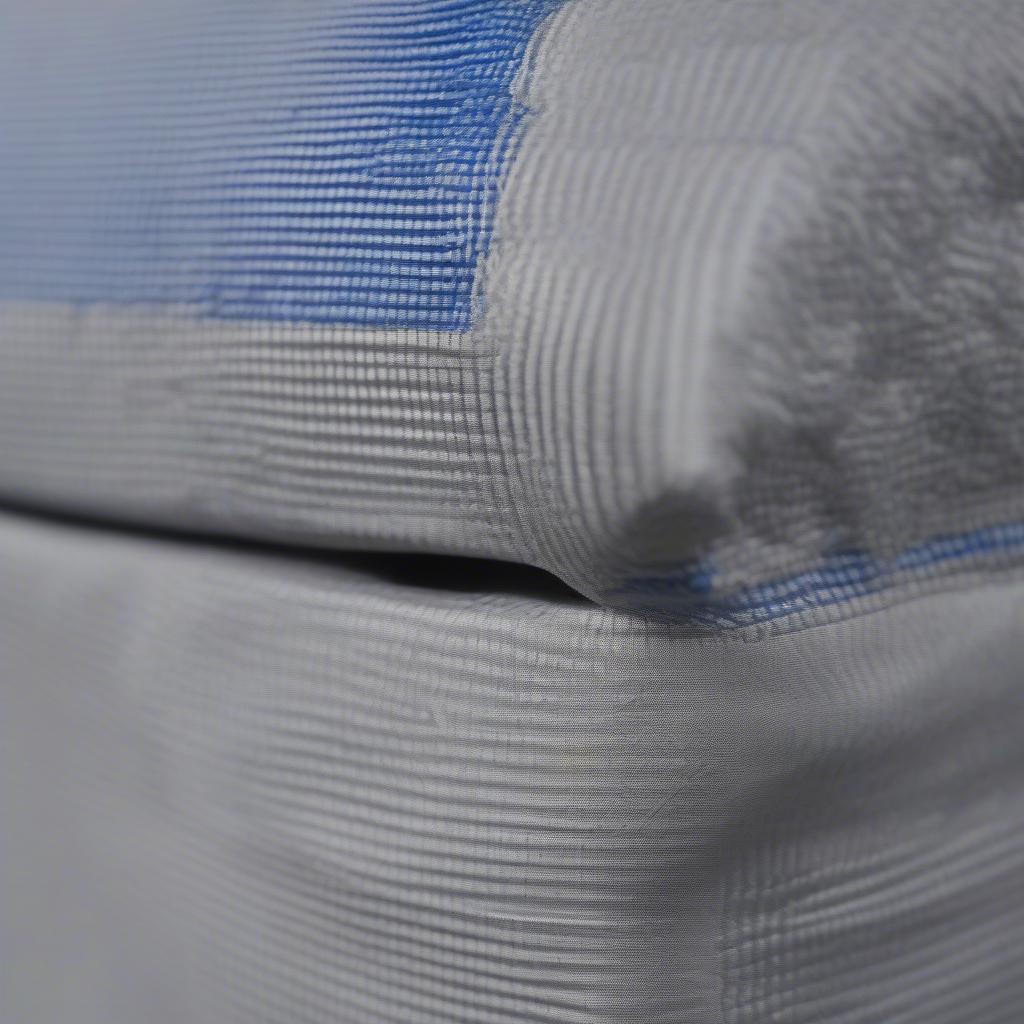

Pp Woven Cement Bags are essential in the construction industry, offering a robust and cost-effective solution for transporting and storing cement. These bags, crafted from woven polypropylene fabric, provide a durable barrier against moisture and external elements, ensuring the quality of the cement inside. From understanding their construction to exploring their various applications, this guide dives deep into the world of pp woven cement bags.  PP Woven Cement Bag Construction Details

PP Woven Cement Bag Construction Details

What is a PP Woven Cement Bag?

PP woven cement bags are made from polypropylene (PP) fabric woven into sheets and then stitched together to form a bag. These bags are designed to hold heavy materials, primarily cement, and are crucial for safe and efficient transportation and storage. They protect the cement from moisture, dust, and other environmental factors that could compromise its quality. Want to learn more about specific types of bags? Check out our guide on pp cement woven bags.

The Benefits of Using PP Woven Cement Bags

These bags boast a range of advantages that make them the preferred choice for cement packaging:

- Durability: The woven polypropylene construction provides exceptional strength, enabling the bags to withstand the rigors of transport and handling.

- Moisture Resistance: The tightly woven fabric acts as a barrier against moisture, safeguarding the cement from humidity and rain.

- Cost-Effectiveness: Compared to other packaging options, pp woven cement bags offer a budget-friendly solution.

- Recyclability: Polypropylene is a recyclable material, contributing to environmentally responsible practices. Looking for reusable bag options? See our article on non woven reusable shopping bags.

How are PP Woven Cement Bags Made?

The manufacturing process involves weaving polypropylene tapes into sheets and then cutting and stitching them into bag shapes. Specialized machinery is used to create these bags efficiently and ensure consistent quality. If you are interested in learning more about the machinery involved, visit our page on pp woven cement bag machine.

Different Types of PP Woven Cement Bags

Several types of pp woven cement bags cater to various needs and preferences:

- Standard PP Woven Bags: These are the most common type, offering a reliable and cost-effective solution for general cement packaging.

- Laminated PP Woven Bags: An additional layer of lamination enhances moisture resistance and durability.

- BOPP Laminated PP Woven Bags: BOPP (Biaxially Oriented Polypropylene) lamination adds a glossy finish and improved printability.

- Ventilated PP Woven Bags: These bags have small perforations to allow for air circulation, particularly useful for certain types of cement.

How to Choose the Right PP Woven Cement Bag?

Selecting the appropriate bag depends on factors such as the type of cement, storage conditions, and transportation requirements. Consulting with a packaging expert can ensure the optimal choice for specific needs. You can explore more about different woven bags on our woven shipping bags page.

Proper Storage and Handling of PP Woven Cement Bags

Proper storage is crucial for maintaining the integrity of the cement. Store the bags in a cool, dry place, away from direct sunlight and moisture. Ensure proper ventilation to prevent condensation. Stack the bags neatly and avoid overloading pallets.

Proper Storage of PP Woven Cement Bags

Proper Storage of PP Woven Cement Bags

The Future of PP Woven Cement Bags

As the construction industry evolves, so too will the technology behind pp woven cement bags. Innovations in materials and manufacturing processes promise even stronger, more durable, and eco-friendly solutions in the future. For more information on various pp woven bag types, visit our page on pp woven bag.

Conclusion

PP woven cement bags remain a cornerstone of the construction industry, offering a dependable and efficient solution for cement packaging. Understanding their construction, benefits, and proper handling ensures optimal performance and contributes to the success of construction projects. Choosing the right pp woven cement bag is essential for protecting the quality of your cement and streamlining your operations.

FAQ

-

What are the dimensions of a standard pp woven cement bag?

-

How much weight can a pp woven cement bag typically hold?

-

Are pp woven cement bags reusable?

-

What is the lifespan of a pp woven cement bag?

-

How can I recycle pp woven cement bags?

-

What are the alternatives to pp woven cement bags for cement packaging?

-

How do I identify a high-quality pp woven cement bag?

Common Scenarios and Questions

-

Scenario: A construction company needs to transport cement over long distances in humid conditions.

-

Question: What type of pp woven cement bag would be most suitable for this scenario?

-

Scenario: A cement manufacturer wants to improve the branding on their packaging.

-

Question: What type of printing is best for pp woven cement bags?

Further Exploration

Explore other related articles on our website for more information on packaging solutions and industry best practices.

Contact Us

For any inquiries or assistance regarding pp woven cement bags, please contact us at:

Hanoi, Vietnam

or

Tech Avenue, Suite 12, San Francisco, CA 94105, USA.

Our customer service team is available 24/7 to address your needs.