Woven Bag

Wholesale Non Woven Bag Making Machine: A Comprehensive Guide

Investing in a Wholesale Non Woven Bag Making Machine can be a game-changer for your business. Whether you’re a seasoned manufacturer or just starting out, understanding the nuances of these machines is crucial for maximizing efficiency and profitability. This guide will delve into everything you need to know about wholesale non woven bag making machines, from the different types available to key features and factors to consider before purchasing.  Non-woven bag making machine operating at high speed in a modern factory setting, producing a large quantity of bags.

Non-woven bag making machine operating at high speed in a modern factory setting, producing a large quantity of bags.

Types of Wholesale Non Woven Bag Making Machines

There are various types of non woven bag making machines designed to cater to different production needs and bag styles. Some common types include:

- Fully Automatic Machines: These machines offer high-speed production with minimal manual intervention, ideal for large-scale operations.

- Semi-Automatic Machines: These machines require some manual input, offering a balance between automation and cost-effectiveness.

- Specialized Machines: These machines are designed for specific bag types, such as non woven goodie bag or non-woven suit cover bag, offering precise customization options.

Key Features to Consider

Choosing the right wholesale non woven bag making machine depends on several crucial factors. Consider these features before making your investment:

- Production Speed: Evaluate your output requirements and choose a machine with the appropriate production speed.

- Bag Size and Style: Different machines are designed for different bag dimensions and styles, from simple tote bags to more complex designs.

- Automation Level: Decide on the level of automation you need based on your budget and workforce.

- Material Compatibility: Ensure the machine is compatible with the type of non-woven fabric you plan to use.

- Maintenance and Support: Choose a reputable supplier offering reliable after-sales service and technical support.

“A reliable non woven bag making machine is an investment that pays off in the long run,” says industry expert, Amelia Cartwright, Head of Manufacturing at EcoBags Inc. “Choosing the right machine can significantly impact your production efficiency and overall profitability.”

Factors Influencing Your Purchase Decision

Beyond the technical specifications, several other factors can influence your purchasing decision:

- Budget: Set a realistic budget and explore options within your price range.

- Space Requirements: Consider the physical space available in your facility to accommodate the machine.

- Energy Consumption: Opt for energy-efficient machines to minimize operational costs.

- Supplier Reputation: Choose a supplier with a proven track record of delivering high-quality machines and excellent customer service.

A modern production line with multiple non-woven bag making machines working simultaneously, highlighting the efficiency and scale of automated bag production.

A modern production line with multiple non-woven bag making machines working simultaneously, highlighting the efficiency and scale of automated bag production.

Understanding the Benefits of Non Woven Bags

Non-woven bags are increasingly popular due to their eco-friendly nature and durability. Investing in a non woven bag with handle making machine allows you to tap into this growing market. “Consumers are increasingly conscious of their environmental impact,” notes David Miller, Sustainability Consultant at Green Solutions Ltd. “Non-woven bags offer a reusable and sustainable alternative to traditional plastic bags, making them a responsible choice for businesses and consumers alike.” This shift in consumer preference makes investing in a wholesale non woven bag making machine a strategically sound decision. You can explore creating diverse options, from a basic non woven cloth bag to specialized designs.

Wholesale Non Woven Bag Making Machine: Return on Investment

Investing in a wholesale non woven bag making machine offers a substantial return on investment through:

- Increased Production Capacity: Automate your production process and significantly increase your output.

- Reduced Labor Costs: Minimize manual labor and reduce associated costs.

- Improved Product Quality: Ensure consistent quality and reduce defects with automated processes.

- Meeting Market Demand: Respond quickly to market demands and capitalize on emerging trends.

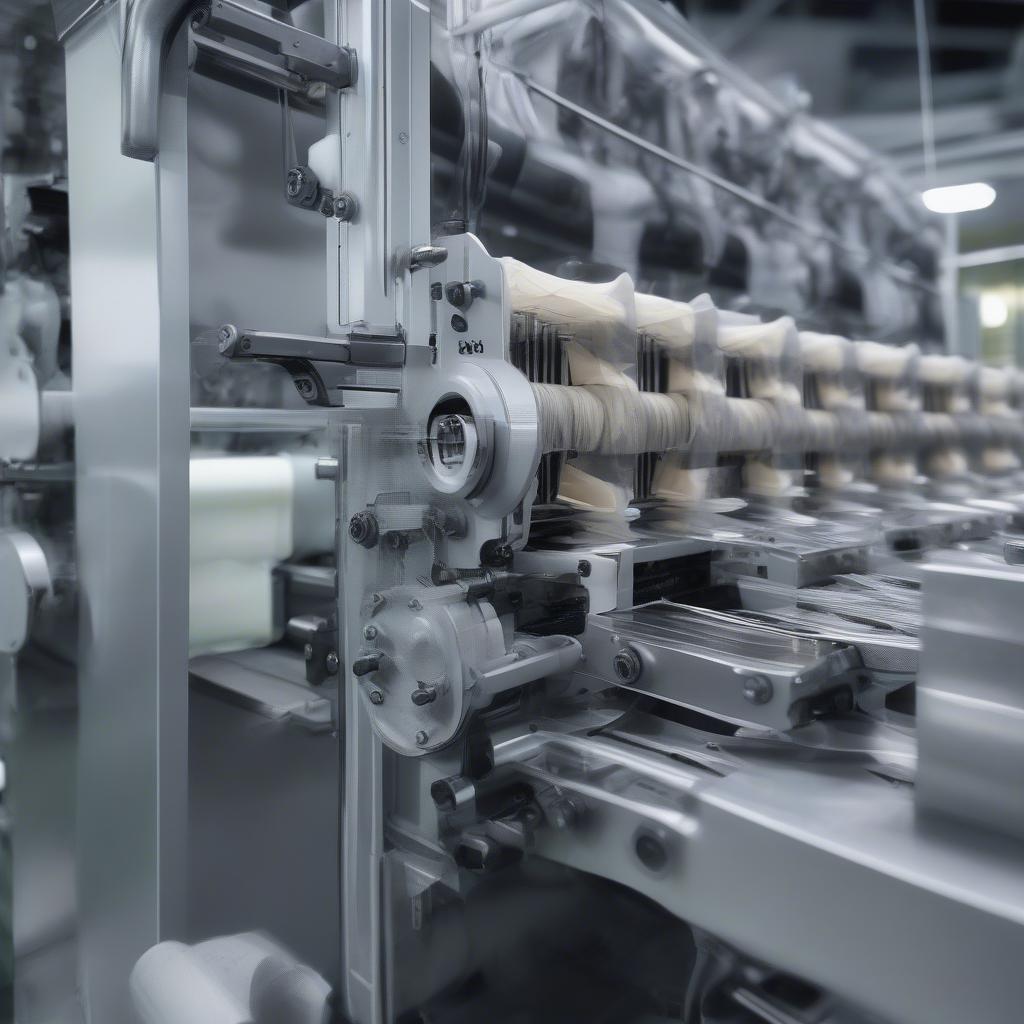

Close-up view of the intricate mechanisms within a non-woven bag making machine, showcasing the precision and complexity of the manufacturing process.

Close-up view of the intricate mechanisms within a non-woven bag making machine, showcasing the precision and complexity of the manufacturing process.

Conclusion

Investing in a wholesale non woven bag making machine is a significant step towards enhancing your production capabilities and meeting the growing demand for sustainable bag solutions. Carefully considering the factors outlined in this guide will help you make an informed decision and choose the machine that best suits your business needs. By understanding the nuances of wholesale non woven bag making machines, you can position your business for success in the thriving non-woven bag market.

FAQ

- What is the average lifespan of a non-woven bag making machine?

- What are the maintenance requirements for these machines?

- What are the different types of non-woven fabrics compatible with these machines?

- How much space is typically required to house a non-woven bag making machine?

- What is the average return on investment for these machines?

- Are financing options available for purchasing these machines?

- What safety features are incorporated in these machines?

Looking for more information on specific woven bag options? Check out our article on woven bag target.

When you need assistance, please contact our Hotline: +84 388 951 999, or visit our offices in Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.