Woven Bag

Wholesale PP Woven Bag Extruder Machine: A Comprehensive Guide

Wholesale Pp Woven Bag Extruder Machines are essential for businesses looking to produce high-quality woven polypropylene bags efficiently. These machines play a crucial role in transforming polypropylene resin into flat yarn, the building block of these versatile bags. Understanding the nuances of these machines, from their technical specifications to their market impact, is critical for making informed purchasing decisions and optimizing production processes.

Wholesale PP Woven Bag Extruder Machine: An Overview

Wholesale PP Woven Bag Extruder Machine: An Overview

Understanding the PP Woven Bag Extruder Machine

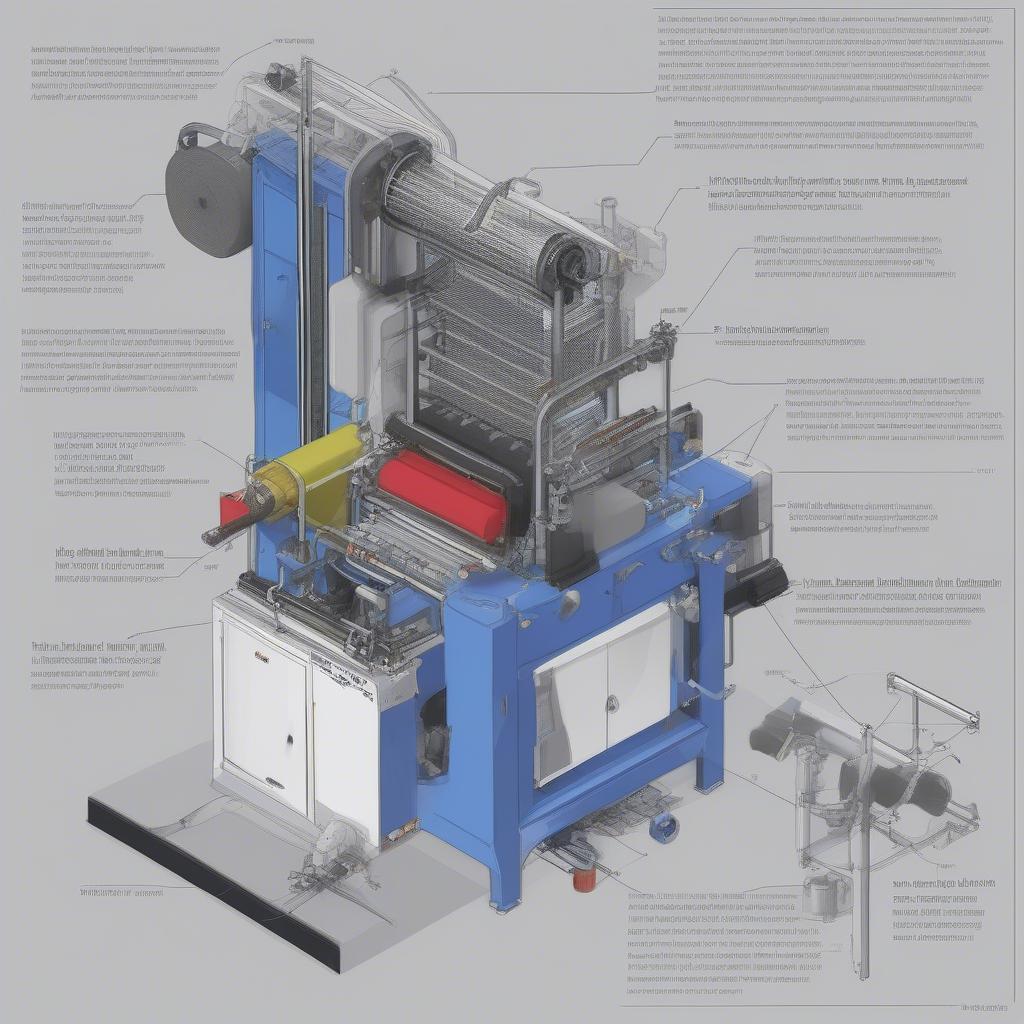

A PP woven bag extruder machine is the heart of the pp woven bag production process, responsible for melting polypropylene pellets and extruding them into thin, flat tapes. These tapes are then woven together to create the durable fabric used in a wide variety of applications, from shopping bags to industrial packaging. Choosing the right wholesale extruder machine is a significant investment, impacting both the quality and quantity of your output.

Key Features and Specifications

Several factors determine the effectiveness of a wholesale PP woven bag extruder machine. These include the machine’s output capacity, the width and thickness of the tapes it produces, and its energy efficiency. Modern machines often incorporate advanced features like automatic temperature control and precise tension regulation, contributing to a more consistent and high-quality end product.

Key Components of a PP Woven Bag Extruder Machine

Key Components of a PP Woven Bag Extruder Machine

Choosing the Right Wholesale PP Woven Bag Extruder Machine

Selecting the appropriate extruder machine for your business requires careful consideration of your specific needs. Factors such as your desired production volume, the types of bags you plan to manufacture, and your budget will influence your decision. Consulting with industry experts can provide valuable insights and guidance in navigating the complexities of the market.

Factors to Consider

- Production Capacity: How many bags do you need to produce per hour/day/week?

- Tape Specifications: What width and thickness of tapes are required for your specific bag types?

- Automation Level: Do you need a fully automated machine or one with manual controls?

- Energy Efficiency: How much energy does the machine consume, and what are the long-term operating costs?

- Supplier Reputation: Is the supplier reliable and reputable, offering good after-sales service and support?

“Choosing the right extruder machine is a foundational decision for any woven bag manufacturer. It’s essential to carefully evaluate your production needs and invest in a machine that aligns with your long-term business goals,” says John Miller, a seasoned production engineer with 20 years of experience in the plastics industry.

Benefits of Investing in a High-Quality Extruder Machine

Investing in a high-quality wholesale PP woven bag extruder machine offers significant advantages. These include increased production efficiency, improved product quality, reduced waste, and lower operating costs. A reliable machine also minimizes downtime and maintenance requirements, contributing to a more streamlined and profitable operation.

Benefits of Investing in a High-Quality Extruder Machine

Benefits of Investing in a High-Quality Extruder Machine

Conclusion: Maximizing Your Investment in a Wholesale PP Woven Bag Extruder Machine

Choosing the right wholesale PP woven bag extruder machine is a crucial step for any business in the woven packaging industry. By carefully evaluating your needs and understanding the key features and specifications of these machines, you can make an informed investment that optimizes your production process and drives long-term success.

“A well-maintained and properly operated extruder machine is a cornerstone of a successful woven bag operation. Regular maintenance and operator training are crucial for maximizing the lifespan and performance of your equipment,” adds Maria Sanchez, a consultant specializing in optimizing production processes within the packaging industry.

Need help choosing the right wholesale PP woven bag extruder machine? Contact our hotline at +84 388 951 999, or visit our offices in Hanoi, Vietnam, or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team ready to assist you.