Woven Bag

Woven Filter Bags: A Comprehensive Guide

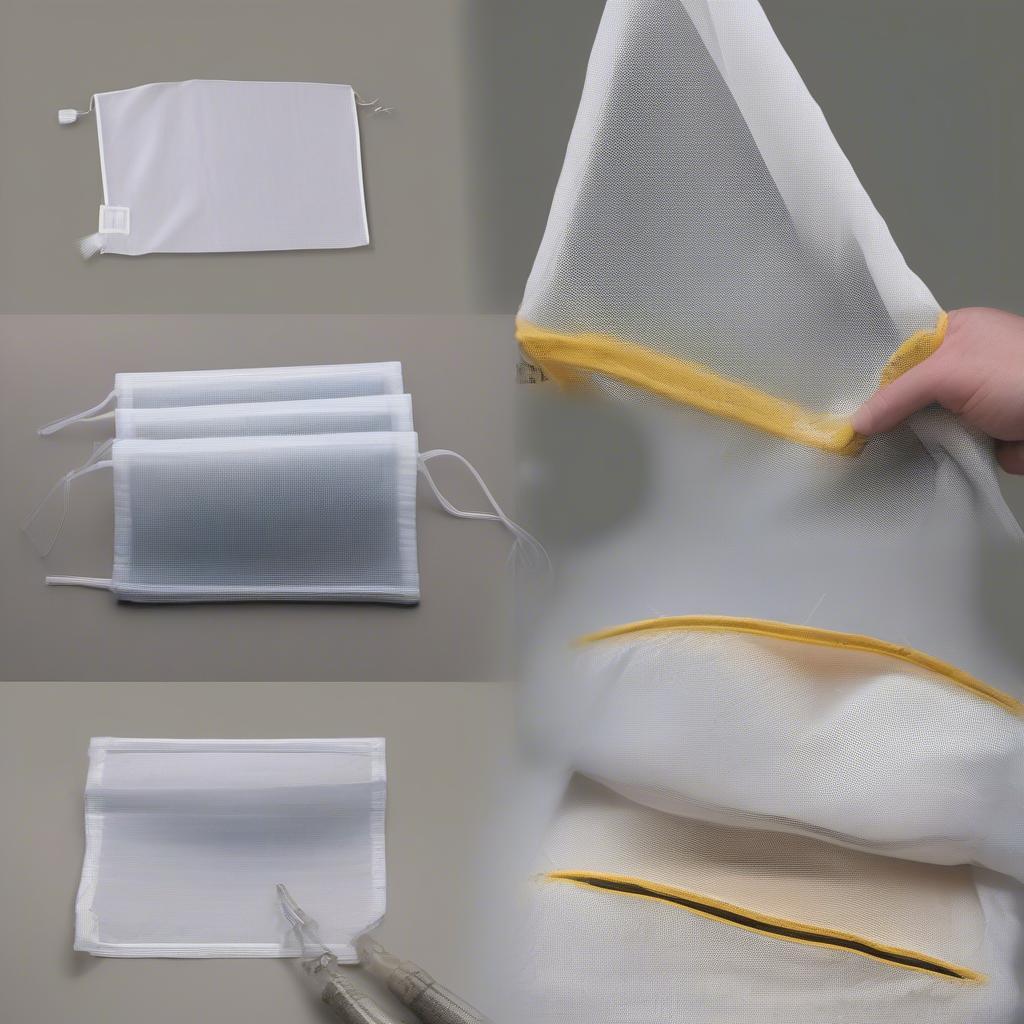

Woven Filter Bags are essential components in various filtration systems, offering a reliable solution for separating solids from liquids or gases. They are known for their durability, efficiency, and versatility across industries. This guide delves into the world of woven filter bags, exploring their types, applications, benefits, and selection criteria. factory hot sale standard non-woven filter bags

Understanding Woven Filter Bags

Woven filter bags are meticulously crafted from various yarns, including polypropylene, polyester, and nylon. The weaving process creates a strong, porous fabric that effectively traps particles while allowing the filtered medium to pass through. These bags come in various sizes, shapes, and micron ratings to cater to diverse filtration needs.

What are the key advantages of using woven filter bags?

- Durability: Woven fabrics are inherently strong, capable of withstanding high pressure and temperatures.

- Efficiency: The tight weave ensures efficient particle removal, providing a high-quality filtrate.

- Versatility: Woven filter bags find applications across a wide range of industries, from food and beverage processing to chemical manufacturing.

- Reusable: Many woven filter bags are designed for repeated use, making them a cost-effective filtration solution.

Types of Woven Filter Bags

Types of Woven Filter Bags

Types of Woven Filter Bags

Several types of woven filter bags are available, each designed for specific applications:

Polypropylene Woven Filter Bags

Polypropylene woven filter bags are widely used due to their chemical resistance and affordability. They are suitable for applications involving acids, alkalis, and solvents.

Polyester Woven Filter Bags

Polyester woven filter bags offer excellent strength and temperature resistance. They are commonly used in high-temperature filtration processes. kubota reusable non woven filter bag

Nylon Woven Filter Bags

Nylon woven filter bags are known for their exceptional abrasion resistance and durability. They are ideal for applications involving abrasive materials.

Applications of Woven Filter Bags

Woven filter bags play a critical role in numerous industries:

- Chemical Processing: Filtering chemicals and removing impurities.

- Food and Beverage: Clarifying liquids and separating solids.

- Pharmaceutical: Ensuring sterile filtration in drug production.

- Water Treatment: Removing sediment and other contaminants from water.

- Dust Collection: Capturing dust and particulate matter in industrial settings. non-woven filter bag

Applications of Woven Filter Bags

Applications of Woven Filter Bags

Choosing the Right Woven Filter Bag

Selecting the appropriate woven filter bag depends on several factors:

- Micron Rating: The micron rating determines the size of particles that the bag can filter.

- Material: The bag material should be compatible with the filtered medium.

- Temperature and Pressure: The bag must withstand the operating temperature and pressure.

- Bag Size and Shape: The bag dimensions should fit the filtration equipment.

“Choosing the right woven filter bag can significantly impact the efficiency and cost-effectiveness of your filtration system,” says filtration expert, Dr. Anya Sharma, Ph.D. in Chemical Engineering. “Consider all relevant factors, and don’t hesitate to consult with a specialist for guidance.” non woven filter bags manufacturer

Maintaining Woven Filter Bags

Proper maintenance is crucial for maximizing the lifespan and performance of woven filter bags. Regular cleaning, inspection, and timely replacement can prevent costly downtime and ensure optimal filtration efficiency. “Regularly inspecting your woven filter bags is key to preventing unexpected failures and maintaining consistent filtration performance,” adds Dr. Sharma.

Maintaining Woven Filter Bags

Maintaining Woven Filter Bags

Conclusion

Woven filter bags offer a robust and versatile filtration solution across various industries. Understanding the different types, applications, and selection criteria is crucial for choosing the right bag for your specific needs. By selecting the appropriate woven filter bag and implementing proper maintenance procedures, you can ensure efficient and cost-effective filtration for your operations. dust collection woven/non woven filter bags Remember to consult with experts like Dr. Sharma for personalized advice on your filtration needs.

FAQ

- What is the difference between woven and non-woven filter bags?

- How do I determine the correct micron rating for my application?

- Can woven filter bags be reused?

- What are the common causes of woven filter bag failure?

- How often should I replace my woven filter bags?

- What are the best practices for cleaning woven filter bags?

- Where can I purchase high-quality woven filter bags?

When you need support, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer service team.