Woven Bag

Woven Filter Bags: A Comprehensive Guide

Woven Filter Bags are essential components in various industries, offering a reliable and efficient filtration solution. This guide delves into the world of woven filter bags, exploring their applications, benefits, materials, and selection process. Let’s begin our exploration of these vital filtration tools.

Woven Filter Bags in Industrial Applications

Woven Filter Bags in Industrial Applications

Understanding Woven Filter Bags: Types and Applications

Woven filter bags are designed for a wide range of filtration applications across diverse industries. From food and beverage processing to chemical manufacturing and pharmaceuticals, these bags play a crucial role in maintaining product quality and protecting equipment. They are particularly useful for separating solids from liquids or gases, ensuring a clean and efficient process.

Types of Woven Filter Bags

Woven filter bags are available in a variety of materials, each suited to specific applications. Common materials include polypropylene, polyester, nylon, and specialized fibers like Nomex and PTFE. fiberglass woven filter bags manufacturer produce bags designed for high-temperature applications. The choice of material depends on the nature of the fluid being filtered, the temperature, and the chemical compatibility requirements.

Key Applications of Woven Filter Bags

- Chemical Processing: Woven filter bags are crucial for filtering chemicals, removing impurities, and ensuring product purity.

- Food and Beverage: These bags are essential in filtering liquids and ingredients in food and beverage production.

- Pharmaceutical Industry: Woven filter bags help maintain sterile conditions and filter pharmaceutical products.

- Wastewater Treatment: In wastewater treatment plants, these bags filter out solid waste, contributing to cleaner water discharge.

- Dust Collection: Woven filter bags are used in dust collection systems to capture airborne particles and maintain air quality.

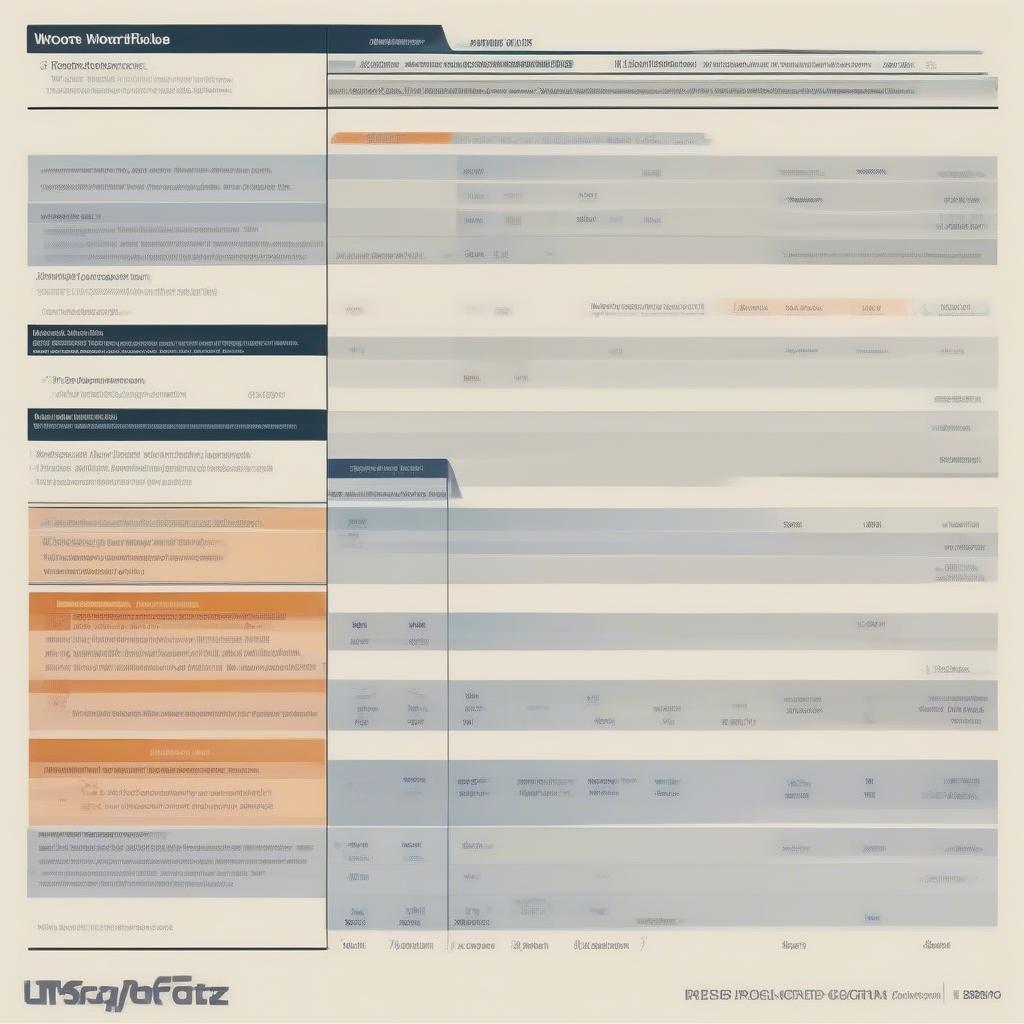

Comparing Woven Filter Bag Materials

Comparing Woven Filter Bag Materials

Benefits of Using Woven Filter Bags

Why choose woven filter bags over other filtration methods? There are several compelling reasons:

- High Efficiency: Woven filter bags offer excellent filtration efficiency, effectively removing even fine particles.

- Durability and Reusability: Many woven filter bags are reusable, providing a cost-effective solution. They can withstand harsh conditions and repeated cleaning cycles.

- Easy Installation and Replacement: These bags are designed for easy installation and replacement, minimizing downtime.

- Versatility: Woven filter bags are available in various sizes and materials to suit different filtration needs. You can even find a dedicated woven filter bags factory to cater to your specific requirements.

- Cost-Effectiveness: Compared to other filtration methods, woven filter bags offer a relatively low cost of ownership.

“When it comes to robust and reliable filtration, woven filter bags are a top choice. Their versatility and efficiency make them ideal for a wide range of applications,” says filtration expert, Dr. Anya Sharma, Senior Research Scientist at Filtration Solutions Inc.

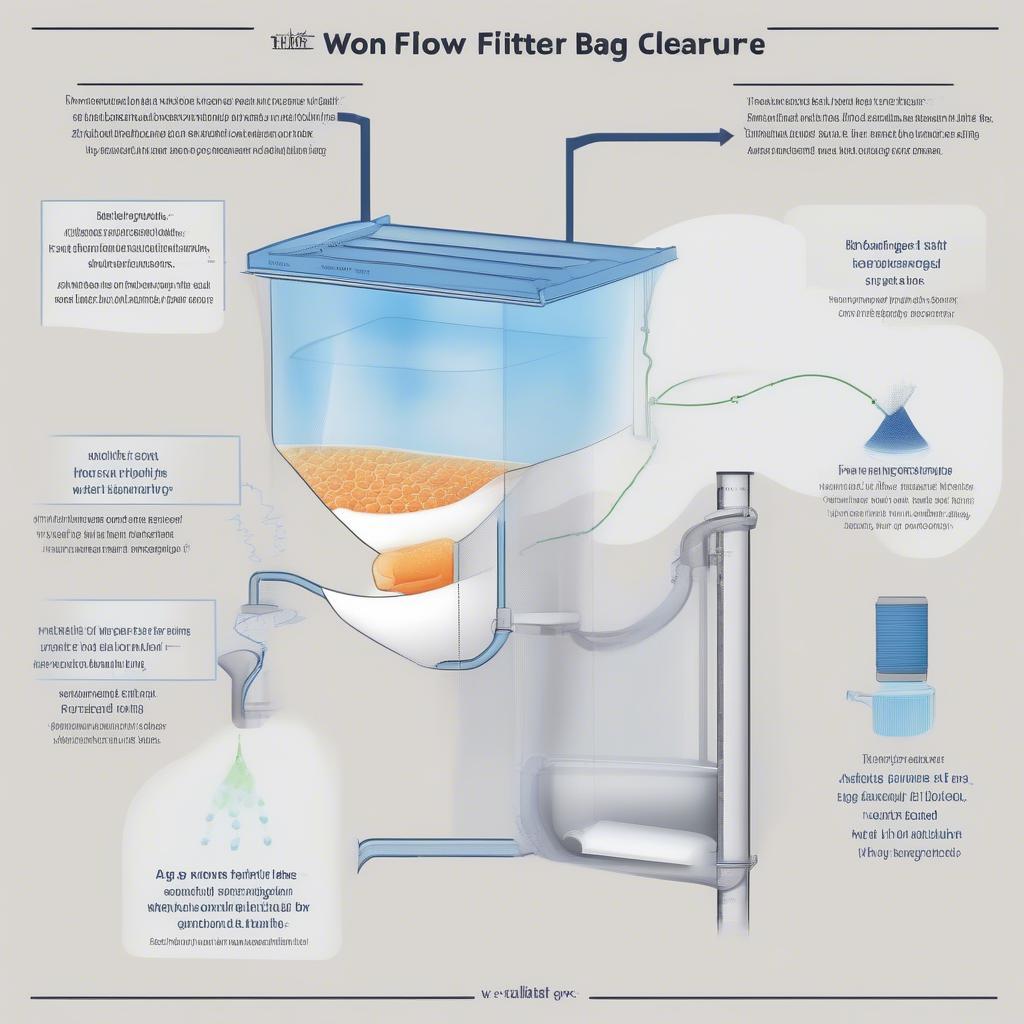

Woven Filter Bag Filtration Process

Woven Filter Bag Filtration Process

Selecting the Right Woven Filter Bags

Choosing the right woven filter bags requires careful consideration of several factors:

Material Compatibility

The material of the bag must be compatible with the fluid being filtered to prevent chemical reactions or degradation. Non woven filter bags are another option available on the market. Considering a fiberglass non woven filter bags manufacturer can be beneficial if you require high-temperature resistance.

Micron Rating

The micron rating determines the size of particles the bag can filter. Choosing the appropriate micron rating is critical for achieving the desired filtration efficiency.

Bag Size and Design

The size and design of the bag should be chosen based on the flow rate and volume of the fluid being filtered.

Conclusion: Optimizing Filtration with Woven Filter Bags

Woven filter bags are an essential part of many industrial processes, providing efficient and reliable filtration. By understanding the different types, benefits, and selection criteria, you can optimize your filtration process and ensure product quality. Choosing the right woven filter bags ensures effective contaminant removal, leading to improved product quality and process efficiency.

FAQ

- What are the main advantages of using woven filter bags?

- How do I choose the right micron rating for my application?

- What are the common materials used in woven filter bags?

- How often should woven filter bags be replaced?

- Are woven filter bags reusable?

- Where can I find a reliable woven filter bags supplier?

- What is the difference between woven and non woven filter bag?

If you need further assistance, please contact us at Hanoi, Vietnam or Tech Avenue, Suite 12, San Francisco, CA 94105, USA. We have a 24/7 customer support team.